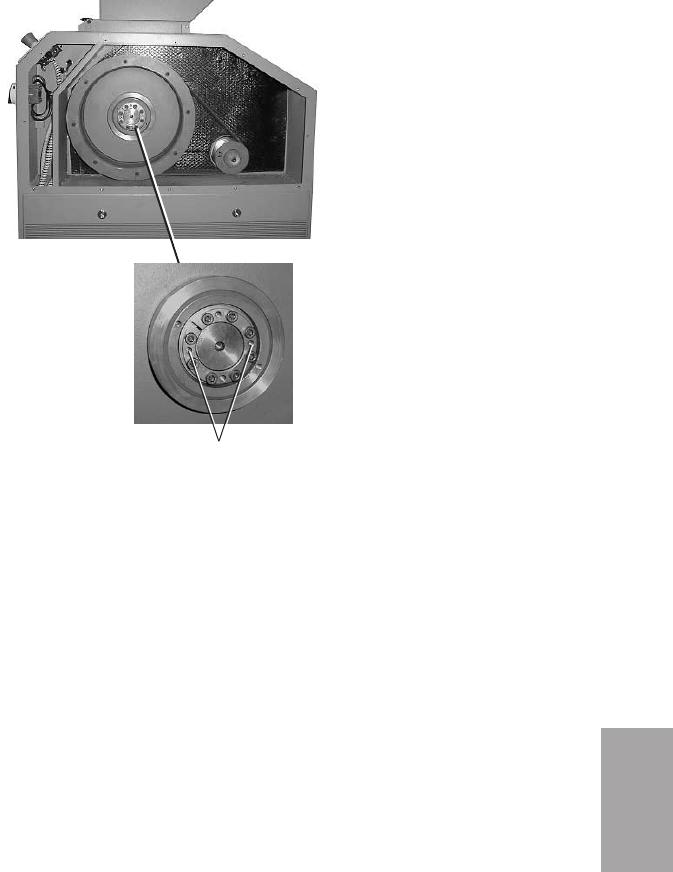

Cutter Pulley/Motor Pulley

The upper panel on the right-hand side of the granulator must be removed to

remove/install the cutter or motor pulleys.

This makes the cutter and motor pulleys accessible.

Removal

Cutter Pulley

The pulley is mounted with a compres-

sion bush.

• Undo all screws a few turns (8 pcs.)

• Remove two screws.

• Put a drop of oil into the extractor

hole (A), and insert the two screws.

• Tighten the screws, using progressively

increased torque until the compression

bush comes away from the shaft.

• Lift off the cutter pulley, complete with the

compression bush, from the shaft.

Motor Pulley

• Undo the socket cap screw on the pulley.

• Remove the pulley with a puller.

Installing

Motor Pulley

Lift the pulley onto the motor shaft, make sure that the key fits.

• Tighten the pulley with the socket cap screws on the shaft,

88.5lb-ft (120 Nm).

Cutter Pulley

The pulley is fitted with a compression bush.

• Clean and degrease the cutter pulley.

• Oil the cutter shaft.

• Oil the screws and fit the compression bush lightly on the pulley.

• Lift the pulley on to the cutter shaft.

• Make sure that the pulleys line up.

• Tighten the screws in the compression bush.

Tighten the screws alternately with the same torque, progressively

increasing the torque to 14.8lb-ft (20 Nm).

• Tap the compression bush between the shaft and the screws.

Use a block of wood or plastic.

• Tighten the pulley with the compression bush.

Tighten the screws with alternating increased torque to 29.5lb-ft (40 Nm).

A

7

Service

Service l 7-11