54

graph with the left side of the chart to determine that the

range configuration for the CO

2

sensor should be 1800

ppm. The EconoMi$er IV controller will output the 6.7

volts from the CO

2

sensor to the actuator when the CO

2

conce ntration in the spac e is at 1100 ppm. The DCV

setpoint may be left at 2 volts since the CO

2

sensor

voltage wi ll be ignored by the EconoMi$er IV controller

until it rises above the 3.6 volt setting of the minimum

position potentiometer.

Once the fully occupied damper position has been

determined, set the maximum damper demand control

ventilation potentiometer to this position. Do not set to the

maximum position as this can result in over-ventilation to

the space and potential high humidity levels.

CO

2

Sensor Configuration

The CO

2

sensor has preset st andard voltage settings that

can be selected anytime after the sensor is powered up.

(See Table 23.)

Use setting 1 or 2 for Bryant equipment. (See Table 23.)

1. Pre ss Clear and Mode buttons. Hold at least 5 seconds

until the sensor enters the Edit mode.

2. Press Mode twice. The STDSET Menu will appear.

3. Use the Up/Down button to select the preset number.

(See Table 23.)

4. Press Enter to lock in the selection.

5. Press Mode to exit and resume normal operation.

The custom settings of the CO

2

sensor can be changed

anytime after the sensor is energized. Follow the steps

below to change the non-standard settings:

1. Pre ss Clear and Mode buttons. Hold at least 5 seconds

until the sensor enters the Edit mode.

2. Press Mode twice. The STDSET Menu will appear.

3. Use the Up/Down button to toggle to the NONSTD

menu and press Enter.

4. Use the Up/Down button to toggle through each of

the nine variables, starting with Altitude, until the

desired setting is reached.

5. Pre ss Mode to move through the var iables.

6. Press Enter to lock in the selection, then press Mode

to continue to the next variable.

Dehumidification of Fresh Air with DCV (Demand

Controlled Ventilation) Control

If normal rooftop heating and cooling operation is not

adequa te for the outdoor humidit y level, an energy

recove ry unit and/or a dehumidification option should be

considered.

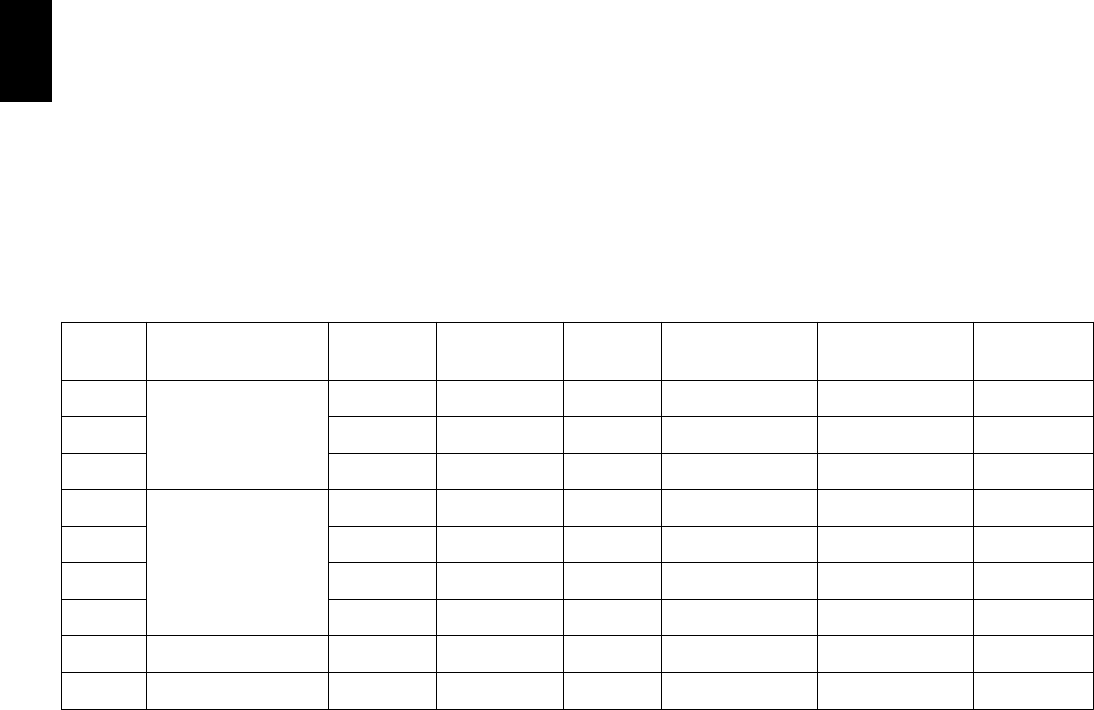

Table 23 – CO2 Sensor Standard Settings

SETTING EQUIPMENT OUTPUT

VENTILATION

RATE

(cfm/Person)

ANALOG

OUTPUT

CO

2

CONTROL RANGE

(ppm)

OPTIONAL

RELAY SETPOINT

(ppm)

RELAY

HYSTERESIS

(ppm)

1

Interface w/Standard

Building Control System

Proportional Any

0-10V

4-20 mA

0-2000 1000 50

2

Proportional Any

2-10V

7-20 mA

0-2000 1000 50

3

Exponential Any

0-10V

4-20 mA

0-2000 1100 50

4

Economizer

Proportional 15

0-10V

4-20 mA

0-1100 1100 50

5

Proportional 20

0-10V

4-20 mA

0- 900 900 50

6

Exponential 15

0-10V

4-20 mA

0-1100 1100 50

7

Exponential 20

0-10V

4-20 mA

0- 900 900 50

8

Health & Safety Proportional —

0-10V

4-20 mA

0-9999 5000 500

9

Parking/Air Intakes/

Loading Docks

Proportional —

0-10V

4-20 mA

0-2000 700 50

LEGEND: ppm— Parts Per Million

548J