30 SCXG-SVX01B-EN

Water Piping

ƽƽ

ƽƽ

ƽ

WARNING

High Pressure Water!

Provide relief valves on system water

piping to prevent instantaneous release

of high pressure water. Failure to provide

relief valves could result in death or

serious injury or water pump damage or

unit failure.

Condenser Connections

Condenser water piping knockouts are in

the lower left end panel. If necessary,

remove insulation to gain access. All field

installed piping must conform to

applicable local, state, and federal codes.

To complete condenser water

connections follow the procedure below.

Note: Four condenser waterline drain plugs

ship in a bag in the unit’s left end. The

installer must field install these four plugs

using pipe thread sealer. An additional plug

is provided for units with a waterside

economizer.

1. Attach the water supply line to the inlet

connection, and the return line to the

outlet connection. Entering and leaving

water connections for all condensers

are factory manifolded and require only

single connections for entering and

leaving water. If the unit has a

waterside economizer and/or control

valves, the factory pipes between these

components.

2. If using a cooling tower, refer to Figure

I-MR-2 for a typical piping circuit from

the unit.

3. Ensure the water pressure to the unit

does not exceed 400 psig.

Note: To prevent water pump damage,

design system piping to provide relief

when using energy saving waterside

economizer valves.

Duct Connections

ƽƽ

ƽƽ

ƽ

WARNING

Hazardous Voltage w/Capaci-

tors!

Disconnect all electric power, including

remote disconnects before servicing.

Follow proper lockout/tagout proce-

dures to ensure the power cannot be

inadvertently energized. For variable

frequency drives or other energy storing

components provided by Trane or others,

refer to the appropriate manufacturer’s

literature for allowable waiting periods

for discharge of capacitors. Verify with an

appropriate voltmeter that all capacitors

have discharged. Failure to disconnect

power and discharge capacitors before

servicing could result in death or serious

injury.

Note: For additional information regard-

ing the safe discharge of capacitors, see

PROD-SVB06A-EN or PROD-SVB06A-FR.

Return air enters the rear of the unit and

conditioned supply air discharges through

the top. Attach supply air ductwork

directly to the unit’s top panel, around the

fan discharge opening. A duct collar is not

provided.

Note: Units equipped with the flexible

horizontal discharge plenum option may

include a duct collar when holes are factory

cut. If discharge openings are field-cut, refer

to the “Plenum Installation” section.

Install all air ducts according to the

National Fire Protection Association

standards for the “Installation of Air

Conditioning and Ventilation Systems

other than Residence Type (NFPA 90A)

and Residence Type Warm Air Heating

and Air Conditioning Systems (NFPA

90B).

Make duct connections to the unit with a

flexible material such as heavy canvas. If

a fire hazard exists, Trane recommends

using Flexweave 1000, type FW30 or

equivalent canvas. Use three inches for

the return duct and three inches for the

discharge duct. Keep the material loose to

absorb fan vibration.

Note: The compressors and fan assembly are

internally isolated. Therefore, external isolation

devices (spring mounting isolators) are at the

discretion of a vibration specialist consulted

by the building or HVAC system designer.

Run the ductwork straight from the

opening for a minimum of three fan

diameters. See Figure I-MR-1. Extend

remaining ductwork as far as possible

without changing size or direction. Do not

make abrupt turns or transitions near the

unit due to increased noise and excessive

static losses. Use elbows with splitters or

turning vanes to minimize static losses.

Poorly constructed turning vanes may

cause airflow generated noise. Align the

fan outlet properly with the ductwork to

decrease noise levels in the duct and to

increase fan performance. To complete

trunk ductwork to the VAV terminal units,

refer to the VAV box manuals for specific

requirements. Check total external static

pressures against fan characteristics to

be sure the required airflow is available

throughout the ductwork.

To achieve maximum acoustical perfor-

mance, minimize the duct static pressure

setpoint.

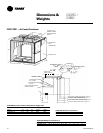

Figure I-MR-1. Duct connection recommenda-

tions

3 Fan

Diameters

Discharge

Duct

3-inch

Flexible

Duct

Return

Air

Mechanical

Specifications