57

NOTE: Do not use automobile anti-freeze, or any other fluid

that is not approved for heat exchanger duty. Only use appro-

priately inhibited glycols, concentrated to provide adequate

protection for the temperature considered.

SYSTEM PRESSURIZATION — A proper initial cold fill

pressure must be established before filling of the unit. The

initial cold fill pressure is the pressure applied at the filling

point to fill a system to its highest point, plus a minimum

pressure at the top of the system (4 psig minimum [27.6 kPa])

to operate air vents and positively pressurize the system. The

expansion tank is very important to system pressurization. The

expansion tank serves several purposes:

1. Provide NPSHR (Net Positive Suction Head Required)

for the pump to operate satisfactorily.

2. Set system pressure.

3. Accommodate expansion/contraction of water due to

temperature changes.

4. Acts as a pressure reference for the pump.

The expansion tank pressure must be set BEFORE the

system is filled. Follow the manufacturer’s recommendation

for instructions on setting the pressure in the expansion tank.

NPSHR information is provided on the Pump Curves in

Fig. 33-36 for units with factory-installed hydronic kits. See

Table 4 for pump impeller sizes.

Once the system is pressurized, the pressure at the connec-

tion point of the expansion tank to water piping will not change

unless the water loop volume changes (either due to addition/

subtraction of water or temperature expansion/contraction).

The pressure at this point remains the same regardless of

whether or not the pump is running.

Since the expansion tank acts as a reference point for the

pump, there cannot be two reference points (two expansion

tanks) in a system, unless manifolded together. Where two or

more 30XA chillers with the hydronic option are installed in

parallel, there should not be more than one expansion tank in

the system, unless manifolded together as seen in Fig. 27. It is

permissible to install the expansion tank(s) in a portion of the

return water line that is common to all pumps, providing that

the tank is properly sized for combined system volume.

If the application involves two or more chillers in a primary

secondary system, a common place for mounting the expan-

sion tank is in the chilled water return line, just before the

decoupler. See Fig. 27 for placement of expansion tank in

primary-secondary systems.

If a diaphragm expansion tank is utilized (a flexible

diaphragm physically separates the water/air interface) it is not

recommended to have any air in the water loop. See the section

on air separation on page 51 for instructions on providing air

separation equipment.

FILLING THE SYSTEM — The initial fill of the chilled

water system must accomplish three goals:

1. The entire piping system must be filled with water.

2. The pressure at the top of the system must be high enough

to vent air from the system (usually 4 psig [27.6 kPa] is

adequate for most vents).

3. The pressure at all points in the system must be high

enough to prevent flashing in the piping or cavitation in

the pump.

The pressure created by an operating pump affects system

pressure at all points except one — the connection of the

expansion tank to the system. This is the only location in the

system where pump operation will not give erroneous pressure

indications during the fill. Therefore, the best location to install

the fill connection is close to the expansion tank. An air vent

should be installed close by to help eliminate air that enters

during the fill procedure.

When filling the system, ensure the following:

1. Remove temporary bypass piping and cleaning/flushing

equipment.

2. Check to make sure all drain plugs are installed.

Normally, a closed system needs to be filled only once. The

actual filling process is a fairly simple procedure. All air should

be purged or vented from the system. Thorough venting at high

points and circulation at room temperature for several hours is

highly recommended.

NOTE: Local codes concerning backflow devices and other

protection of the city water system should be consulted and

followed to prevent contamination of the public water supply.

This is critical when antifreeze is used in the system.

SET WATER FLOW RATE — Once the system is cleaned,

pressurized, and filled, the flow rate through the chiller needs

to be established. On units with the hydronic package, this can

be accomplished by using the balancing valve. Follow the

manufacturer’s recommendations for setting the balancing

valve. Local codes may prohibit restricting the amount of water

using the balancing valve for a given motor horsepower. In this

case, use the method listed in the Pump Modification/

Trimming section. See below for the type of combination valve

in 30XA units with the optional hydronic package.

NOTE: Carrier recommends a differential pressure gage when

measuring pressures across the pumps or balancing valves.

This provides for greater accuracy and reduces error build-up

that often occurs when subtracting pressures made by different

gages.

A rough estimate of water flow can also be obtained from

the pressure gages across the 30XA heat exchanger.

Figure 33 and 34 shows the relationship between gpm and

heat exchanger pressure drop. It should be noted that these

curves are for fresh water and “clean” heat exchangers; they do

not apply to heat exchangers with fouling. To read the chart,

subtract the readings of the two pressure gages on the hydronic

kit. This number is the pressure drop across the heat exchanger.

Adjust the factory-installed balancing valve or external balanc-

ing valve (in units without hydronic package) until the correct

pressure drop is obtained for the required flow.

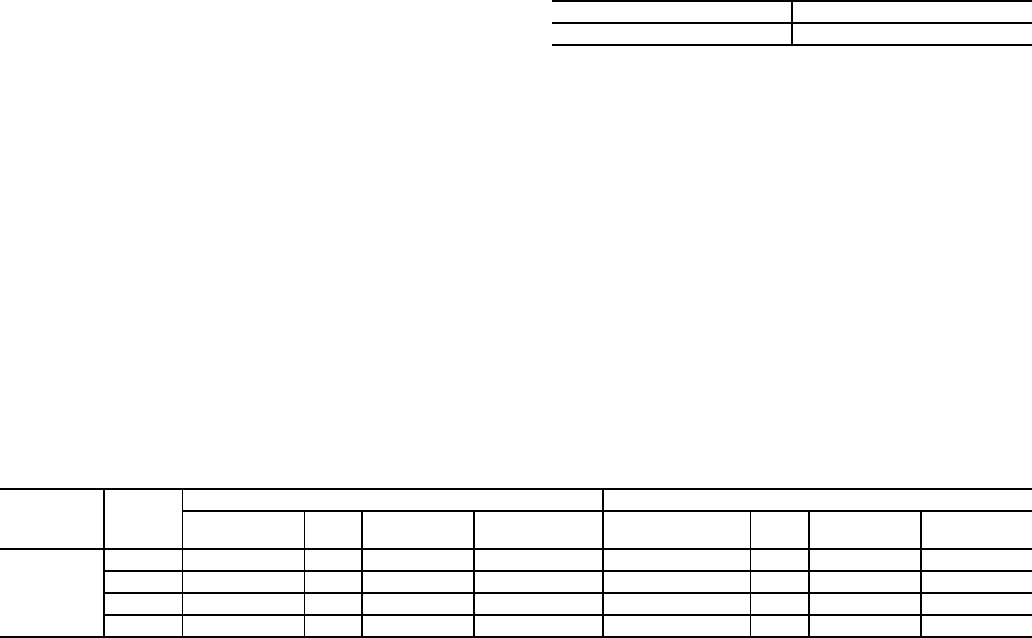

Table 4 — Pump Impeller Sizes

*Option Code refers to the Hydronics Option (position 11) in the model number. See Fig. 1 for option identification.

30XA UNIT SIZE SINGLE/DUAL PUMP

090-160 FTV-5 in.

30XA

UNIT SIZE

PUMP

Hp

SINGLE PUMP DUAL PUMP

Option Code* Rpm

Impeller Dia.

(in.)

Pump Curve Option Code* Rpm

Impeller Dia.

(in.)

Pump Curve

090-160

5 1 3450 4.5 I 7 3450 4.5 II

7.5 2 3450 5 I 8 3450 5 II

10 3 3450 5.4 I B 3450 5.4 II

15 4 3450 6.1 I C 3450 6.1 II