7

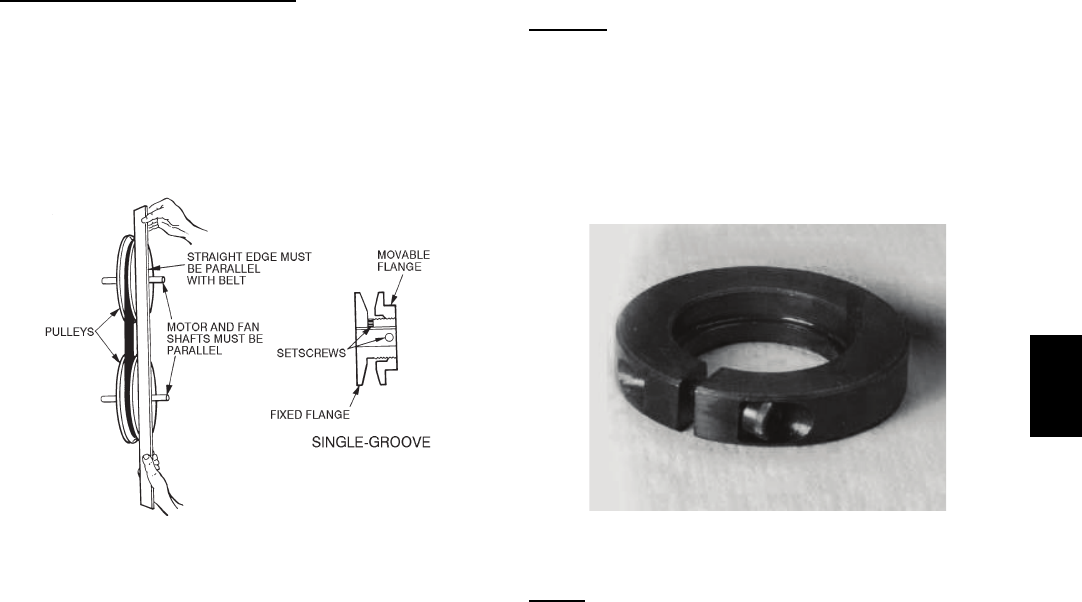

Adjustable--Pitch Pulley on Motor

The motor pulley is an a djustable--pitch type that allows a

servicer to implement changes in the fan wheel speed to

match as--installed ductwork systems. The pulley consists

of a fixed flange side that faces the motor (secured to the

motor shaft) and a movable flange side that can be rotated

around the fixed flange side t hat increase s or re duces the

pitch diameter of this driver pulley. (See Fig. 9.)

C07075

Fig. 9 -- Supply--Fan Pulley Adjust ment

As the pitch diameter is changed by adjusting the position

of the movable flange, the centerline on this pulley shifts

laterally (along the motor shaft). This creates a

requirement for a reali gnment of the pulleys after any

adjustment of the movable flange. Also reset the belt

tension after each realignment.

Check the c ondition of the motor pulley for signs of wear.

Glazing of the belt contact surfaces and erosion on these

surfaces are signs of improper belt tension and/or belt

slippage. Pulley replacement may be necessary.

To change fan speed:

1. Shut off unit power supply.

2. Loosen belt by loosening fan m otor mounting nuts.

(See Fig. 8.)

3. Loosen movable pulley flange setscrew. (See Fig. 9.)

4. Screw movable flange toward fixed flange to increase

speed and away from fixed flange to decrease speed.

Increasing fan speed increases load on motor. Do not

exceed maximum speed specified.

5. Set movable flange at nearest keyway of pulley hub

and tighten setscrew to torque specifications.

To align fan and motor pulleys:

1. Loosen fan pulley setscrews.

2. Slide fan pull ey along fan shaft. Make angular align-

ment by loosening motor from mounting.

3. Tighten fan pulley setscrews and mot or mounting

bolts to torque specifications.

4. Recheck belt te nsion.

Beari ngs

This fan system uses bearings featuring concentric split

locking collars. The collars are tightened through a cap

screw bridging the split portion of the collar. The cap

screw has a Torx T25 socket head. To tighten the locking

collar: Hold the locking collar tightly against the inner

race of the bearing and torque the cap screw to 65--70

in--lb (7.4--7.9 Nm). See Fig. 10.

C08121

Fig. 10 -- Tightening Locking Collar

Motor

When replacing the motor, also replace the external--tooth

lock washer (star washer) under the motor mounting base;

this is part of the motor grounding system. Ensure t he

teeth on the lock washer are in contact with the motor’s

painted base. Tighten motor mounting bolts to 120 +/-- 12

in--lbs.

Changing fan wheel speed by changing pulleys: The

horsepower rating of the belt is primarily dictated by the

pitch diameter of the smaller pulley in the drive system

(typically the motor pulley in t hese uni ts). Do not install a

replacement motor pulley with a smaller pitch diameter

than provided on the original fact ory pulley. Change fan

wheel speed by changing the fan pulley (larger pitch

diameter to reduce wheel speed, smaller pitch diameter to

increase wheel speed) or select a new system (both

pulleys and matching belt(s)).

Before changing pulleys to increase fan wheel speed,

check the fan performance at the target speed and airflow

rate to de termine new motor loading (bhp). Use the fan

performance tables or use the Packaged Rooftop Builder

software program. Confirm that the motor in this unit is

capa ble of operating at the new operating condition. Fan

shaft loading increases dramatically as wheel speed is

increased.

To reduce vibration, replace the mot or’s adjustable pitch

pulley with a fixed pitch pulley (after the final airflow

bala nce adjustment). This will reduce the amount of

vibration generated by the motor/belt--drive system.

548J