11

Accessories

Starting

When the band conveyor is started for the first time, the belt’s position on the

rollers should be checked. The belt must not move obliquely.

If the belt moves obliquely.

When the belt moves obliquely. Screw one adjusting screw at a time. Only screw

a 1/4 turn. Wait and let the belt move for a few minutes. Check, adjust, wait, and

check again until the belt moves straight.

Belt tension.

The conveyor belt’s length has 1% tolerance. Never tension the belt’s adjusting

screws with a greater tightening torque than 5 Nm.

Maintenance

During all maintenance work on the band conveyor, both the circuit-breaker and

the main circuit-breaker must be “Off”. Alternatively, the connector must be pulled

out of the power point!

Regularly check the conveyor belt’s wear and its position on the rollers. The belt

must not move obliquely! Adjust as necessary according to the instructions under

“Starting - If the belt moves obliquely” (see previous Section).

Clean the belt using a light cleaning agent. Do not use any sharp objects, strong

cleaning agents or chemicals which can damage the belt.

Trouble-shooting

If the band conveyor does not start

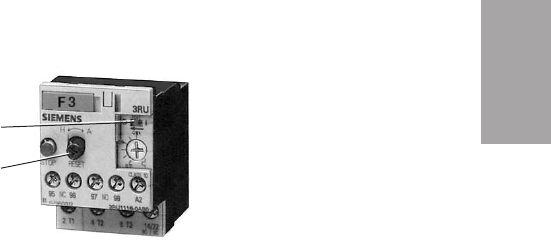

The conveyor belt motor has an overload circuit

breaker, F3, in the distribution cabinet, which trips

if you jam or overload the conveyor belt.

This is indicated in the window (A) which then

shows an “0”.

To reset, press the “reset” button (B).

Also check the wiring diagram in Section 9, additions and modifications can occur.

A

B

Accessories l 11-7