25

2. BOILER SUPPLY

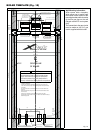

XPak boilers are supplied with the following vent components and they

are certified together with the XPak boiler as a constructional unit.

- 60/100 mm vent exit (Fig. 16 pos. 1)

- Left side intake air (factory sealed with two screws) for two pipes

solutions (Fig. 16 pos. 2)

- Right side intake air (factory sealed with two screws) for two

pipes solutions (Fig. 16 pos. 3)

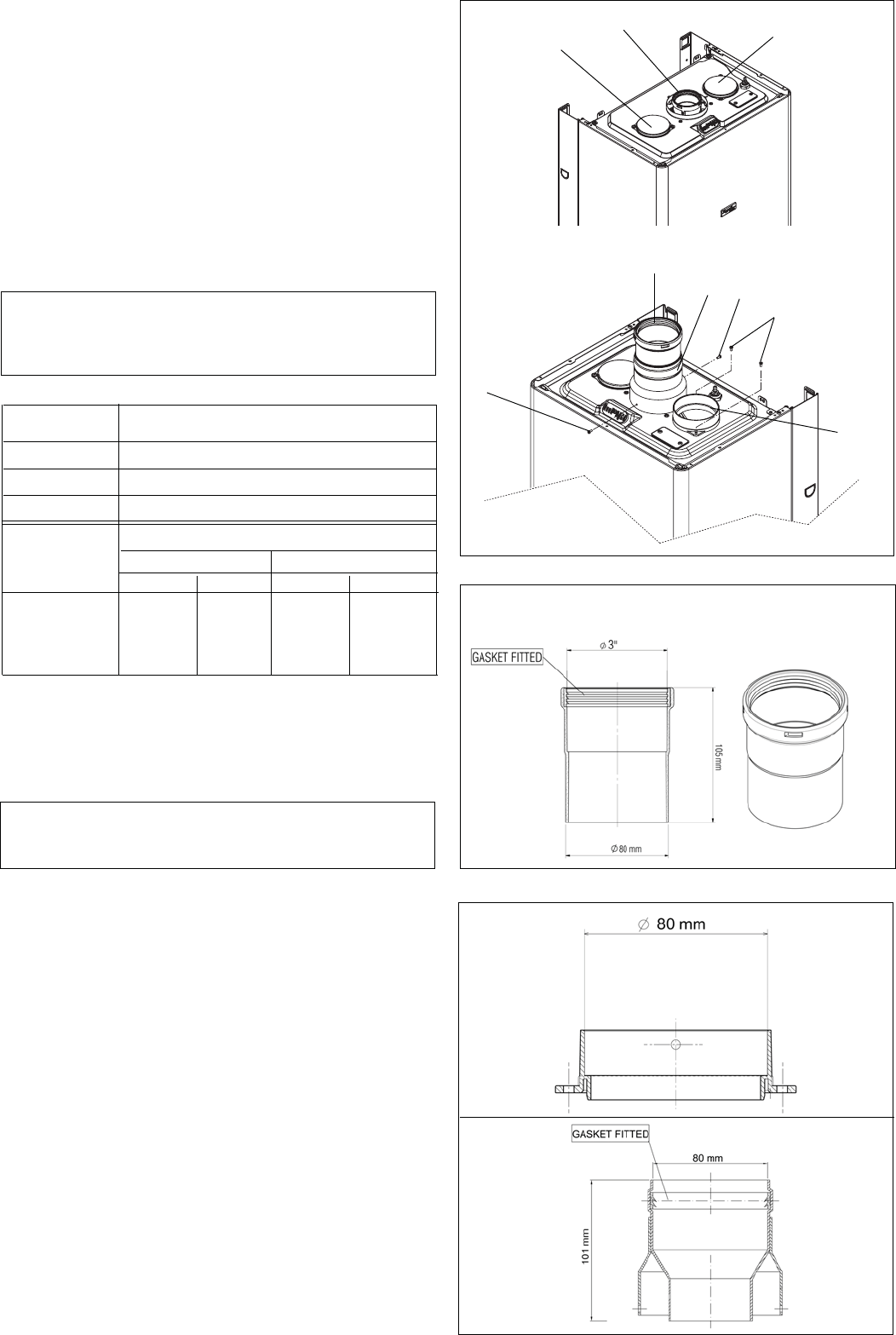

- Vent adaptor for two pipes vent system – 80 mm dia exit (Fig. 16

pos. 5) (Fig. 19)

- Intake air adaptor for two pipes vent system – 80 mm dia exit (Fig.

16 pos. 6) (Fig. 18)

- 3” adaptor (inside diameter 3”) (Fig. 16 pos 4, Fig. 17)

- Paper template to fix the boiler and the flues (Fig. 15)

Fig. 16

3. INSTALLATIONS OF SUPPLIED VENT COMPONENTS

In the case of installations using two pipes or room dependent air

the following instructions must be observed.

1. Install the vent adapter (Fig. 19) to the boiler vent connection

(Fig. 16 pos. 1)

2. Use the two supplied screws to ensure the closing between

the adapter and boiler (Fig. 16 pos. 5)

3. Insert the 3” adapter (Fig. 17) into the vent adapter (Fig. 19) in

the case using 3” vents

4. Install the air adapter (Fig. 18) to the boiler air connection (choose

right or left installation (Fig. 16 pos. 2 - 3), using the two supplied

screws (Fig. 16 pos. 6) in the case of two pipes, room sealed vent

installation.

Fig. 19

Fig. 17

Fig. 18

VENT SYSTEMS

1. FLUE GAS SYSTEM

Raypak coaxial PP (Polypropylene/Aluminium) concentric flue

gas/fresh air systems, Raypak coaxial Alu/Alu concentric flue

gas/fresh air systems and two-pipe aluminum systems for room

air independent operation (sealed combustion) and air

dependent operation and side wall venting are tested to ANSI

ANSI Z21.13b 2007 – CSA 4.9b 2007 standards and are certified

together with the XPak boiler as a constructional unit.

The XPak boiler may also be vented vertically or horizontally,

using a metallic AL29-4C

®

special stainless steel - Suggested

sources: ProTech System Inc., or room air dependent venting

system (UL/ULC listed for category IV).

For a more detailed description of the direct vent and single-wall

vent system, please refer to the following installation Instructions.

Always follow XPak Installation Instructions.

Select vent material based on

- Country of the installation

- Vent configuration

- Preferred material

- Necessary maximum equivalent length

FasNseal

stainless steel vent

Country US + CANADA

Diameter 3”

Material Stainless steel

Single wall Maximum Equivalent Length 3” (80 mm)

Tab. 5

NOTICE:

Brick or masonry surfaces directly behind the horizontal vent

termination should be protected with a rust-resistant sheet

metal plate.

NOTICE:

The minimum covering wall thickness is 1” (25 mm)

The maximum covering wall thickness is 16” (406 mm)

4

5

6

A

B

A

1

2

3

1 Gasket in EPDM (peroxide) -58°F (-50°C) – 302°F (150°C)

2 Adapter in PP (polypropylene) male/female 80 mm > 3”

De-rate less 5%De-rate less 2%

XPak 85

XPak 120 XPak 85 XPak 120

Horizontally/

vertically

vented

(air+flues)

40+40ft

16+16

130+130 115+115

12+12m

5+5

40+40 35+35