7

Reference Manual

00809-0100-4860, Rev BC

Section 2: Installation

January 2013

Installation

Upstream/Downstream piping

The vortex meter may be installed with a minimum of ten diameters (D) of straight pipe length

upstream and five diameters (D) of straight pipe length downstream.

Rated accuracy is based on the number of pipe diameter from an upstream disturbance. No

K-factor correction is required if the meter is installed with 35 D upstream and 5 D downstream.

The value of the K-factor may shift up to 0.5% when the upstream straight pipe length is

between 10D and 35D. Please see Technical Data Sheet (00816-0100-3250) on Installation

Effects for optional K-factor corrections. This effect can be corrected for using the Installation

Effect Correction Factor (See page 52).

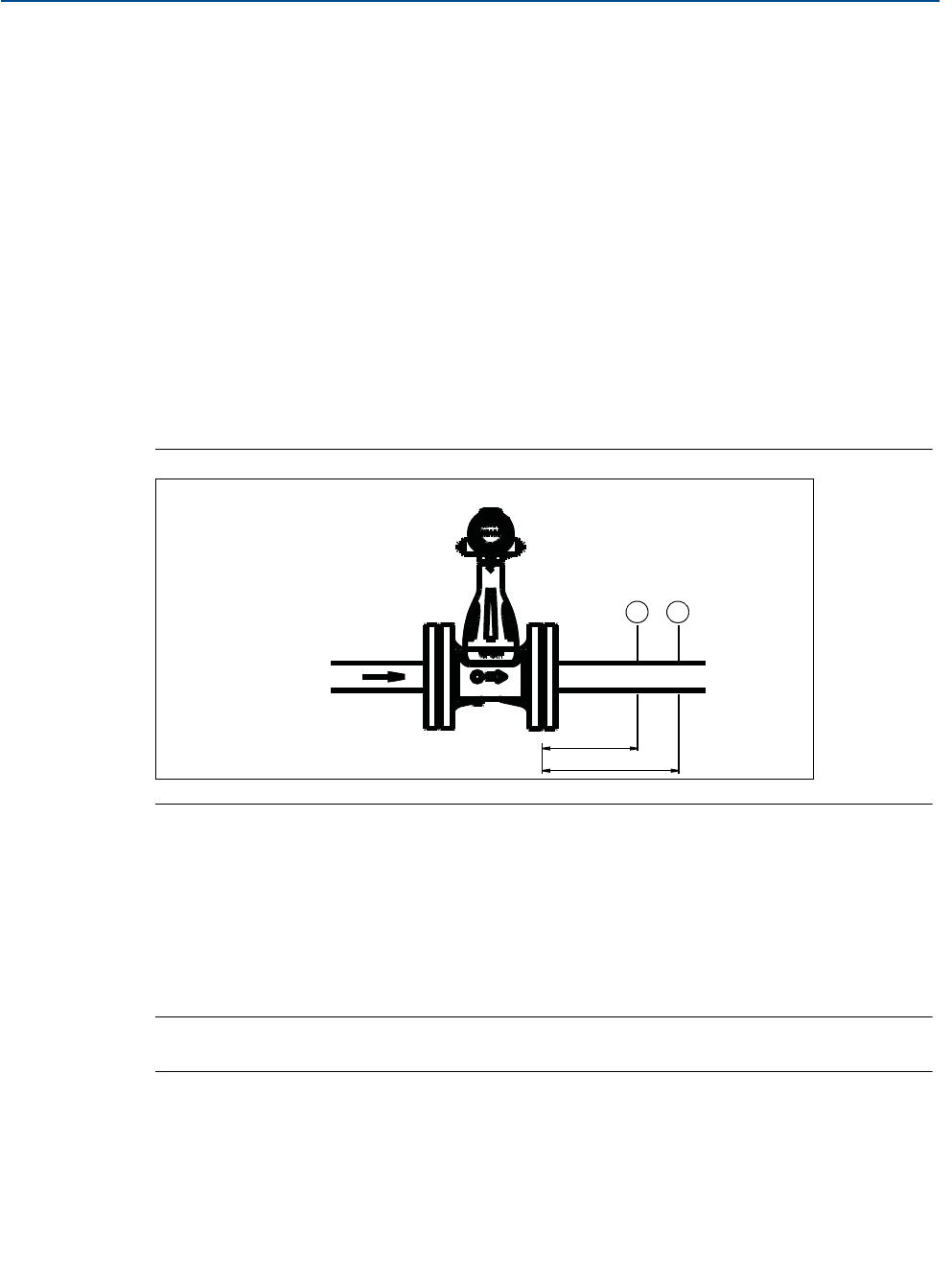

Pressure and temperature transmitter location

When using pressure and temperature transmitters in conjunction with the Rosemount 8600D

for compensated mass flows, install the transmitter(s) downstream of the Vortex Flowmeter.

See Figure 2-4.

2.2.4 Wetted material selection

Ensure that the process fluid is compatible with the meter body wetted materials when

specifying the Rosemount 8600D. Corrosion will shorten the life of the meter body. Consult

recognized sources of corrosion data or contact your Rosemount Sales Representative for more

information.

Note

For accurate results perform a Positive Material Identification (PMI) test on a machined surface.

2.2.5 Environmental considerations

Avoid excessive heat and vibration to ensure maximum flowmeter life. Typical problem areas

include high-vibration lines with integrally mounted electronics, warm-climate installations in

direct sunlight, and outdoor installations in cold climates.

Figure 2-4. Pressure and Temperature Transmitter Location

NOTE: The MTA option can be purchased for an integral

temperature measurement and mass flow temperature

compensation for saturated steam only.

4 Downstream

6 Downstream

TP