12

Table 5 – Defrost Mode

04A---07A and 08D---09D/Circuit 2:

Component

Status/Position

Defrost Thermostat Closed

Outdoor Fan(s) Off

Reversing Valve Energized

Check Valve A Closed

Check Valve B Open

Check Valve C Closed

Check Valve D Open

Troubleshooting Refrigerant Pressure Problems

and Check Valves

Refer to Fig. 14, on page 10, and the Cooling Mode and

Heating Mode tables (Tables 3 and 4) on page 11.

Coil Metering

Devices

The metering devices are multiple fixed–bore devices

(Acutrolt) swa ged into the horizontal outlet tubes from

the liquid header, located at the entrance to each

evapora tor coil circuit path. These are non–adjustable.

Service requires replacing the entire liquid header

assembly.

Check for possible blockage of one or more of these

metering devices by creating a low load condition on the

evapora tor--function coil and then observing the frosting

pattern on the finned portion of the coil.

To check the indoor coil, disconnect the supply fan signal

(04A--06A direct--drive fans) or contactor (IFC) coil, then

start the circuit in a Cooling Mode (jumper R to Y1 or

Y2) and observe the frosting pattern on the face of the

indoor coil. A frost pattern should develop uni formly

across the face of the indoor coil starting at each tube at

the Acutrol nipple locations.

To check the outdoor coil, disconnect the outdoor fan

motor. Start the circuit in a Heating Mode (jumper R to

W1 or W2) and observe the frost pattern on the face of the

outdoor coil.

Failure to develop frost at an outle t tube can indicate a

plugged or a missing orifice.

Refrigerant System Pressure Access Ports

There are two access ports in each circuit -- on the suction

tube near the compressor and on the discharge tube near

the compressor. These are brass fittings with black plastic

caps. The hose connection fittings are standard 1/4 SAE

Male Flare couplings.

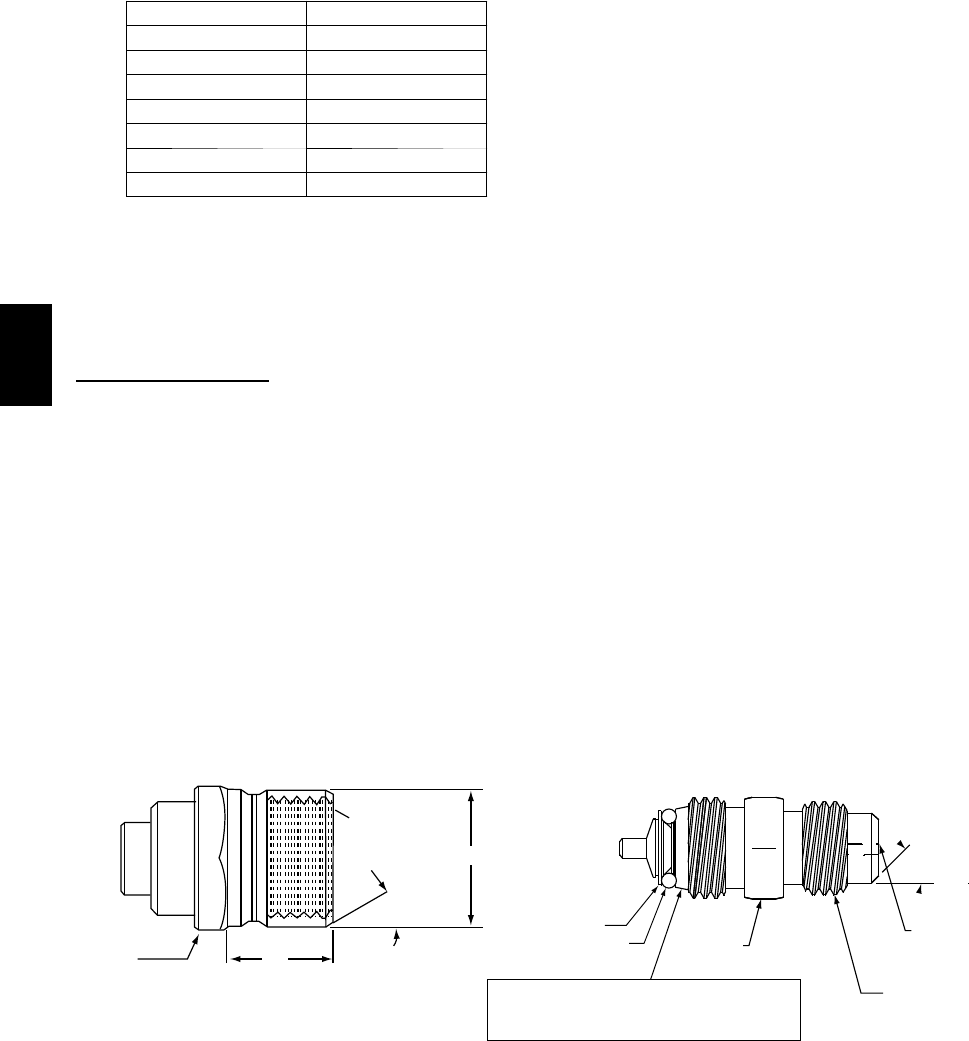

The brass fittings are two-- piece High Flow valves, with a

receptacle base brazed to the tubing and an integral

spring-- closed check valve core screwed into the base.

(See Fig. 19.) This check valve is permanently assembled

into this core body and cannot be serviced separately;

replace the entire c ore body if necessary. Service tools are

available from RCD that allow the replacement of the

chec k va lve c ore without having to recover the entire

system refrigerant charge. Apply compressor refrigerant

oil to the check valve core’s bottom o--ring. Install the

fitting body with 96 +/--10 in--lbs of torque; do not

overtighten.

1/2-20 UNF RH

30°

0.596

.47

5/8” HEX

SEAT

CORE

WASHER

DEPRESSOR PER ARI 720

+.01/-.035

FROM FACE OF BODY

7/16-20 UNF RH

O-RING

45°

1/2" HEX

This surface provides a metal to metal seal when

torqued into the seat. Appropriate handling is

required to not scratch or dent the surface.

(Part No. EC39EZ067)

C08453

Fig. 19 -- CoreMax Access Port Assembly

548J