UNT-IOM-6 23

4. Vent the vacuum breaker line to atmosphere or connect it into the

return main at the discharge side of the steam trap.

5. Pitch all steam supply and return mains down a minimum of 1 inch

per 10 feet in the direction of flow.

6. Do not drain the steam mains or take-off through the coils. Drain

the mains ahead of the coils through a steam trap to the return line.

7. Overhead returns require 1 psig of pressure at the steam trap

discharge for each 2-foot elevation to ensure continuous condensate

removal.

8. Proper steam trap selection and installation is necessary for

satisfactory coil performance and service life. For installation, use the

following steps:

a. Locate the steam trap discharge at least 12 inches below the

condensate return connection. This provides sufficient hydrostatic

head pressure to overcome trap losses and ensure complete conden-

sate removal.

b. Trane Company recommends using flat and thermostatic traps

because of gravity drain and continuous discharge operation.

c. Use float and thermostatic

traps with atmospheric pressure

gravity condensate return, with

automatic controls or where the

possibility of low pressure supply

steam exists.

d. Always install strainers as

close as possible to the trap inlet

side.

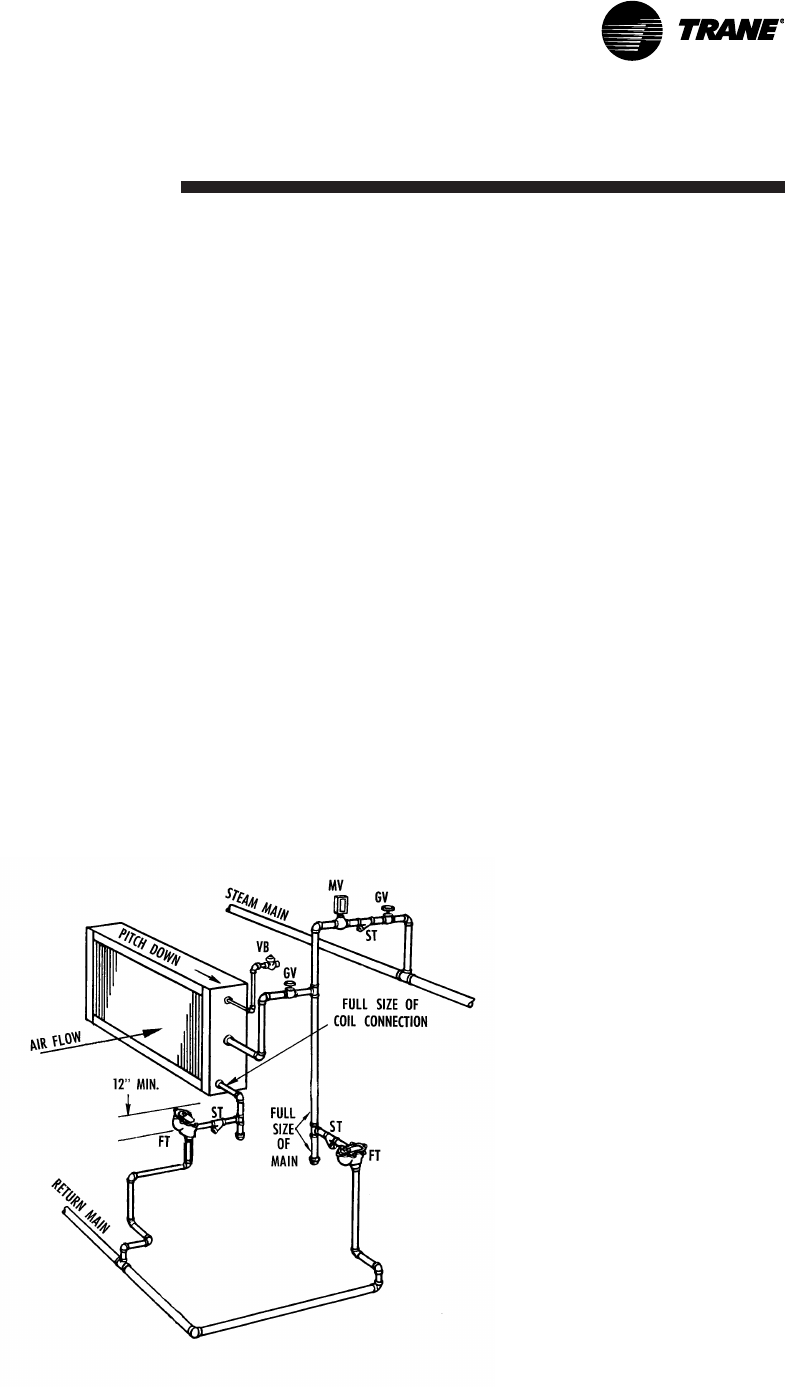

Reference Figure 8 for an ex-

ample of a properly piped steam

coil.

Figure 8. Example of typical piping to the steam coil.

ST = Strainer

FT = Float and

thermostatic

steam trap

MV = Manual

air vent

GV= Gate valve

VB = Vacuum

breaker, 15°

swing check

valve