Part number 550-142-054/0411

45

GV90+ gas-fired water boiler — Boiler Manual

DIRECT VENT — Vertical with 3” concentric

Allowable vent/air pipe materials &

lengths

1. The 3” concentric termination kit must be pur-

chased separately.

Use only the vent materials and kits listed

in Figure 40, page 33. Provide pipe adapt-

ers if specified.

2. Locate the termination such that the total air piping

and vent piping from the boiler to the termina-

tion will not exceed the maximum length given in

Figure 39, page 32.

3. This termination requires a 45-degree elbow that

is not supplied with the termination kit. The

maximum vent/air pipe lengths include allowance

for this elbow.

Determine termination location

Locate the concentric vent/air termination using the

following guidelines:

1. The concentric vent/air assembly must terminate

as shown in Figure 56, page 46.

2. The termination must comply with the clearances

and limitations shown in Figure 41, page 35.

3. Locate the termination so it is not likely to be dam-

aged by foreign objects, such as stones or balls, or

subject to buildup of leaves or sediment.

4. For Canadian installations, follow requirements of

CSA B149.1 or B149.2 Installation Code.

Multiple vent/air terminations

1. When terminating multiple GV90+ boilers, install

the concentric vent/air termination assemblies as

described in this manual.

All vent outlets must terminate at the

same height to avoid possibility of severe

personal injury, death or substantial

property damage.

2. Place roof penetrations to obtain minimum of

12 inches between centers of adjacent vent pipe

of another boiler for U. S. installations (see Fig-

ure 56, page 46).

3. The air inlet of a GV90+ boiler is part of a direct

vent connection. It is not classified as a forced air

intake with regard to spacing from adjacent boiler

vents.

Prepare roof penetrations

1. Roof penetration hole:

a. Cut a 5-inch diameter hole to clear the 4½-inch

termination outside diameter.

b. Insert a galvanized metal thimble in the vent

pipe hole.

2. Follow all local codes for isolation of vent pipe when

passing through floors, ceilings and roofs.

3. Provide flashing and sealing boots sized for the

concentric termination outside diameter.

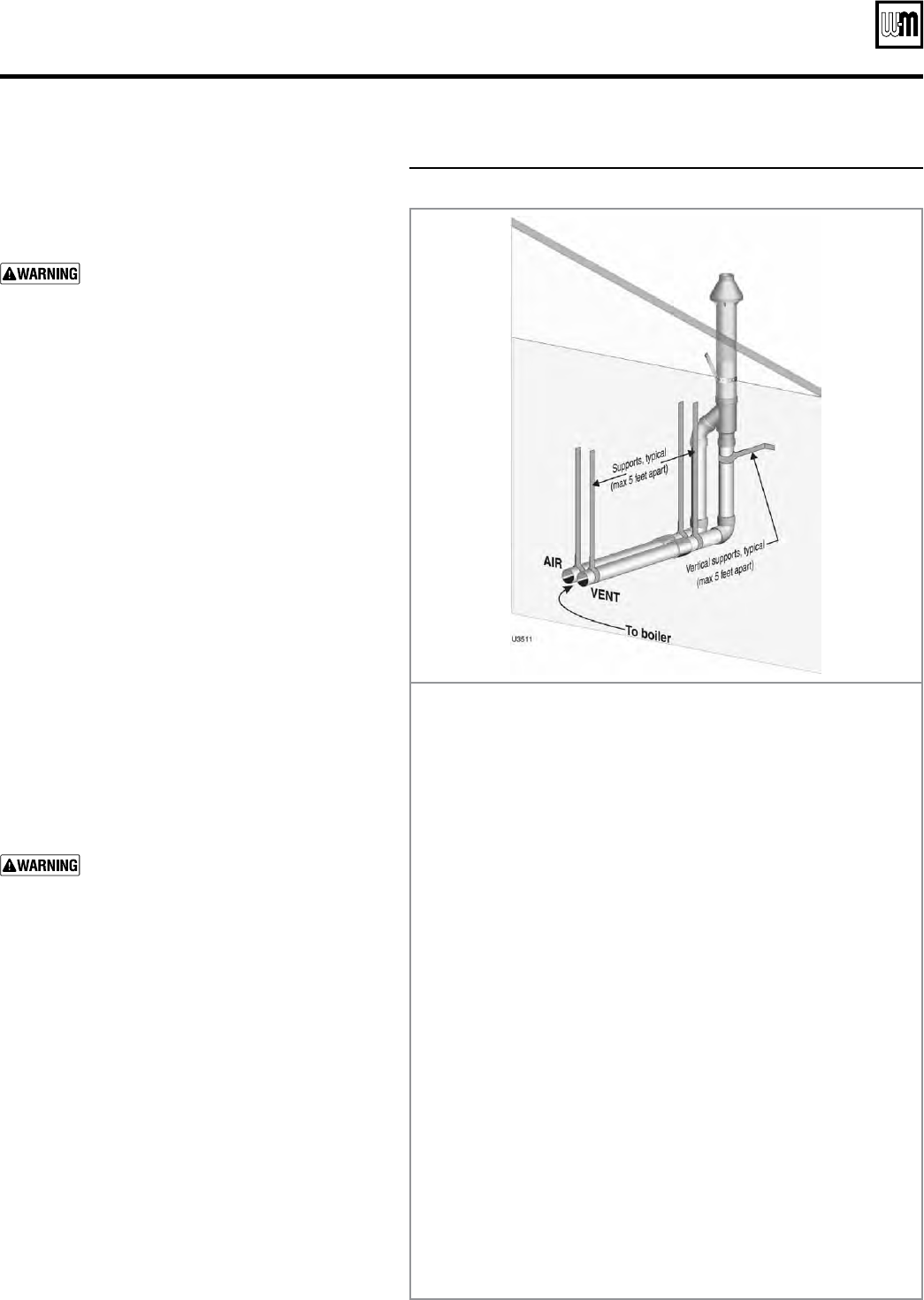

Figure 55 INSTALLATION SEQUENCE — Concentric vertical

Step 1 Read and follow all instructions in this manual. DO NOT

proceed with vent/air installation until you have read

page 29 through page 35.

Step 2

Install the boiler in a location that allows proper routing of

all vent and air piping to the selected sidewall location.

Step 3 Make sure the selected vertical termination location com-

plies with Figure 41, page 35. (Multiple boiler concentric

terminations must also comply with Figure 56, page 46.)

Step 4 Use only the vent materials listed in Figure 40, page 33.

Provide pipe adapters where required.

Step 5 Vent piping and air piping lengths must not exceed the

values shown in Figure 39, page 32.

Step 6 The concentric termination must be assembled and installed

before piping from the boiler to the termination.

Step 7 Prepare the vertical penetration(s) — assemble the concen-

tric termination kit and secure the penetration components

as instructed in this section. Provide the supports indicated

and mount the termination assembly. See “Prepare roof

penetrations” on page 45 and “Mount concentric termina-

tion” on page 46.

Step 8 Install vent and air piping between the boiler and the

concentric vent/air termination. Slope horizontal piping

downward toward the boiler at least 1/4 inch per foot. See

page 48 for general guidelines.

Step 9 Install pipe supports every 5 feet on both the horizontal and

vertical runs.

Step 10 Install a hanger support within 6 inches of any upturn in

the piping.