18

required system volume and capacity, no valve is to be placed

between the boiler and the expansion tank.

6. Install an Air Elimination Device on the system supply if

required, the boiler has two auto air vents built in.

7. Install a drain valve at the lowest point of the system.

Note: The XPak has a proper internal drain valve. (see Fig.

42a)

8. The Safety Relief Valve is installed at the factory. Pipe the

discharge of the safety relief valve to prevent injury in the

event of pressure relief. Pipe the discharge to a maximum of

6” (152 mm) above the floor to a drain. Provide piping that is

the same size as the safety relief valve outlet. Never block the

outlet of a safety relief valve.

11. FILL AND PURGE HEATING SYSTEM

CAUTION:

For installation that incorporates standing Iron

Radiation and systems with manual vents at the high points.

Follow above section and starting with the nearest manual air

vent, open vent until water flows out, then close vent. Repeat

procedure, working your way toward furthest air vent. It may

be necessary to install a basket strainer in an older system

where larger amounts of sediment may be present. Annual

cleaning of the strainer may be necessary.

WARNING:

Use only inhibited propylene glycol solutions

which are specially formulated for hydronic systems. Ethylene

glycol is toxic and can attack gaskets and seals used in

hydronic systems. Glycol mixtures should not exceed 40%.

1.Glycol in hydronic applications which is specially formulated

for this purpose includes inhibitors that prevent the glycol

from attacking metallic system components. Make certain

that the system fluid is checked for the correct glycol

concentration and inhibitor level.

2.The glycol solution should be tested at least once a year and

as recommended by the glycol manufacturer.

3.Anti-freeze solutions expand more than water. Allowances

must be made for this expansion in the system design.

CAUTION: It is highly recommended that you carefully follow

the glycol manufacturer’s recommended concentrations,

expansion requirements and maintenance recommendations

(pH additive breakdown, inhibitor reduction, etc.). You must

carefully calculate the additional friction loss in the system as

well as the reduction in heat transfer co-efficients; pH must be

maintained between 6-8.

8. BOILER WITH DHW TANK

- Connect the external hot-water tank according to the Installation

instructions of the hot-water tank and fittings concerned.

Domestic Hot Water Production via DHW Storage Tank

XPak boilers can be used in conjunction with the stand-alone

DHW storage tanks.

The boiler can control the DHW tank temperature directly from

the boiler control panel. In case a tank sensor is installed (see

boiler configuration jumpers Fig. 61) adjust the tank temperature

via the DHW selector. The display shows the tank temperature if

main selector in proper position.

Boiler can accept also a DHW tank controlled by a thermostat

(see boiler configuration jumpers Fig. 61), in this case the DHW

set point can not be adjusted on the control panel but only on the

tank thermostat (field supplied).

Both cases the supplied water temperature to the tank is 176°F

(80°C) and it goes ahead with priority over heating until the tank

request is satisfied (either the sensor or the termostat open).

The boiler can control a 3-way valve directly from the boiler control

panel (see 3-way installations Fig. 38).

Refer to electrical connections for 3-way valve installation.

Size and select the DHW storage tank based on the forecast

DHW consumption of the building in question.

If different method of DHW production are used, the boiler flow

temperature is set as heating mode (see boiler configuration

jumpers Fig. 61).

9. WATERSIDE FLOW (PRIMARY CIRCUIT)

The boiler is designed only for closed loop, forced circulation hot

water heating systems.

XPak is equipped with an internal 3 speed pump.

