Part number 550-142-054/0411

GV90+ gas-fired water boiler — Boiler Manual

74

Removing/cleaning/re-installing the recuperator

Disconnect the vent pipe from the recuperator

1. The vent pipe must be disconnected (at the in-line flue drain, item

A in Figure 7, page 9).

2. If the vent piping can be moved enough, loosen the flue pipe clamp

on the in-line flue drain. Then lift the flue pipe up and move aside

slightly.

3. If the vent piping cannot be moved, then cut the flue pipe carefully

so a coupling can be inserted later, or remove a section of vent pipe

if using stainless vent pipe.

Isolate boiler and drain partially

1. Remove the jacket top panel and front panel.

2. Allow time for the boiler to cool down if it has been operating.

3. Close the isolation valves on the boiler supply and return con-

nections.

4. The boiler will have to be partially drained.

a. Place a large pan under the boiler drain valve.

b. Slowly open the drain valve and allow about a gallon of water

to drain out.

c. Place the pan under the water connection flanges on the re-

cuperator.

d. Loosen the upper recuperator flange and allow any water in

the line to run out.

e. Loosen the lower recuperator flange (return connection) and

allow the water in the line and recuperator to drain out.

5. After the recuperator and water lines have been drained, disconnect

both recuperator flanges.

Remove the recuperator

1. See Figure 102, page 95. Loosen the (4) nuts that secure the recu-

perator to the boiler.

2. Carefully slide the recuperator off of the (4) studs.

3. Disconnect the plug-in connector on the thermal fuse (Fig-

ure 102, page 95, item 27).

4. Loosen the flue adapter clamp and remove the in-line drain fitting

from the flue adapter.

5. Dump any remaining water from the recuperator.

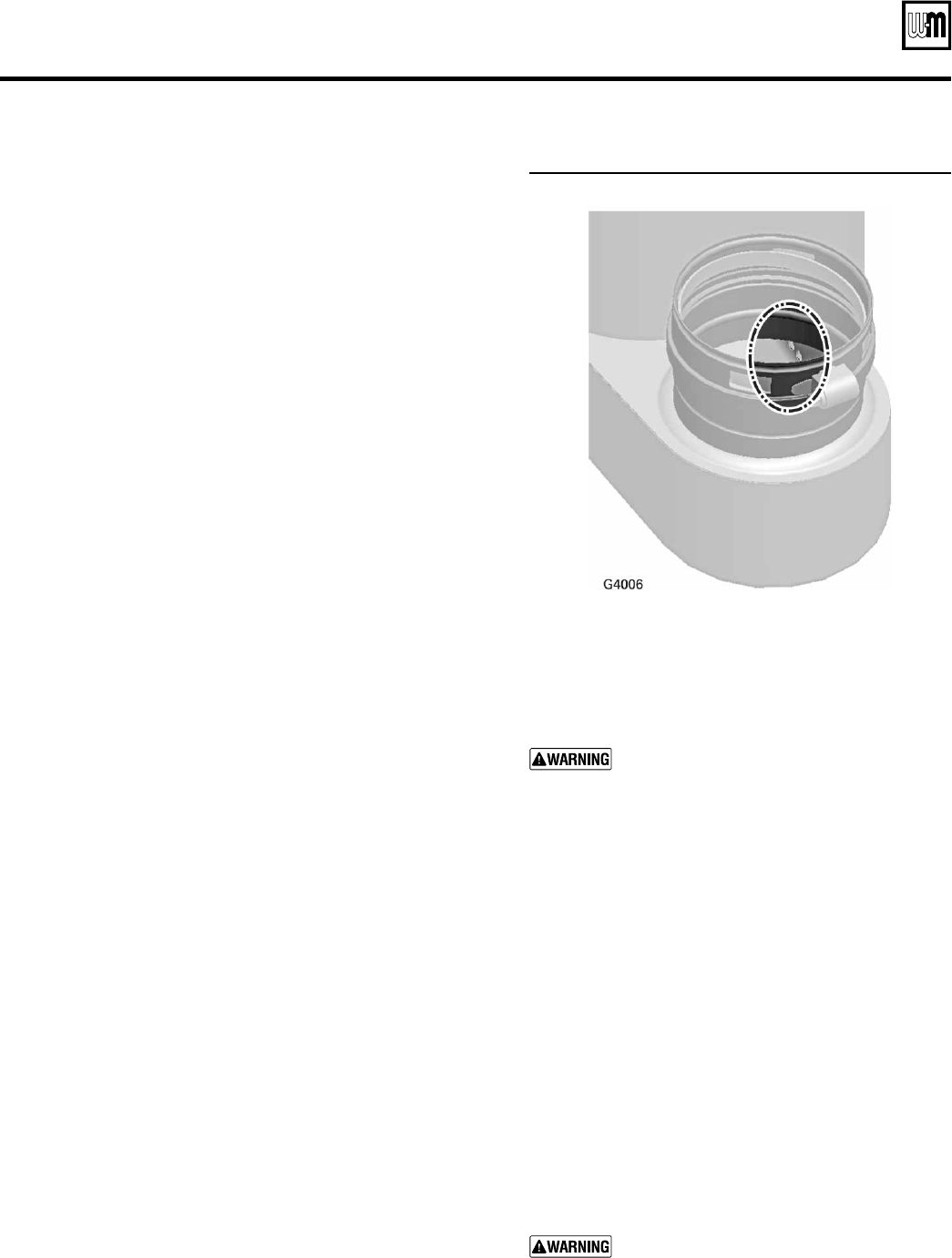

6. Look through the flue adapter and locate the flueway drain holes

as shown in Figure 84.

7. Use a brush or other means to remove blockage from these

holes.

8. Rinse the recuperator thoroughly.

Re-install the recuperator

1. Inspect the recuperator gaskets to make sure all are in good condi-

tion. Replace if there is any sign of damage.

2. Attach the recuperator at the boiler connection.

3. Secure with the four nuts.

4. Re-connect the water connections to the upper and lower recu-

perator flanges.

5. Re-insert the in-line drain fitting into the recuperator vent adapter.

Tighten the clamp to secure in place.

6. Re-connect the plug-in connector on the thermal fuse (Fig-

ure 102, page 95, item 27).

Figure 84 Recuperator flueway drain holes

Service & maintenance (continued)

Re-install the condensate trap and recuperator ac-

cess cover

1. Replace the condensate trap and recuperator access

cover — tighten bolts securely (do not exceed 18 inch-

pounds, 2 N-m, torque).

If the recuperator shows signs of significant

corrosion or deterioration, contact Weil-

McLain for recommendations on investigat-

ing the cause and replacing the recuperator if

necessary.

Make sure the recuperator access cover gasket

is in good condition. Replace if necessary.

Make sure the recuperator access cover and

the condensate trap are re-installed securely.

Failure to comply with the above could result

in severe personal injury, death or substantial

property damage.

Re-connect the vent pipe

1. If the vent pipe was lifted out, re-insert the vent pipe

into.

2. If the vent pipe was cut, install a coupling in the vent

line to allow re-connection.

3. If a section was removed (stainless vent pipe), replace

the section.

4. Re-connect the vent pipe to the in-line drain fitting and

tighten the clamp.

When replacing the vent pipe, follow all in-

structions in this manual to ensure the vent

is properly completed. Failure to properly the

vent pipe could result in severe personal in-

jury, death or substantial property damage.