Part number 550-142-054/0411

GV90+ gas-fired water boiler — Boiler Manual

30

Venting & air — general (continued)

Provide combustion air:

DIRECT VENT — The installation must provide com-

bustion air piping. In addition, ventilation openings

may be required.

DIRECT EXHAUST — The installation must provide

combustion air openings to the boiler space.

ALL APPLICATIONS — The installation must provide

combustion air openings as needed for other appli-

ances in the space.

Vent and air termination options

1. Vent and air piping must terminate out the sidewall or through the

roof of the building, using only one of the methods described in this

manual. See Figure 39, page 32 and Figure 40, page 33 for allowable

configurations and piping materials.

DIRECT VENT installations

1. For direct venting, combustion air must be piped from outside to the

boiler, following the instructions in this manual, and compliant with

all applicable codes.

2. Ventilation openings are required for some spaces. See Fig-

ure 42, page 36.

3. If other appliances are located in the same space with the GV90+ boiler,

provide openings shown in Figure 42, page 36.

If combustion and ventilation air openings are not provided

as directed above and the room does not have adequate

ventilation, the higher temperature in the space may result

in reduced component life.

DIRECT EXHAUST installations

1. Combustion and ventilation air must be provided in the boiler room

on direct exhaust installations. Follow all instructions in this manual

(see page 49 for air opening instructions) and all applicable codes to

provide required air openings.

DO NOT sidewall vent DIRECT EXHAUST APPLICATIONS

at altitudes above 5,500 feet. Sidewall venting is only allowed

for DIRECT VENT applications (ducted combustion air) at

altitudes above 5,500 feet.

Combustion air contamination:

Ensure that the combustion air will

not contain any of the contaminants

in Figure 36

.

DO NOT place combustion air supply

openings or intake terminations near

a swimming pool, for example.

Avoid areas subject to exhaust fumes

from laundry facilities. These areas will

always contain contaminants.

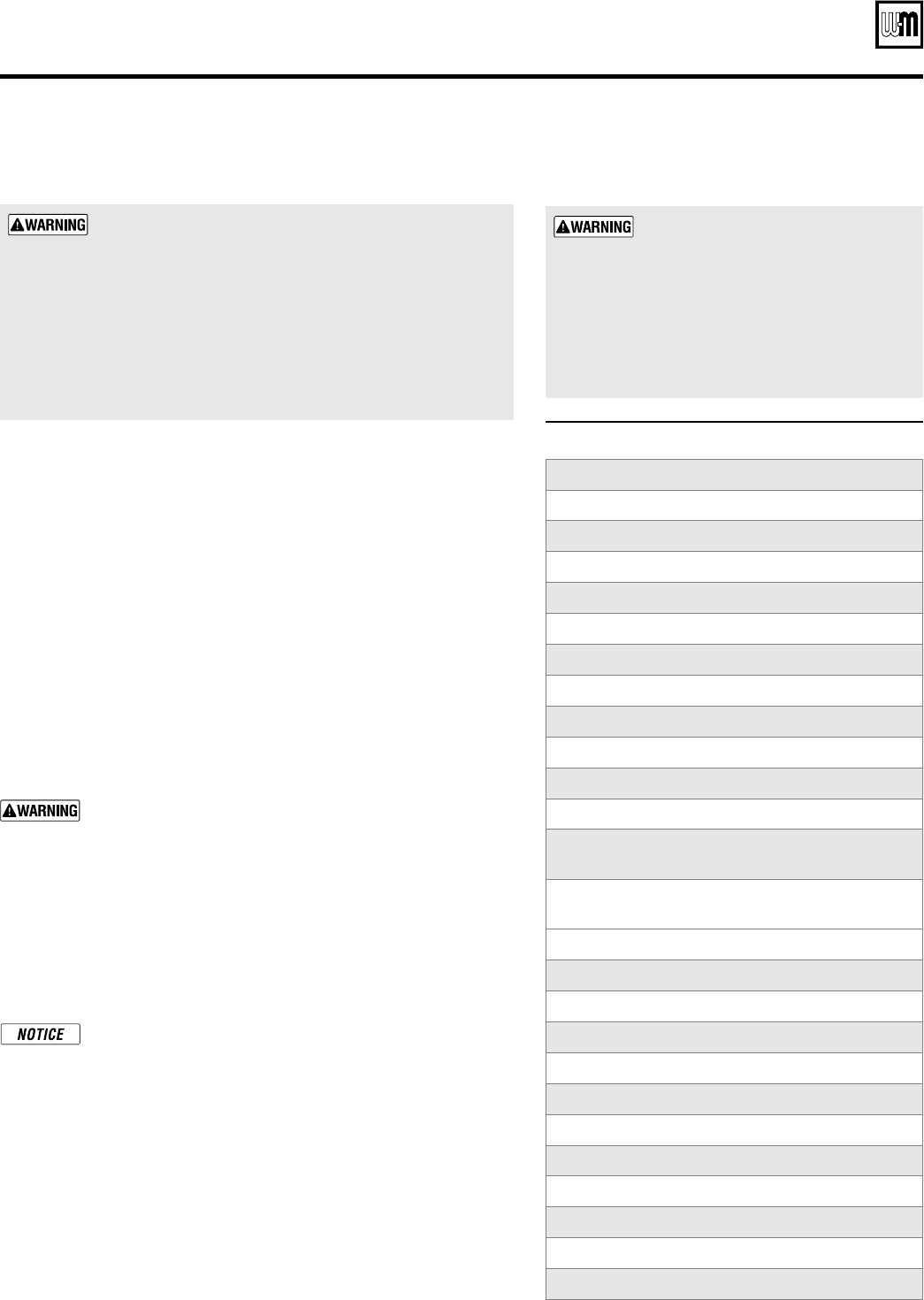

Figure 36

Corrosive contaminants and sources

Products to avoid

Spray cans containing chloro/fluorocarbons

Permanent wave solutions

Chlorinated waxes/cleaners

Chlorine-based swimming pool chemicals

Calcium chloride used for thawing

Sodium chloride used for water softening

Refrigerant leaks

Paint or varnish removers

Hydrochloric acid/muriatic acid

Cements and glues

Antistatic fabric softeners used in clothes dryers

Chlorine-type bleaches, detergents, and cleaning

solvents found in household laundry rooms

Adhesives used to fasten building products and

other similar products

Excessive dust and dirt

Areas likely to have contaminants

Dry cleaning/laundry areas and establishments

Swimming pools

Metal fabrication plants

Beauty shops

Refrigeration repair shops

Photo processing plants

Auto body shops

Plastic manufacturing plants

Furniture refinishing areas and establishments

New building construction