6

Table 2 – Motor Test Volts

Unit Voltage Motor Voltage Min---Max Volts

208/230 230 190---250

460 230 210---250

575 460 420---500

5. Apply a jumper at unit cont rol terminals R to G to

initiate a demand for motor operation. Check for 24--v

output a t defrost board terminal IFO.

6. Check for proper control signal voltage at motor

signal leads VIO and BRN. Signal should be 22 to

28--v.

7. Disc onnect unit main power.

8. Reconnect motor power and control signal leads at

the motor terminals.

9. Restore unit main power.

Motor should start and run. If it does not, remove the

motor assembly. Replace with same motor part number;

do not substitute with an alternate design as torque/speed

programming will not be same as on original factory

motor.

Replacing the ECM Motor – Before removing the ECM

belly--band mounting ring, measure the dist ance between

the base of the motor shaft and the edge of the mounting

ring. Remove the motor mounting band a nd transfer to the

replacement motor. Position the mounting band at

distance measured in first step. Snug t he mounting bolt

but do not tighten yet.

Insert the m otor shaft into the fan wheel hub. Then secure

the three motor mount arms to the support cushions.

Torque t he arm mounti ng screws to 60 in--lbs (6.8 N--m).

Cente r the fan wheel in the fan housing. Torque the fan

wheel hub setscrew to 120 in--lbs (13.6 N--m).

Ensure the motor terminals are located at a position below

the 3 o’clock position (see Fig. 5). Tighten the motor

belly--band bolt to 80 in--lbs (9.0 N--m).

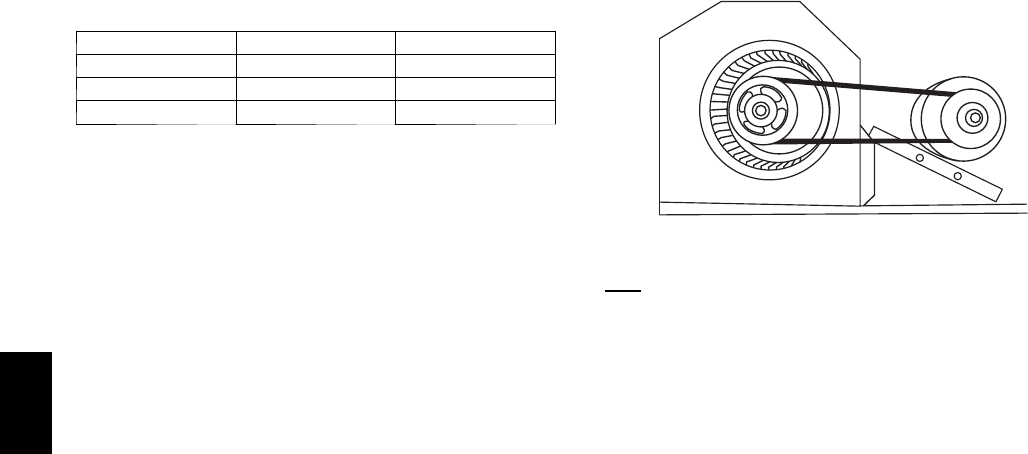

Supply Fan (Belt--Drive)

The belt--drive supply fan system consists of a

forward--curved c entrifugal blower wheel on a solid shaft

with two concentric type bearings, one on each side of the

blower housing. A fi xed--pitch driven pulley is attached to

the fan shaft and an adjustable--pitch driver pulley is on

the motor. The pulleys are connected using a “V” type

belt. (See Fig. 8.)

C07087

Fig. 8 -- Belt Drive Motor Mounting

Belt

Check the belt condition and tension quarterly. Inspect the

belt for signs of cracking, frayi ng or glazing along the

inside surfaces. Check belt tension by using a spring--force

tool (such as Browning’s Part Number “Belt Tension

Checke r” or equivalent tool); tension should be 6--lbs at a

5

/

8

--in. deflection when measured at the centerline of the

belt span. This point is at the center of the belt when

mea suring the distance between the motor shaft and the

blower shaft.

NOTE: Wit hout the spring--tension tool, place a straight

edge across the belt surface at t he pulleys, then deflect the

belt at mid--span using one finger to a

1

/

2

--in. deflection.

Adjust belt tension by loosening the motor mounting plate

front bolts and rear bolt and sliding t he plate toward the

fan (to reduce tension) or away from fan (to increase

tension). Ensure the blower shaft and the motor shaft are

parallel to each other (pulleys aligned). Tighten all bolts

when finished.

To replace the belt:

1. Use a belt with same section type or similar size. Do

not substitute a “FHP” type belt. When installing the

new belt, do not use a tool (screwdriver or pry--bar) to

force the belt over the pulley flanges, this wil l stress

the belt and cause a reduction in belt life.

2. Loosen the motor mounting plate front bolts and rear

bolts.

3. Push the motor and its mounting plate towards the

blower housing as close as possible to reduce the ce n-

ter distance between fan shaft and motor shaft.

4. Remove the belt by ge ntly lifting the old belt over

one of the pulleys.

5. Install the new belt by gently sliding the belt over

both pulleys and then sliding the motor and plate

away from the fan housing until proper tension is

achi eved.

6. Check th e a lignmen t of the pulleys, adjus t i f necess ary.

7. Tighten all bolts.

8. Check the tension after a few hours of runtime and

re--adjust as required.

548J