52

The combination valve performs the following functions:

• drip-tight shut-off valve

• spring closure design with a non-slam check valve

• flow-throttling valve

When facing the cooler side of unit, the inlet (return) water

connection is on the bottom. The outlet (supply) water connec-

tion is on the top. The inlet is connected to the suction guide/

strainer of the pump via a Victaulic-type connection. The cool-

er supply has water-side Victaulic-type connections (follow

connection directions as provided by the coupling manufactur-

er). Provide proper support for the piping. If accessory security

grilles have been added, holes must be cut in the grilles for

field piping and insulation.

There is a factory supplied, insulated 45-degree elbow pipe

and a victaulic coupling shipped with units ordered with a

hydronic pump package. Before starting field piping, use the

victaulic coupling to connect this elbow pipe to the outlet of the

combination valve.

The suction guide/strainer is shipped from the factory with a

run-in screen. This screen is a temporary device used during

the start-up/clean-up process of the chilled water circuit to

prevent construction debris from damaging the pump or

internal tubes of the cooler. After all debris has been removed

or a maximum of 24 running hours the temporary screen must

be removed. See the Start-Up, Controls, Operation and

Troubleshooting guide for further information.

NOTE: It is required that a 20 mesh field-supplied strainer be

installed in the inlet piping to the cooler on open loop systems.

A

3

/

4

in. NPT fitting is installed in the inlet piping of the

pump for connection to an expansion tank. Install the tank in

accordance with the manufacturer's instructions.

Figures 25 and 26 illustrate typical single and dual pump

packages.

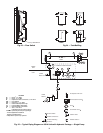

Three drain connections are provided and are located at

leaving water (supply) end of cooler, pump volute, and the

suction guide. See Fig. 2-14 for connection location. Insulate

the drain piping (in the same manner as the chilled water pip-

ing) for at least 12 in. (305 mm) from the cooler.

UNITS WITHOUT HYDRONIC PUMP PACKAGE — When

facing the cooler side of the unit, the inlet (return) water connec-

tion is on the bottom. It is required that a field-supplied strainer

with a minimum size of 20 mesh be installed within 10 ft

(3.05 m) of the cooler inlet to prevent debris from damaging

internal tubes of the cooler. The outlet (supply) water connection

is on the top. The cooler has water-side victaulic-type connec-

tions (follow connection directions as provided by the coupling

manufacturer). Provide proper support for the piping. If accesso-

ry security grilles have been added, holes must be cut in the

grilles for field piping and insulation. See Fig. 28 for a typical

piping diagram of a 30XA unit without a hydronic pump pack-

age.

A drain connection is located at the leaving water (supply)

end of cooler. See Fig. 2-14 for connection location. Insulate

the drain piping (in the same manner as the chilled water

piping) for at least 12 in. (305 mm) from the unit.

DUAL CHILLER CONTROL — the Co mfort Link™ con-

troller allows 2 chillers (piped in parallel or series) to operate as a

single chilled water plant with standard control functions

coordinated through the master chiller controller. This standard

ComfortLink feature requires a communication link between the

2 chillers.

There are several advantages to this type of control:

• redundancy (multiple circuits)

• better low load control, (lower tonnage capability)

• lower rigging lift weights (2 machines rather than 1 large

machine)

• chiller lead-lag operation (evens the wear between the

two machines)

Dual Chiller Leaving Water Sensor

—If the dual chiller algo-

rithm is used, and the machines are installed in parallel, a dual

chilled water sensor must be installed for each module. Install

the well in the common leaving water header. See Fig. 21. The

series dual chiller application is shown in Fig. 22.

Parallel Dual Chiller Operation

— Parallel chiller operation

is the recommended option for dual chiller control. In this case,

each chiller must control its own dedicated pump or isolation

valve. Balancing valves are recommended to insure proper

flow in each chiller. Two field-supplied and installed dual chill-

er leaving water temperature sensors are required, one for each

module for this function to operate properly.

Consider adding additional isolation valves to isolate each

chiller to allow for service on a machine, and still allow for par-

tial capacity from the other chiller. See Fig 21.