PUMP DUTY

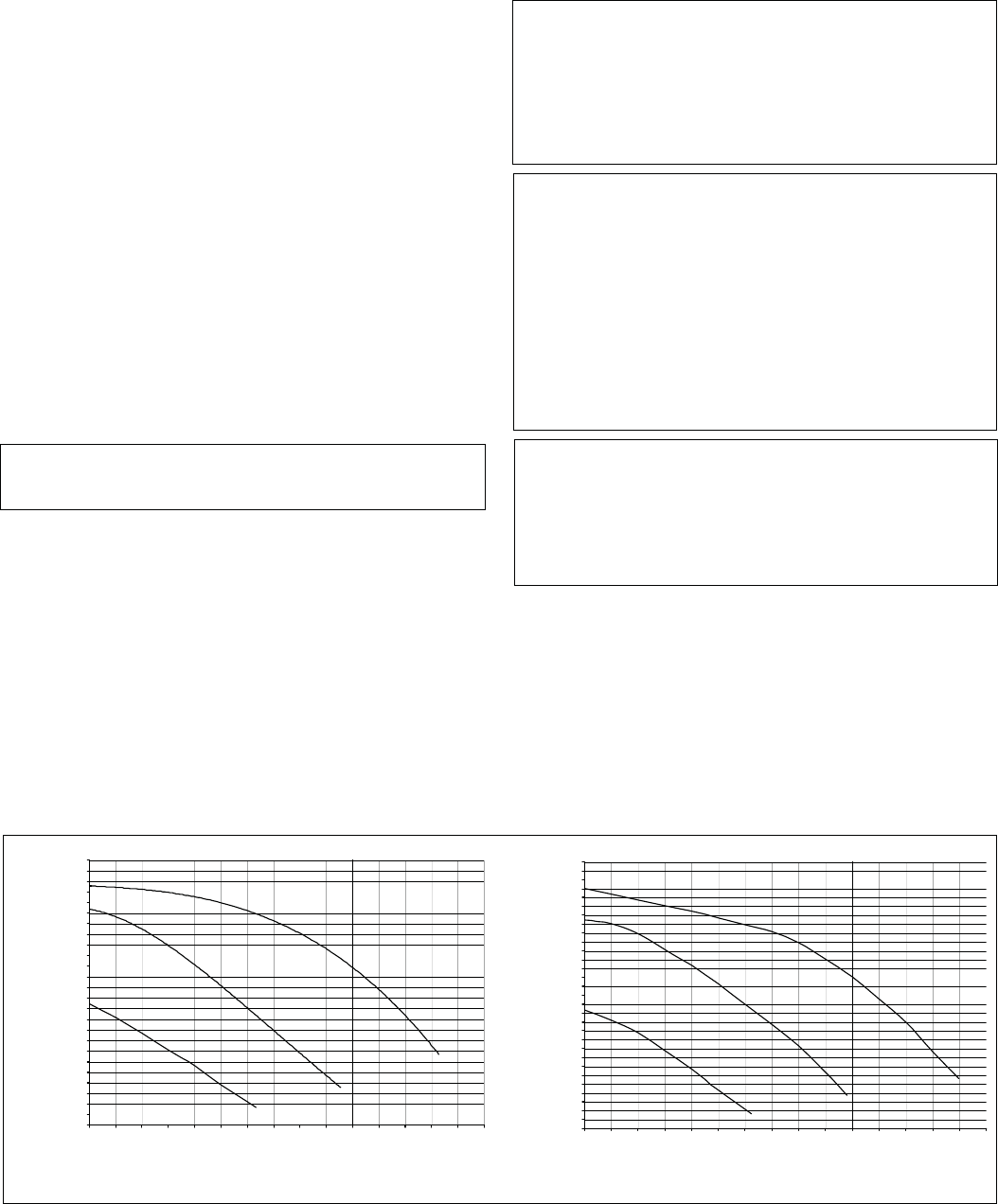

Fig. 6 below shows the flow-rate available – after allowing for

pressure loss through the appliance – for system requirements.

When using this graph, apply only the pressure loss of the system.

The graph is based on a 36°F (20°C) temperature differential.

CAUTION: The XPak should not be operated as a potable

Hot Water Boiler. The XPak should not be operated in a open

system.

10. PROCEDURE SUMMARY

1. Connect the system return marked “In”.

2. Connect the system supply marked “Out”.

3. Install a Back Flow preventor on the Cold Feed Make-Up

Water line.

4. Install a Pressure Reducing Valve if required on the Cold

Feed Make-Up Water line, 15 PSI (1 bar) nominal on the

system return. Check Pressure Gauge which should read

minimum pressure of 12 PSI (0.8 bar)

5. Install an Expansion Tank on the system supply. Consult the

tank manufacturer’s instruction for specific information relating

to expansion tank installation. Size the expansion tank for the

Fig. 6

XPak 85

XPak 120

Flow rate (gph)

Residual head (ftwc)

Residual head (ftwc)

Flow rate (gph)

1st speed

2nd speed

3rd speed

0 20 41 61 81 102 122 142 163 183 203 224 244 264 285 305

16

15

14

12

11

10

9

7

6

5

3

2

0.6

0

0 20 41 61 81 102 122 142 163 183 203 224 244 264 285 305

16

15

14

12

11

10

9

7

6

5

3

2

0.6

0

1st speed

2nd speed

3rd speed