46

5. HEATING MODE

With the selector switch in the ON position (

- -

F

) and any

additional controls (time clock, programmer, room thermostat, etc,)

calling for heat, the appliance will operate in the heating mode. The

pump and fan will be activated via the flow temperature sensor.

When the fan is sensed to be operating correctly (blower signal),

the ignition sequence commences. Ignition is sensed by the

electronic circuitry to ensure flame stability at the burner. Once

successful ignition has been achieved, the electronic circuitry

increases the gas rate to 75% of the MAX Heating (set by the

corresponding HTG trimmer) for a period of 15 minutes. The speed

of the fan and therefore the output of the boiler is determined by

the temperature of the water sensed by the flow temperature

sensor, consequently a high temperature at the flow sensor results

in a lower fan speed. As the water temperature increases, the

temperature sensors – located on the flow pipe of the boiler –

reduce the fan speed via the electronic circuitry. Depending on

the load, either the water temperature will continue to rise until

the set point is achieved or the water temperature will fall whereby

fan speed will increase relative to the output required. When the

boiler has reached the set point (+ hysteresis), the burner will

switch off. The built-in anti-cycle device prevents the burner from

re-lighting for approximately 3-minutes. When the temperature

of the flow sensor falls below the set point (- hysteresis), the

burner will re-light.

NOTICE:

If the spark/sensing electrode does not sense

ignition the appliance will re-attempt ignition a further 4-times

then go to lockout. When the set-point has been reached

(the position of the heating temperature selector) as

measured at the primary thermistor, the appliance will begin

the modulation phase whereby the fan and gas valve will

continuously modulate to maintain the set-point.

If the temperature continues to rise and exceeds the set-

point by 9°F (5°C) (hysteresis), the burner will shut down. A

new ignition sequence will be enabled when the 3- minute

anti-cycle has been performed and the temperature at the

primary thermistor has dropped 9°F (5°C) (hysteresis) below

the set-point.

NOTICE: When the request for heating and/or hot water has

been satisfied, the appliance pump and fan may continue to

circulate to dissipate any residual heat within the appliance.

6. DHW MODE

With the selector switch in either the hot water only or heating &

hot water position, the appliance will operate in the hot water

mode whenever a tank sensor/thermostat is in request. If there is

a request the pump and fan will be activated via the flow tempe-

rature sensor. When the fan is sensed to be operating correctly

(blower signal), the ignition sequence commences. Ignition is

sensed by the electronic circuitry to ensure flame stability at the

burner. Once successful ignition has been achieved, the

electronic circuit allows the gas rate to achieve the modulation

value.

1. CHECKING APPLIANCE OPERATION

When carrying out any repairs or servicing to the appliance, the

relevant commissioning procedure must be undertaken to

ensure the continued safe operation of the appliance. Particular

attention should be made to ensure gas tightness, water

tightness, and the electrical integrity of the appliance.

2. APPLIANCE MODES OF OPERATION

NOTICE

There must be sufficient system water pressure min 7 psi (0.5 bar)

to ensure the water pressure switch is activated. If there is

insufficient system pressure the pump and fan will be prevented

from operating and the low-pressure fault code will be displayed.

