Example

The granulator is equipped with a current sensing relay to control a conveyor.

A motor of 7.5 kW has a rated current of about 15 A.

When this star/delta is started, it pulls about 15 A/ i.e. about 9 A per phase.

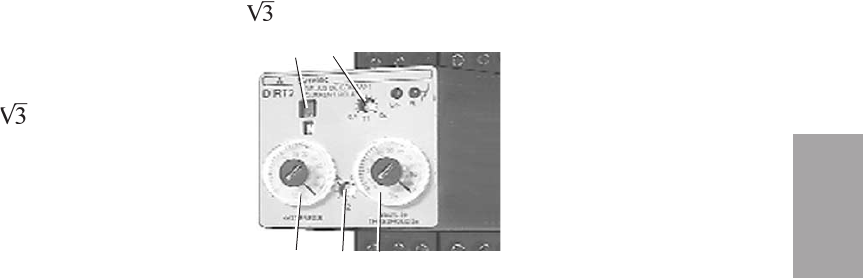

Relay Setting:

Motor size 15 A/ = 8,7 A per phase

T1 – Start delay setting 0.1 second.

T2 – Reaction time setting 3.0 seconds.

A – Hysteresis 20 %.

B – Limit value 30 %.

C – Relay function N normal.

• The current transformer size is 30/1A.

• The current transformer is connected to E2 (1 A).

• In a current transformer with a transformation ratio of 30/1, the limit value

B should be set to 30 % or 9 A (30 A = 100 %).

• The current sensing relay detects the current consumption of the granulator

motor and stops the conveyor, when the granulator motor exceeds 9 A for

3 seconds, to prevent further material from being fed into the hopper.

• The relay re-starts the conveyor automatically when the granulator motor

consumption has fallen 20 % below 9 A, i.e. to 7 A without a time delay.

A T2 B

C T1

9

Wiring Diagram

Wiring Diagram l 9-5