56

13 - LPG INSTRUCTIONS

LPG INSTRUCTIONS

PROPANE GAS:

CAUTION: The gas supply shall be shut off prior to

disconnecting the electrical power, before proceding with the

conversion.

Installation Codes

Installations must follow these codes:

• Local, state, provincial, and national codes, laws, regulations

and ordinances

• National Fuel Gas Code, ANSI Z223.1/NFPA 54 – latest edition

(NFGC)

• For Canada only: CAN/CSA B149 Natural Gas and Propane

Installation Code and CSA C22.1 C.E.C. Part 1 (C22.1)

WARNING: XPak boilers are shipped ready to fire natural gas

ONLY. You must install the propane orifice and regulate the

gas valve if the boiler will be connected to propane. Failure to

comply could result in severe personal injury, death or

substantial property damage.

Pipe sizing for natural gas

Contact gas supplier to size pipes, tanks and 100% lockup gas

pressure regulator.

Propane supply pressure requirements

1. Adjust propane supply regulator provided by gas supplier for

13" w.c. maximum pressure.

2. Pressure required at gas valve inlet pressure port: Maximum:

13" w.c. with no flow (lockup) or 8" w.c. minimum with boiler

operating

WARNING: This conversion kit shall

be installed by a qualified service

agency in accordance with the

manufacturer’s instructions and all

applicable codes and requirements

of the authority having jurisdiction.

If the information in this instructions

is not followed exactly, a fire, an

explosion or production of carbon

monoxide may result causing

property damage, personal injury

or loss of life. The qualified service

agency is responsible for the proper

installation of this kit. The installation

is not proper and complete until the

operation of the converted appliance

is checked as specified in the

manufacturer’s instructions

supplied with the kit.

This instruction must be retained adjacent

to the boiler as they contain important

details about the conversion made.

The XPak boiler is factory supplied to use natural gas. The boiler can

use also LPG gas by installing a kit (supplied with every unit). The

conversion to LPG is possible by:

1. Install the new gas injector

2. Modify the fan speed according the data in the table.

The kit is composed by:

1. Injector black coating (to be recognized from the natural gas

that is not black coated)

2. Relative gas sticker (red color) to be attached under the boiler

instead of the natural gas sticker (yellow color factory installed)

3. Instruction of the kit

4. LPG label to be affixed on the boiler casing and completed in

by the organization making this conversion.

Operations for conversion

1. Switch off the boiler

2. Change the gas injector

3. Apply the red sticker

4. Switch on the boiler

5. Set the new fan speed

6. Fill the final part of this instruction

GAS SUPPLY

The gas supply must be connected to the boiler by a competent LPG

installer and must be of sufficient size to supply the boiler at its

maximum output. An existing supply must be checked to ensure that

it is of adequate size to deal with the maximum rated input of this and

any other appliances that it serves.

GAS SUPPLY INSTALLATION

The entire installation including the meter must be purged and

checked for gas tightness.

CONVERTING THE BOILER GAS TYPE

To convert the boiler to another gas type it is necessary to change

the gas injector, adjust the fan speed and the gas valve.

NOTICE: The gas valve sticker “WARNING: VALVE IS NOT FIELD

SERVICEABLE” means the valve can be adjusted but not disassembled.

Fig. 1

CHANGE THE GAS INJECTOR

Slacken and unscrew upper gas

valve pipe; locate and remove the

two screws shown as (A). Locate

and remove the natural gas injector

(B) inside the pipe, insert the LPG

injector (black coating). Replace in

the reverse order. Check and

adjust burner pressure settings.

WARNING:

A gas tightness check must be

carried out if any gas carryng

components have been removed,

replaced or disturbed.