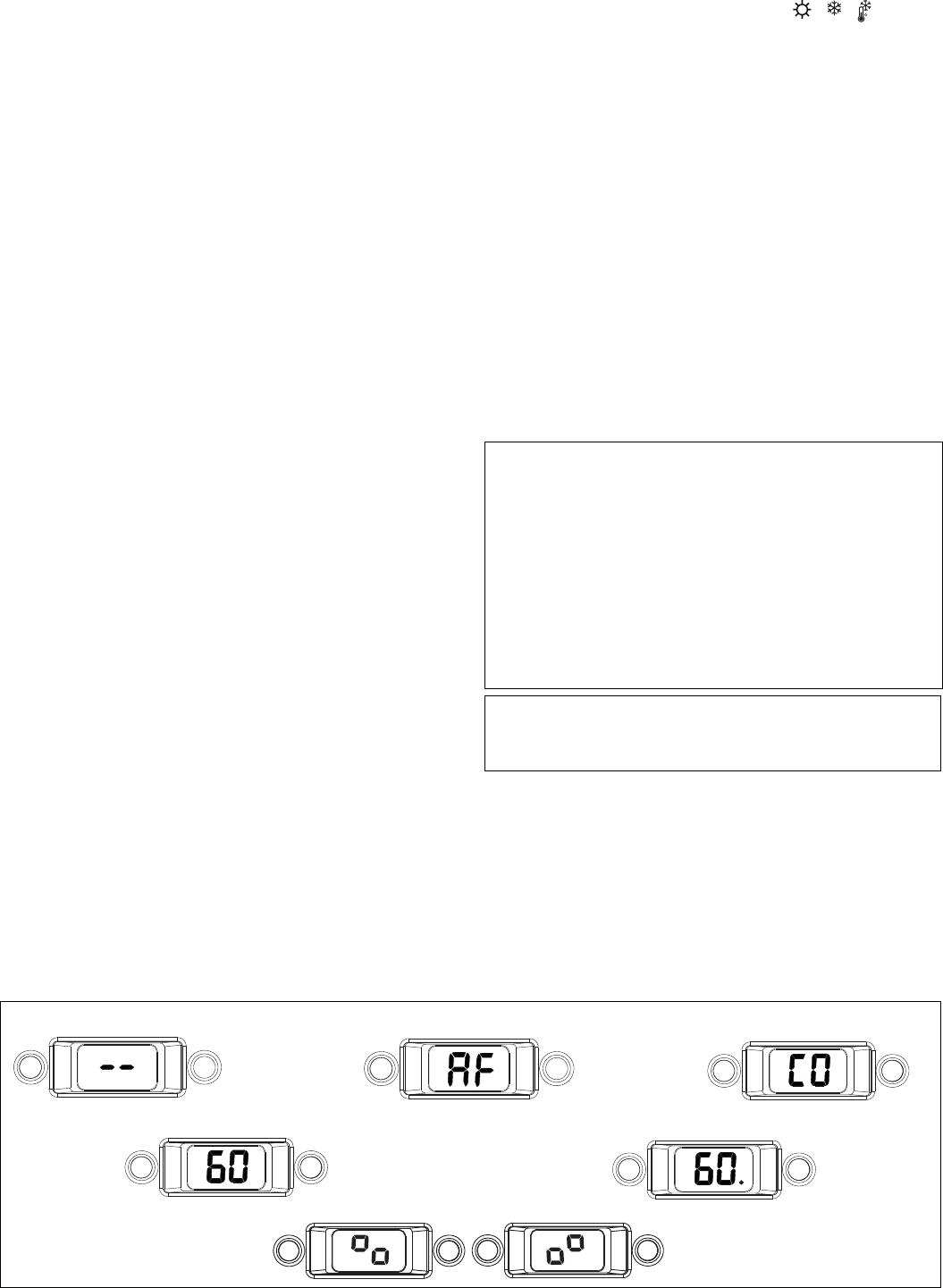

The 2-digit display can show several different modes of

operation.

3. SELECTOR SWITCH IN THE OFF/STAND BY POSITION

When the selector switch is in the Off/reset position, the following

functions are active.

Active functions:

- Freeze protection system

- Pump anti-seize

4. ON-BOARD FUNCTIONS

-

THERMOREGULATION

: When an outdoor air sensor is

connected to the appliance, the electronic circuitry will

automatically adjust the flow outlet temperature to suit local

weather conditions in order to maintain comfort and efficiency. A

specific operating curve that is most suited to the system type

and geographical area can also be selected (Fig. 65).

-

CO FUNCTION

: the CO function when activated, will allow

the appliance to run at maximum and minimum output while a

combustion analysis check is being carried out. While the CO

function is active, all other functions are disabled (minimum

power operating period, anti-cycle, set-point, etc). Once

enabled, the CO function will remain active for a 15-minute

period, or until the function is manually deactivated (refit and

rotate in any direction the main selector switch).

- FREEZE PROTECTION:This function is only active when there

are no requests for heating or DHW. If the temperature drops

below 43°F (6°C), the boiler will operate on minimum power

until the temperature of the primary thermistor reaches 95°F

(35°C). Thereafter the pump & fan will post-purge for 30-seconds.

- ANTI-CYCLE FUNCTION: The anti-cycle function ensures

the burner remains switched off for at least 3-minutes after the

set-point hysteresis (set-point + 9°F (5°C)).

- PUMP ANTI-SEIZE FUNCTION: When there has been no

heating or DHW request for 24-hours, the anti-seize cycle is

activated. The pump will be activated for a period of 30-seconds.

- ACTUATOR ANTI-SEIZE FUNCTION: When there has been

no heating or DHW request for 24-hours, the anti-seize cycle is

activated. The divertor valve actuator (3-way valve) will cycle

briefly to the heating position, and then back to the DHW position.

11 - CHECKS, ADJUSTMENTS AND FAULT FINDING

Freeze protection mode active

Combustion analysis mode active

Normal heating request (example 140°F (60

o

C)).

Normal DHW request (example 140°F (60

o

C))

OFF/reset position

Fig. 58

Purge cycle mode active