21

Overtemperature

The com pressor has an internal protector to protect it

agai nst excessively high discharge gas temper atures.

High Pressure

Switch

The system is provided with a high pressure switch

mounted on t he discharge line. The switch is

stem--mounted and brazed into the discharge tube. Trip

setting is 630 psig +/-- 10 psig (4344 +/-- 69 kPa) when

hot. Reset is automatic at 505 psig (3482 kPa).

Loss of Charge

Switch

The system is protected against a loss of charge and low

evaporator coil loading condition by a loss of charge

switch located on the liquid line and a freeze protection

thermostat on the indoor coil. The switch is

stem-- mounted. Loss of Charge Switch trip setting is

27 psig +/-- 3 psig (186 +/-- 21 kPa). Reset is automatic at

44 +/-- 3 psig (303 +/-- 21 kPa).

Freeze Protection Thermostat trip setting is 30_F+/--5_F

(-- 1_C+/--3_C). Reset is automatic at 45_F+/--5_F(7_C

+/--3_C).

Supply (Indoor) Fan Mot or Protection

Disconnect and lockout power when servi cing fan motor.

2.9 and 3.7 bhp motors are equipped with an

overtemperature or protection device. The type of device

depends on the motor size. See Table 8.

Table 8 – Overload Device per Motor Size

Motor Size ( bhp) Overload Device Reset

1.7 Internal Linebreak Automatic

2.4 Internal Linebreak Automatic

2.9 Thermix Automatic

3.7 Thermix Automatic

4.7

External

(Cir cuit Breaker)

Manual

The High Static option supply fan motor is equipped with

a pilot--circuit Thermix combination overtemperature/

overcurre nt protecti on device. This device resets

automatically. Do not bypass this switch to correct

trouble. Determine the cause and correct it.

The Thermix device is a snap--action overtemperature

protec tion device that is imbedded in the motor windings.

It is a pilot--circuit device that is wired into the unit’s 24–v

control circuit. When this switch reaches its trip setpoint,

it opens the 24–v control circuit and causes all uni t

operation to cease. This device resets automatically when

the motor windings cool. Do not bypass this switch to

correc t trouble. Determine the cause and correct it.

The External motor overload devic e is a

specially--calibrat ed circuit breaker that is UL recognized

as a motor overload controller. It is an overcurrent device.

When the motor current exceeds the circuit breaker

setpoint, the device opens all motor power le ads and the

motor shuts down. Reset requires a manual reset at the

overloa d swi tch. T his device (designated IFCB) is located

on the side of the supply fan housing, behind the fan

access panel.

Troubleshooting supply fan motor overl oad trips: The

supply fan used in 548J units is a forward--curved

centrifugal wheel. At a constant wheel speed, this wheel

had a characteristic that causes the fan shaft load to

DECREASE when the static pressure in the unit--duct

system increases and to INCREASE when the static

pressure in the unit--duct system decre ases (and fan

airflow rate increases). Motor overload conditions

typically develop when the unit is operated with an access

panel removed, with unfinished duct work, in an

econom izer--open mode, or a leak develops in the duct

system that all ows a bypass back to uni t return opening.

Outdoor Fan Motor Protection

The outdoor fan motor is internally protected against

overtemperature.

Control Circuit, 24-- V

The control circui t is protec ted against overcurrent

conditions by a circuit breaker mounted on control

transformer TRAN. Reset is manual.

COMMERCIAL DEF ROST CONTROL

The Commercial Defrost Control Board (DFB)

coordinates thermostat demands for supply fan control, 1

or 2 stage cooling, 2 stage heating, emergency heating and

defrost control with unit operating sequences. The DFB

also provides an indoor fan off delay feature (user

selectable). See Fig. 26 for board arrangement.

