43

10 - START-UP AND OPERATION

XPak wall-mounted condensing boiler is designed for the

production of heating and domestic hot water if a storage tank is

connected.

The control panel contains the main boiler control and manage-

ment functions.

1. SWITCHING ON THE APPLIANCE

Switch on the boiler as follows:

- Open the gas tap under the boiler by turning it

counterclockwise (Fig. 46)

- Turn on the general switch of the system and then, after

lowering the flap, turn the function selector to summer

,

winter

or winter tank temperature

F

(Fig. 54) depending

on the chosen operating mode.

Pump cycle mode

: when power is restored to the boiler and/

or the boiler is powered for the first time, the boiler will enter a 2-

minute purge cycle whereby only the pump will run for 15-seconds

then off for 15-seconds and will not “fire” until this period has

elapsed. To interrupt the purge cycling remove the knob of the

main selector switch and press the CO button (Fig. 59).

Off/reset

- Select this position when the boiler needs to be

reset or switched off.

Summer mode

- The domestic hot water function provided

by the water tank is activated. The display indicates the storage

tank temperature (only with the external water tank connected

with a sensor).

Winter mode

- The boiler produces hot water for heating

and, if connected to an external water tank, it provides domestic

hot w

ater. The display indicates the boiler flow temperature.

Winter mode tank temperature

F

- The boiler produces

hot water for heating and, if connected to an external water tank

with a sensor

, it provides domestic hot water. The display indicates

the storage tank temperature.

2. HOW TO READ THE DISPLAY TEMPERATURE

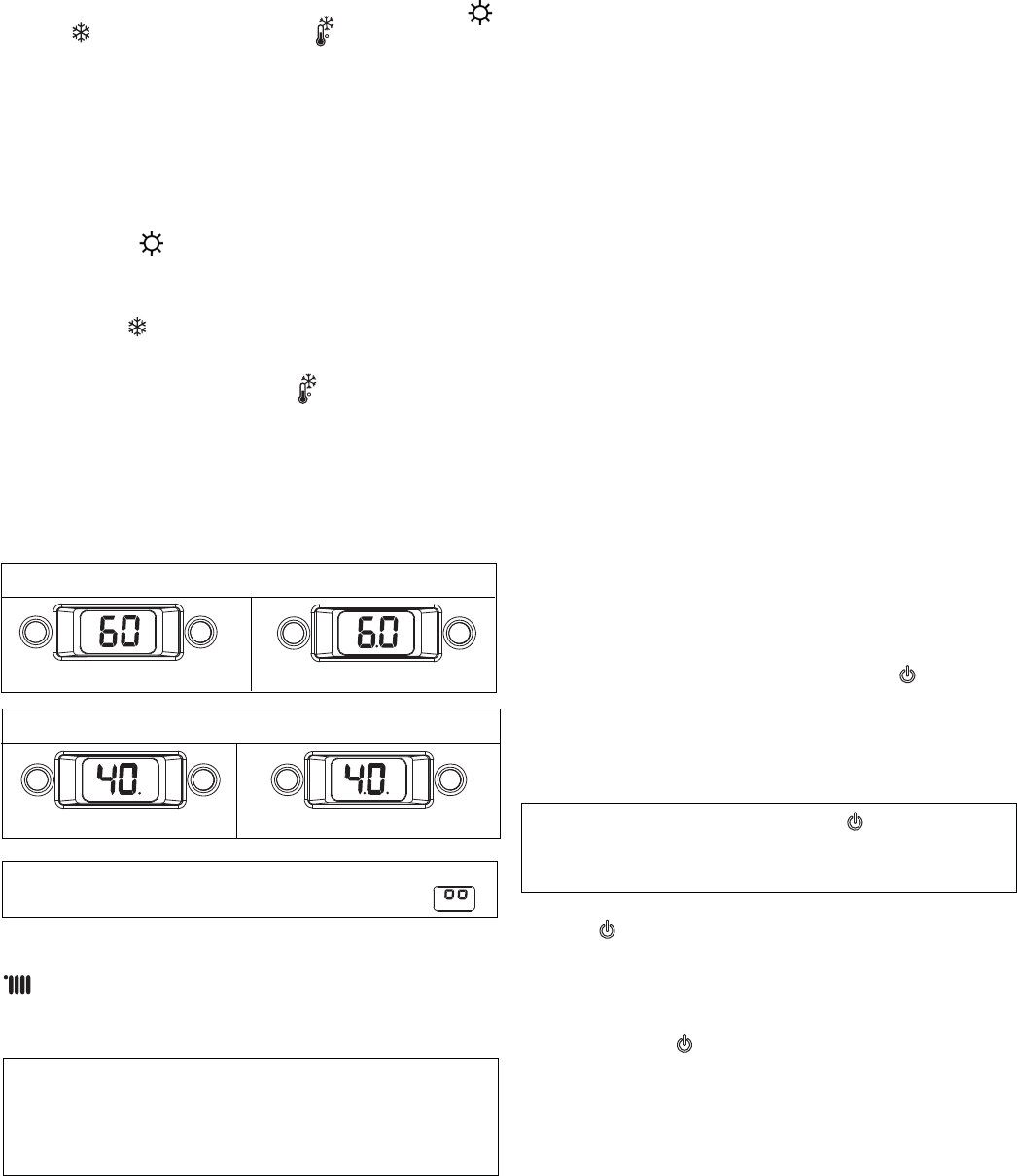

● (dot in the middle)= means hundred (Fig.43)

