13

Reference Manual

00809-0100-4860, Rev BC

Section 2: Installation

January 2013

Installation

2.5.5 Flanged-style flowmeter mounting

Physical mounting of a flanged-style flowmeter is similar to installing a typical section of pipe.

Conventional tools, equipment, and accessories (such as bolts and gaskets) are required.

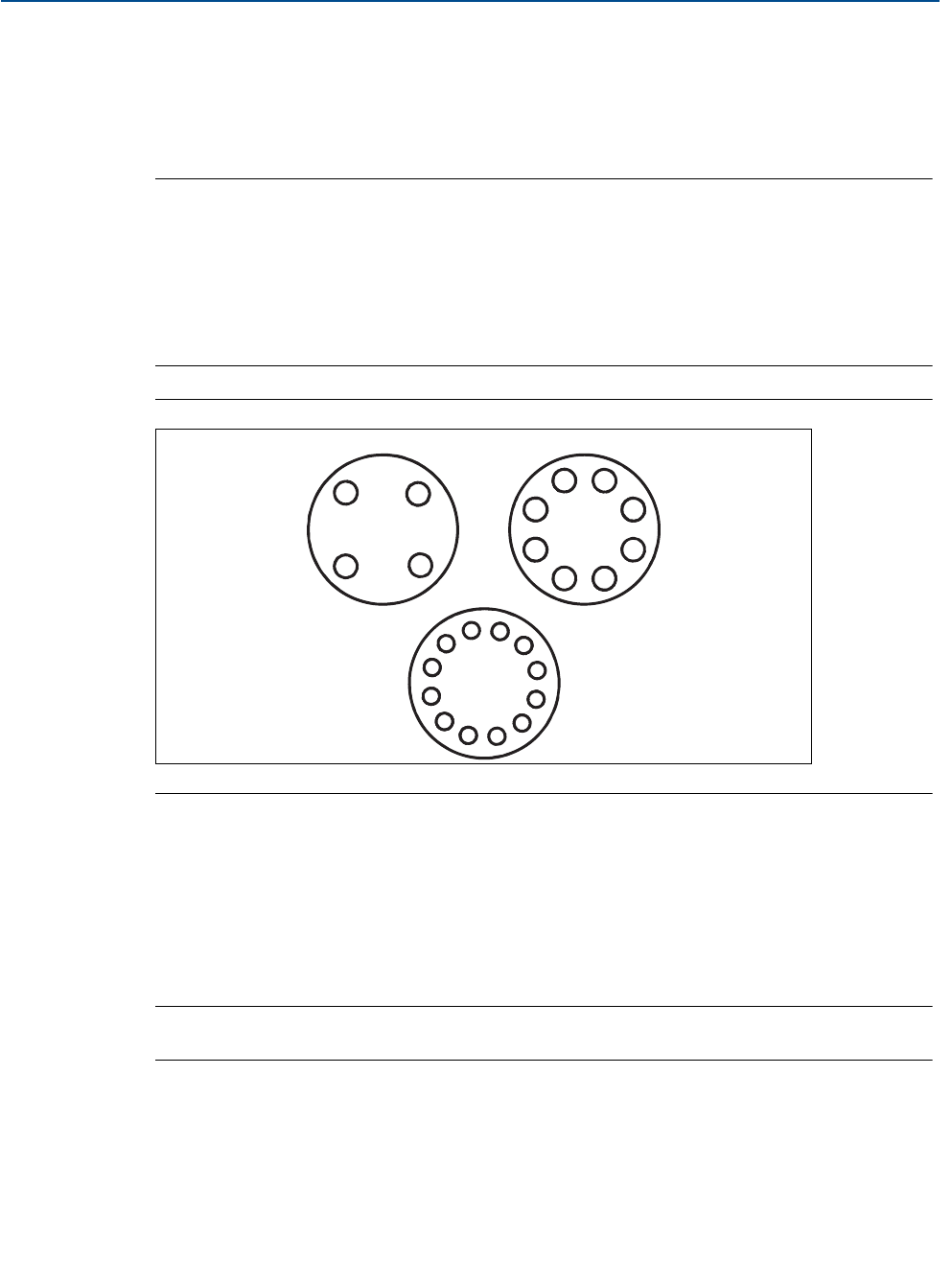

Tighten the nuts following the sequence shown in Figure 2-8.

Note

The required bolt load for sealing the gasket joint is affected by several factors, including operating

pressure and gasket material, width, and condition. A number of factors also affect the actual bolt

load resulting from a measured torque, including condition of bolt threads, friction between the nut

head and the flange, and parallelism of the flanges. Due to these application-dependent factors, the

required torque for each application may be different. Follow the guidelines outlined in the ASME

Pressure Vessel Code (Section VIII, Division 2) for proper bolt tightening. Make sure the flowmeter is

centered between flanges of the same nominal size as the flowmeter.

2.5.6 Flowmeter grounding

Grounding is not required in typical vortex applications; however, a proper ground will eliminate

possible noise pickup by the electronics. Grounding straps may be used to ensure that the

meter is grounded to the process piping. If you are using the transient protection option (T1),

grounding straps are required to provide a proper low impedance ground.

Note

Properly ground flow meter body and transmitter per the local code.

To use grounding straps, secure one end of the grounding strap to the bolt extending from the

side of the meter body and attach the other end of each grounding strap to a suitable ground.

Figure 2-8. Flange Bolt Torquing Sequence

1

3

4

2

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

10

11

12