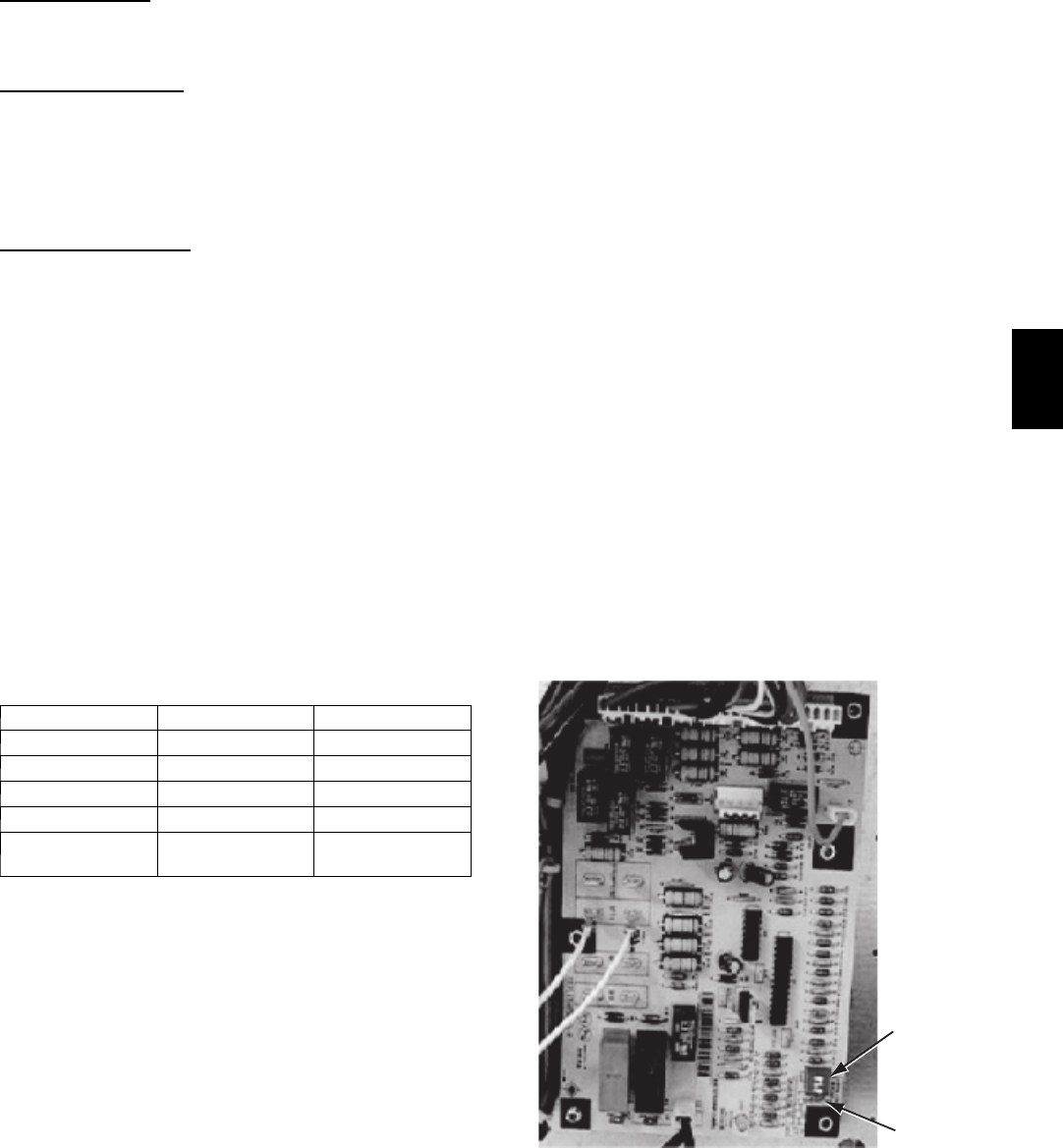

DIP

Switches

Speed-Up

Jumpers

C09275

Fig. 26 -- Defrost Control Board (DFB) Arrangement

The DFB is located in the 548J’s mai n control box (see

Fig. 27). All connections are factory--made through

harnesses to the unit’s CTB, to IFC (belt--drive motor) or

to ECM (direct--drive motor), reversing valve solenoids

and to defrost thermostats. Refer to Table 9 for details of

DFB Inputs and Outputs. Detailed unit operating

sequence s are provided in the Operating Sequences

section starting on page 62.

548J