Series Dual Chiller Operation

— Series chiller operation is an

alternate control method supported by the ComfortLink™

control system. Certain applications might require that the two

chillers be connected in series. For nominal 10º F (5.6º C) cool-

er ranges, use the minus 1 pass cooler arrangements to reduce

the fluid-side pressure drop. Use the standard cooler pass

arrangement for low flow, high cooler temperature rise

applications.

Consider adding additional piping and isolation valves to

isolate each chiller to allow for service on a machine, and still

allow for partial capacity from the other chiller. See Fig. 22.

CAUTION

The suction guide/strainer is shipped from the factory with

a run-in screen. This temporary screen must be removed

after all debris has been removed or a maximum of 24 run-

ning hours. Failure to remove the temporary screen may

result in damage to the pump or cooler.

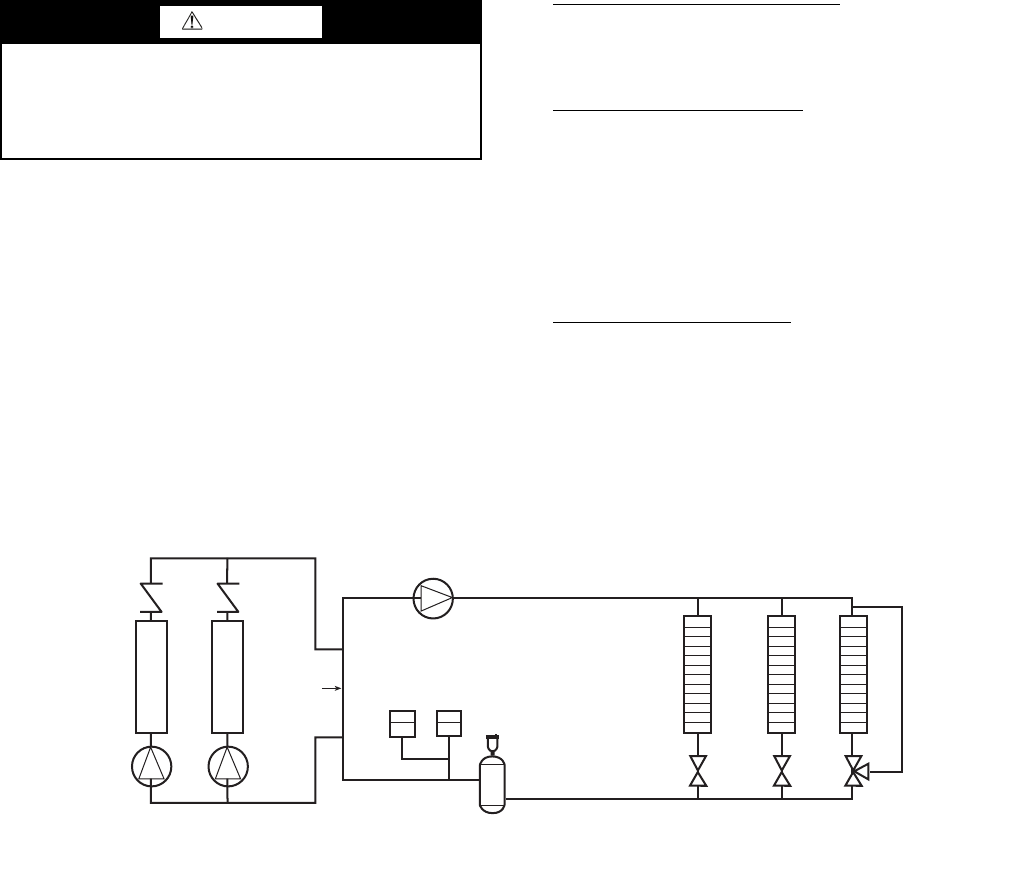

Distribution Pump

Expansion

Tank(s)

Air Separator

with Vent

Decoupler

Chiller 1

Chiller 2

Zone 1

Zone 2

Zone 3

NOTE: Expansion tanks for 30XA hydronic kits must be installed for chillers piped in parallel in the primary water loop.

Fig. 27 — Typical Air Separator and Expansion Tank Location on Primary-Secondary Systems

a30-4002