8

XPAK 85

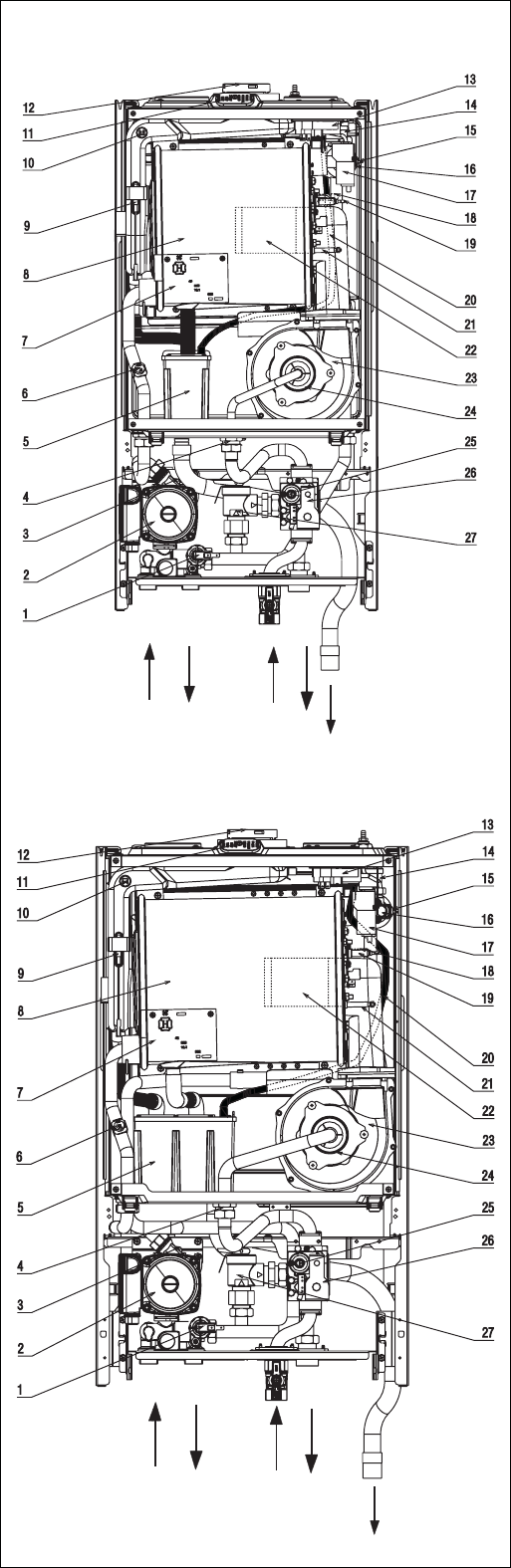

Fig. 1

GF

R

P

C

5 - INTRODUCTION

The XPak boiler is a wall hung, fan assisted, direct vent, heating

boiler only. These boilers – by design – incorporate electronic

ignition, circulating pump, pressure relief valve, pressure gauge,

and automatic bypass.

As supplied, the boiler will automatically modulate to provide

central heating outputs between 25,600 - 87,000 Btu/hr (7.5-25.5

kW) - XPak 85 and 27,300 - 119,500 Btu/hr (8-35 kW) XPak 120.

IMPORTANT

It is the law that all gas appliances are installed by a competent

person.

It is in your own interest and that of safety to ensure that the law is

complied with.

• The installation must conform to the requirements of the authority

having jurisdiction or, in the absence of such requirements, to

the National Fuel Gas Code, ANSI Z223.1/NFPA 54 Where

required by the authority having jurisdiction, the installation must

conform to the Standard for Controls and Safety Devices for

Automatically Fired Boilers, ANSI/ASME CSD-1.

• The installation should conform with CGA B149 INSTALLATION

CODE and/or local installation Code, plumbing or waste water

codes and other codes as applicable.

• Clearances from combustible material must be strictly adhered to.

• Manufacturers instructions must NOT be interpreted in anyway

as overriding statutory obligations.

The XPak family comprises a range of high-efficiency hot water

boilers with outputs ranging from 87,000 Btu/hr (25.5 kW) to

119,500 Btu/hr (35 kW). Each appliance is provided with a fan

powered flue outlet with an annular co-axial combustion air intake

that can be rotated – horizontally – through 360 degrees for

various horizontal or vertical applications. The XPak can also be

used with two pipe flue vent system. These appliances are

designed for use with a sealed system only; consequently they

are not intended for use on open vented systems.

This booklet is an integral part of the appliance. It is therefore

necessary to ensure that the booklet is handed to the person

responsible for the property in which the appliance is located/

installed. A replacement copy can be obtained from Raypak

customer services.

General layout (Fig. 1)

1 Water pressure switch

2 Pump

3 Bottom auto air vent (AAV)

4 Gas injector

5 Condense trap

6 Return sensor

7 H stamp main heat exchanger

8 Main heat exchanger

9 Flue thermostat

10 Flue sensor

11 Flue gas analysis test point

12 Flue outlet & air intake

13 Blocked flue switch

14 Top automatic air vent

15 Flow sensor

16 High limit thermostat

17 Ignition transformer

18 Sensing Electrode

19 Spark Electrode

20 Top automatic air vent drain pipe

21 Condensate level sensor

22 Cylindric Burner

23 Fan assembly

24 Mixer

25 Gas modulator coil

26 Gas valve

27 Pressure relief valve

R Boiler IN connection

F Boiler OUT connection

G Gas connection

P Pressure relief valve drain

C Condensate drain pipe

XPAK 120

G

F

R

P

C