Sewing

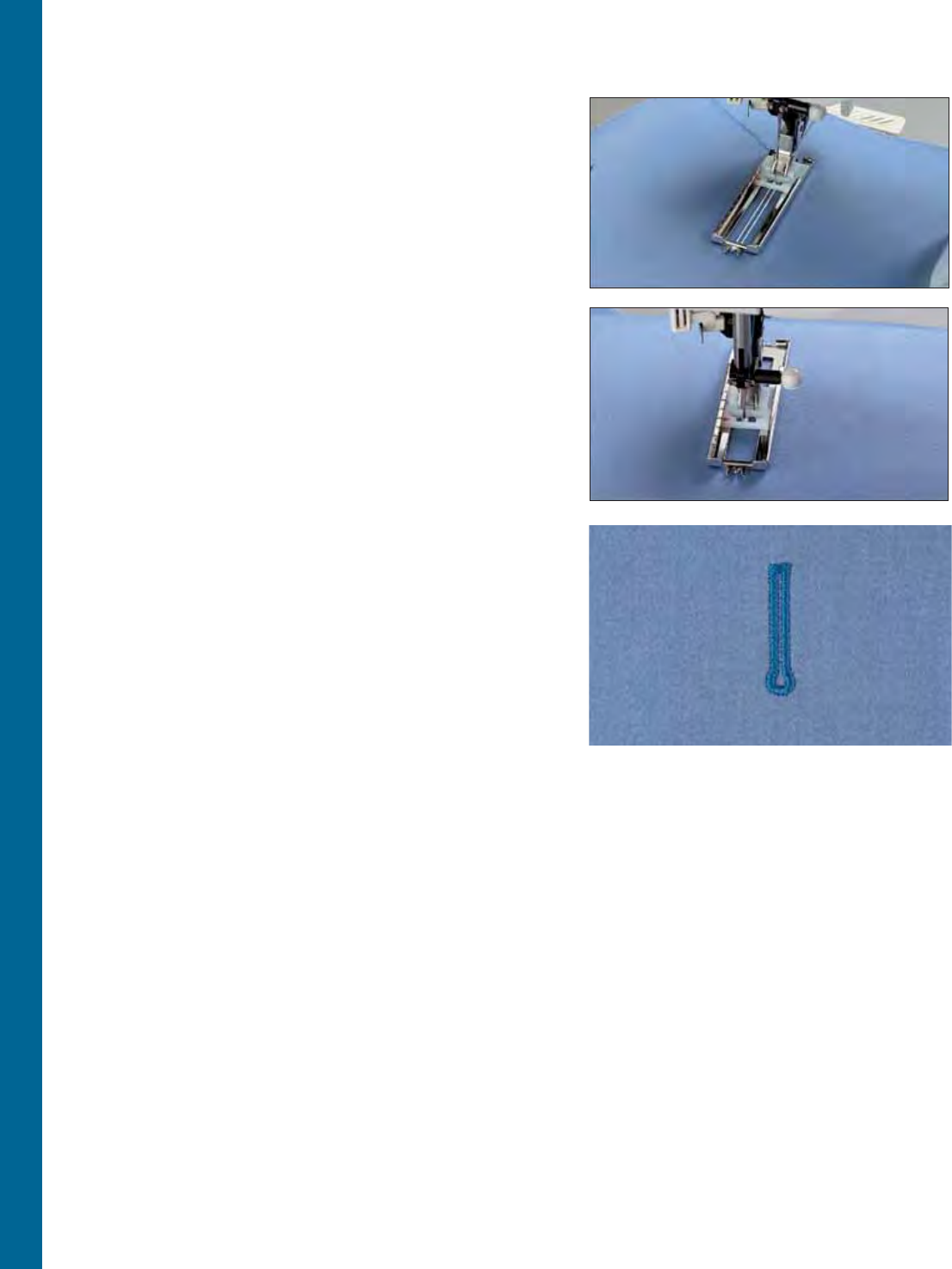

2. Attach the buttonhole foot and pull it backward as far as the second

red mark. Before starting to sew, press the “needle down” button.

3. Sew the right side of the buttonhole.

4. After the machine sews the fi rst few stitches of the curved end pull

the gimp thread down from the clamp with a straight pin.

Note: The presser foot must not be raised from the fabric!

5. Pull the gimp thread on the left towards the rear until the loop is

just in front of the needle. Carefully sew the curve, guiding the

gimp thread under the stitching.

6. After sewing the curve, hold the gimp thread slightly taut and

fi nish sewing the buttonhole.

7. Thread the gimp threads into a needle and pull them to the wrong

side of the garment. Tie the gimp threads and cut off the excess

thread.

The round buttonhole with gimp thread is sewn in the same way.

Note: This buttonhole is particularly attractive when sewn with a heavier-weight thread.

Buttonhole tips

Buttonholes that are to be sewn very close to a reinforced edge, may

sometimes not feed optimally with the buttonhole foot because of the

bulk at the edge of the fabric. In this case, use presser foot 1A with the

Integrated Dual Feed engaged.

Fabrics that shift or stretch easily should be reinforced with water-

soluble or lightweight stabilizer.

Buttonholes are particularly stable and durable if a gimp cord is

inserted while sewing (see " Buttonholes, with gimp cord").

Linen buttonholes are particularly attractive if you use a heavier-

weight thread through a topstitch needle.

Buttonholes are normally selected a little larger than the button

diameter. It is important to always sew a test buttonhole on the same

fabric/stabilizer as your project.

Cut open all buttonholes carefully. Open the curve of the keyhole

buttonhole with a belt punch or awl.

3:18