● (dot on RIGHT side)= means DHW mode (Fig. 44)

example:

NOTICE:

For temperature over 199°F (93°C) the display shows

.

Adjusting heating water temperature

To adjust the heating water temperature turn the knob marked

(Fig. 50) clockwise to increase and counterclockwise to

decrease.

When turning the knob, the required temperature automatically

appears on the digital display.

NOTICE: Depending on the type of system, it is possible to

pre-select the suitable temperature range:

- standard systems 104-176°F (40-80°C)

- floor systems 68-113°F (20-45°C).

For further details, consult the “Boiler configuration” (Fig. 61)

3. ADJUSTING HEATING WATER TEMPERATURE WITH

AN OUTDOOR PROBE CONNECTED

When an outdoor probe is connected, the value of the delivery

temperature is automatically chosen by the system which rapidly

adjusts ambient temperature to the changes in outdoor tempe-

DHW mode

40°F 140°F

60°F 160°F

Heating mode

Fig. 43

Fig. 44

rature. To increase or decrease the temperature with respect to

the value automatically calculated by the PCB, turn the heating

water selector (Fig. 50) clockwise to increase and

counterclockwise to decrease.

Adjustment settings range from comfort levels - 5 to + 5 which are

indicated on the digital display when the knob is turned.

4. ADJUSTING DOMESTIC HOT WATER TEMPERATURE

(IF A STORAGE TANK WITH SENSOR AND 3-WAY

VALVE IS INSTALLED)

When turning the knob, the required temperature automatically

appears on the digital display. The domestic hot water adjustment

ranges lies between 95°F (35°C) and 140°F (60°C). When

choosing the temperature, both for heating and domestic hot

water, the display shows the value being selected. About 4

seconds after the selection has been made, the modification is

recorded and the display returns to the delivery or domestic hot

water temperature read by the probe. Priority is always given to

DHW production.

The boiler setting depends from the jumper JP position (Fig. 63).

- CASE A (factory set) heating only + external water tank with

thermostat adjustment inapplicable - jumper in position 3

- CASE B heating only + external water tank with sensor - to

adjust the temperature of the domestic hot water in the water

tank, turn the temperature selector clockwise to increase and

counterclockwise to decrease - jumper in position 2.

5. WORKING THE BOILER

If a programmable timer or ambient thermostat are mounted,

these must be switched on and adjusted to higher than ambient

temperature in order to allow the boiler to start.

The boiler remains on standby until the burner ignites as a result

of a demand for heat. The green indicator LED (B, Fig. 52), located

on the left-hand side of the panel, lights up to indicate the flame

is present. The boiler continues to work until the selected

temperatures have been reached. It then returns to “stand-by”

while displaying delivery temperature.

In the event of a starting or operating fault, the boiler performs a

“SAFETY STOP”: the green indicator LED on the control panel

goes out, a fault code flashes on the display (Fig. 53) and a red

indicator LED (D) lights up in the event of a shutdown. To identify

the fault codes and reset the boiler, consult the “Indicator LEDs

and faults” section.

6. RESET FUNCTION

To reset the boiler, turned the function selector to

(Fig. 54) then

move it to the required position and check that the red indicator

LED has gone out.

At this point, the boiler starts automatically if correct operating

conditions have been restored; when the burner ignites, the green

indicator led lights up and the digital display indicates the

instantaneous operating temperature.

NOTICE: Simply turning the selector to

does not reset the

boiler.

If the boiler continues not to work, call your local Service

Technician.

In normal operating conditions, when the function selector is

turned to

, the digital display indicates “- -” (Fig. 55) unless the

anti-freeze phase (AF - Fig. 56) is in progress or the combustion

analysis function is activated (CO - Fig. 58).

7. SWITCHING OFF

For short absences (weekends, brief journeys, etc.) turn the

function selector to

OFF/RESET.

As the boiler remains powered with the gas tap open, it is

protected by the following systems:

- Freeze protection:

Heating

The function starts if the temperature measured by the flow

sensor falls below 43°F (6°C). In this mode, a heat demand is

generated and the burner ignites at minimum power. This is

maintained until the temperature of the water flow reaches

95°F (35°C).