175

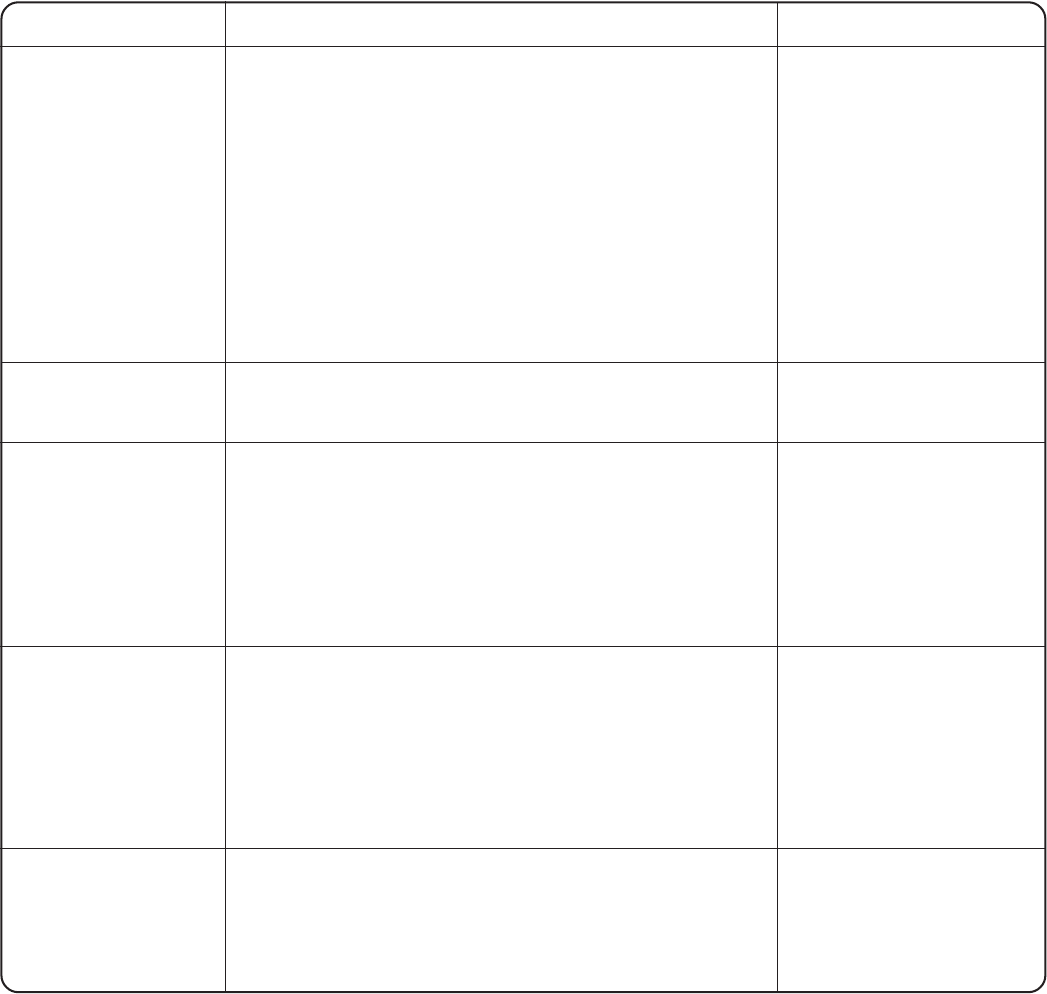

1. The needle tension is too tight.

2. The needle thread or the bobbin thread is not

threaded correctly.

3. The needle is too heavy for the fabric being sewn.

4. The stitch length is too long for the fabric.

5. The presser foot pressure is not adjusted correctly

*When sewing extremely lightweight materials place

interface underneath the fabric..

6. The fabric is not pulled tightly enough on the

embroidery hoop.

1. The presser foot pressure is not adjusted correctly

2. The correct presser foot is not being used.

1. The feed dog is packed with lint.

2. The presser foot pressure is too weak.

3. The stitches are too fine.

4. The fabric is not fed when sewing is starting.

5. The feed dog is lowered.

6. The correct presser foot is not used.

1. The machine is not plugged in.

2. A thread is caught in the hook race.

3. The control circuit is not working correctly.

4. The start/stop button is used for ordinary sewing

with foot control plugged in.

1. Something is caught between the carriage and the

arm.

2. The carriage is touching something around the

machine.

Seam puckering

Slipping fabric

The cloth is not

feeding

smoothly.

The machine does

not run.

Strange sounds

occur when the

machine is

switched on.

See page 41.

See pages 13, 14.

See page 19.

Make stitches denser

See page 24.

See page 121.

See page 24.

See page 22

See page 173.

See page 24.

Make stitches coarser.

See page 35.

See page 24.

Use the correct foot.

See page 7.

See page 173.

Turn the switch off

and turn it on again.

See page 8.

See page 122.

Remove the object.

See page 122.

Problem

Cause

Reference