261

Inspections Section 10-1

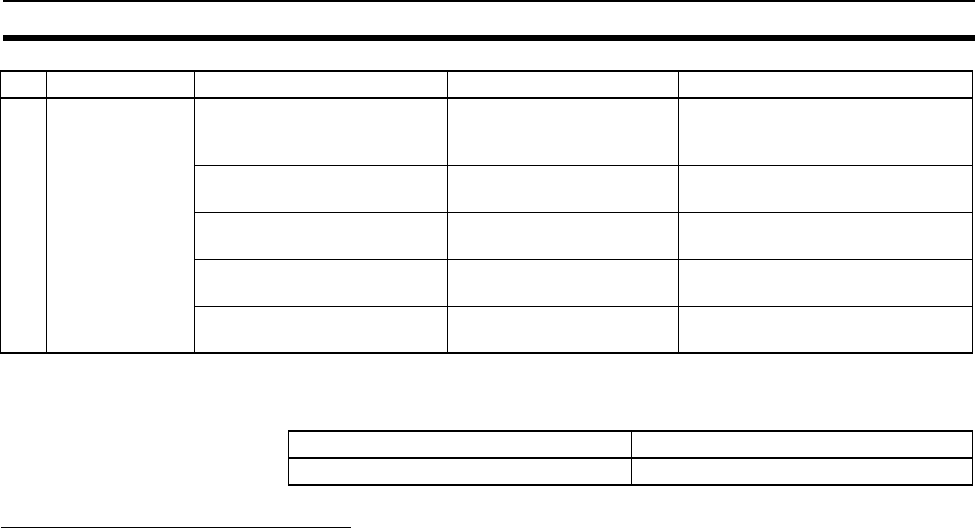

Note The following table shows the allowable voltage fluctuation ranges for source

power supplies.

Tools Required for Inspections

Required Tools • Phillips-head screwdriver

• Voltage tester or digital multimeter

• Industrial alcohol and clean cotton cloth

Tools Required

Occasionally

• Synchroscope

• Oscilloscope with pen plotter

• Thermometer and hygrometer (humidity meter)

10-1-2 Module Replacement Precautions

Check the following after replacing any faulty Module.

• Do not replace a Module until the power is turned OFF.

• Check the new Module to make sure that there are no errors.

• If a faulty Module is being returned for repair, describe the problem in as

much detail as possible, enclose this description with the Module, and

return the Module to your OMRON representative.

• For poor contact, take a clean cotton cloth, soak the cloth in industrial

alcohol, and carefully wipe the contacts clean. Be sure to remove any lint

prior to remounting the Module.

Note (1) When replacing a Coordinator Module or Motion Control Module, be sure

that not only the user program but also all other data required for opera-

tion is transferred to or set in the new Coordinator Module before starting

operation, including DM Area and System Setup settings. If data area and

other data are not correct for the user program, unexpected operation or

accidents may occur.

(2) The System Setup is stored in the parameter area within the Coordinator

Module or Motion Control Module. Be sure to transfer these settings to

the new Coordinator Module or Motion Control Module when replacing a

Module.

(3) After replacing a Motion Control Module, always set the required settings.

(4) In some cases, parameter data used in the Motion Control Modules is ac-

tually stored in the Coordinator Module’s DM Area, so be sure to transfer

the DM Area settings when replacing a Coordinator Module.

4 Installation and

wiring

Check that each Module is

connected and locked to the

next Module securely.

No looseness Press the connectors together

completely and lock them with the

sliding latches.

Check that cable connectors

are fully inserted and locked.

No looseness Correct any improperly installed

connectors.

Check for loose screws in

external wiring.

No looseness Tighten loose screws with a Phil-

lips-head screwdriver.

Check crimp connectors in

external wiring.

Adequate spacing between

connectors

Check visually and adjust if neces-

sary.

Check for damaged external

wiring cables.

No damage Check visually and replace cables if

necessary.

Supply voltage Allowable voltage range

100 to 240 V AC 85 to 264 V AC

No. Item Inspection Criteria Action