505429-JTG-F-1010

6 Johnson Controls Unitary Products

been mechanically expanded into aluminum fins. Both

headers are located on the same end of the coil. The coil is

leak-tested at 325 psig and dried before the connections are

capped for storage and shipping.

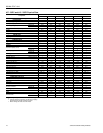

Guide Specifications

Split System Cooling Only Condensing Units

Models: J07 thru 25YC, J10 thru 20YD & Split

System Heat Pump Models: J07 thru 25PC, J15 thru

20PD

General

• Factory assembled, single piece, air cooled condensing

unit designed for outdoor installation.

• Factory wired, piped, and tested for leakage and

functionality to assure trouble-free installation and start-

up.

• Rated in accordance with ARI Standard 340/360.

• Manufactured in a facility registered under the ISO 9002

manufacturing quality standard.

• Designed and tested in accordance with ASHRAE 15

Safety Code for Mechanical Refrigeration and comply

with NEC.

• Cooling performance rated in accordance with DOE

and ARI test procedures.

• CSA listed and classified to UL 1995/CAN/CSA No.

236- M90 standards.

• One year limited parts warranty on complete unit with

an additional four year compressor warranty.

Unit Operating Characteristics

Operating Range shall be between 125° F to 40° F in cooling

as standard from factory.

• The capacity of the condensing unit shall meet or

exceed _____ Btuh at a suction temperature of _____

F. The power consumption at full load shall not exceed

_____ kW.

• The combination of the condensing unit and the

evaporator or fan coil unit shall have a total net cooling

capacity of _____ Btuh or greater at conditions of

_____ cfm entering-air temperature at the evaporator at

_____ F wet bulb and _____ F dry bulb, and air

entering the condensing unit at _____F.

• The system shall have an EER of _____ Btuh/ Watt or

greater at standard ARI conditions.

Installer Shall

• Furnish JCI® air-cooled condensing units, heat pump or

equivalent in accordance with the performance

schedule shown on the plans, and

• Unit shall be stored and handled in accordance with unit

manufacturer's instructions.

• Install each unit as shown on the plans in accordance

with the manufacturer’s recommendations and all

applicable national and local codes

Unit Construction

• Constructed of zinc-coated, galvanized steel.

• Exterior surfaces bonded and coated with baked

enamel finish by a powder paint process capable of

withstanding a minimum of 1000 salt spray hours

according to ASTM B117.

• Cabinet screws that comply with ASTM B117 salt spray

test for a minimum of 750 hours.

• Permanently attached heavy-gage perimeter base rails

with forklift slots and lifting holes.

• Removable access panels to all internal components.

• Separate access panel to controls.

• Access panels to allow outdoor coil cleaning.

Compressor(s)

• Hermetic scroll type, internally protected with high-

pressure relief and over temperature protection.

• Two stage units operate in 50% capacity increments.

• Suction gas cooled

• Voltage range of ±10% of unit nameplate voltage.

• Neoprene isolators minimize sound transmission and

vibration.

• Belly-band crankcase heaters keep refrigerant from

diluting sump oil.

• Full charge of compressor oil

Outdoor Condenser Unit Coils

• Draw thru configuration

• Constructed with Micro-channel aluminum fins and

aluminum tubing. All refrigerant tubing must share a

common header.

Heat Pump Unit Outdoor Unit Coils

• Draw thru configuration

• Constructed with aluminum plate fins mechanically

bonded to seamless internally enhanced copper tubes

with all joints brazed.

Condenser Fans

• Direct driven propeller-type fans

• Statically and dynamically balanced

• Aluminum blades riveted to corrosion resistant steel

spider brackets.

• Arranged for vertical air discharge.

• Equipped with PVC coated steel wire safety guards.