B

A

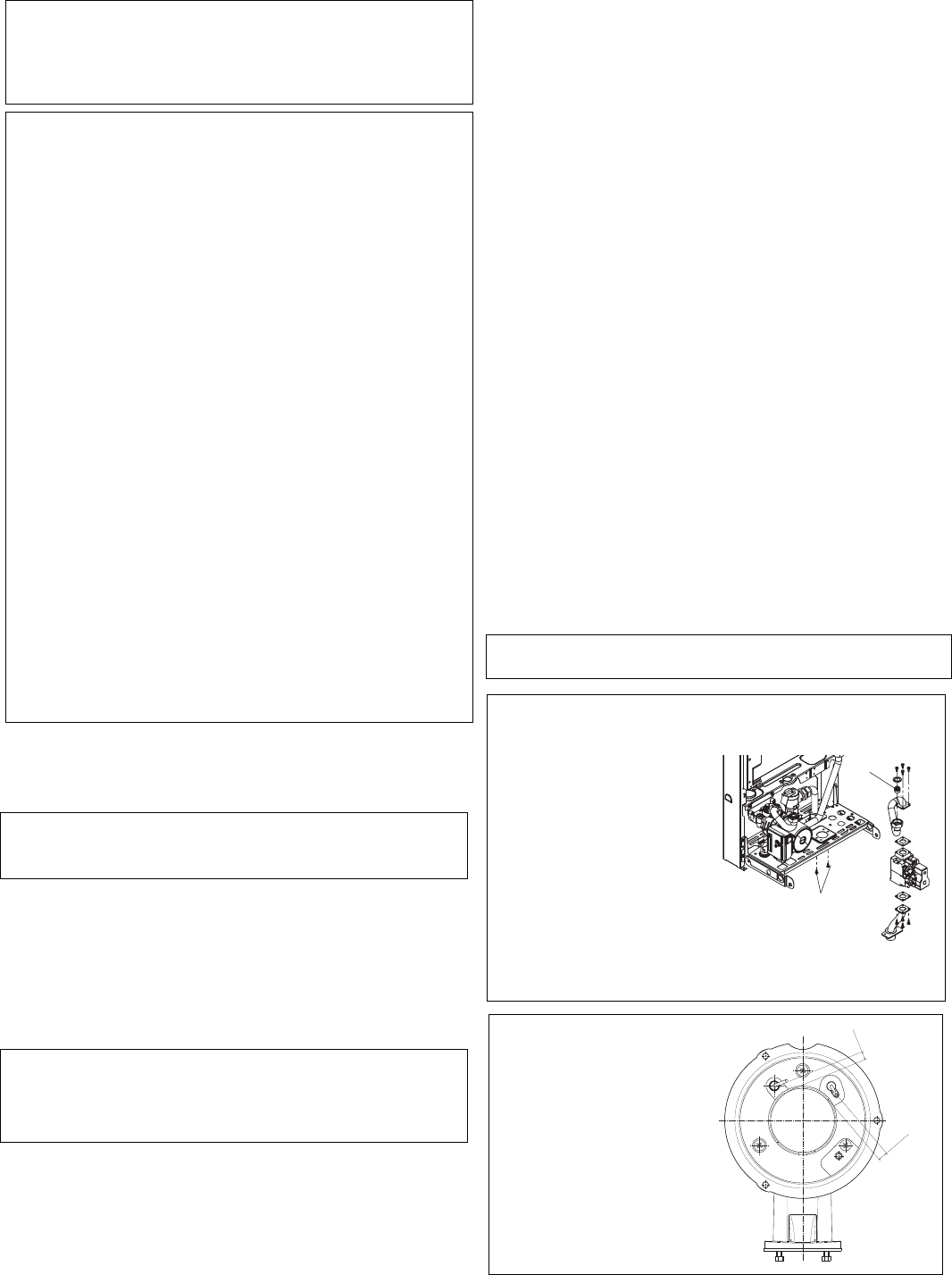

CHECKING THE

RELATIONSHIP OF THE

IGNITER TO MAIN BURNER

Remove the burner assembly as

indicated in the boiler manual

“Servicing instructions”.

Check the distance between the

burner and the two electrodes

according the distances

indicated in Fig. 1A. Replace in

the reverse order.

Fig. 1A

0.35”±0.039”

(8.9 mm ± 1)

0.41”±0.039”

(10.3 mm ± 1)