51

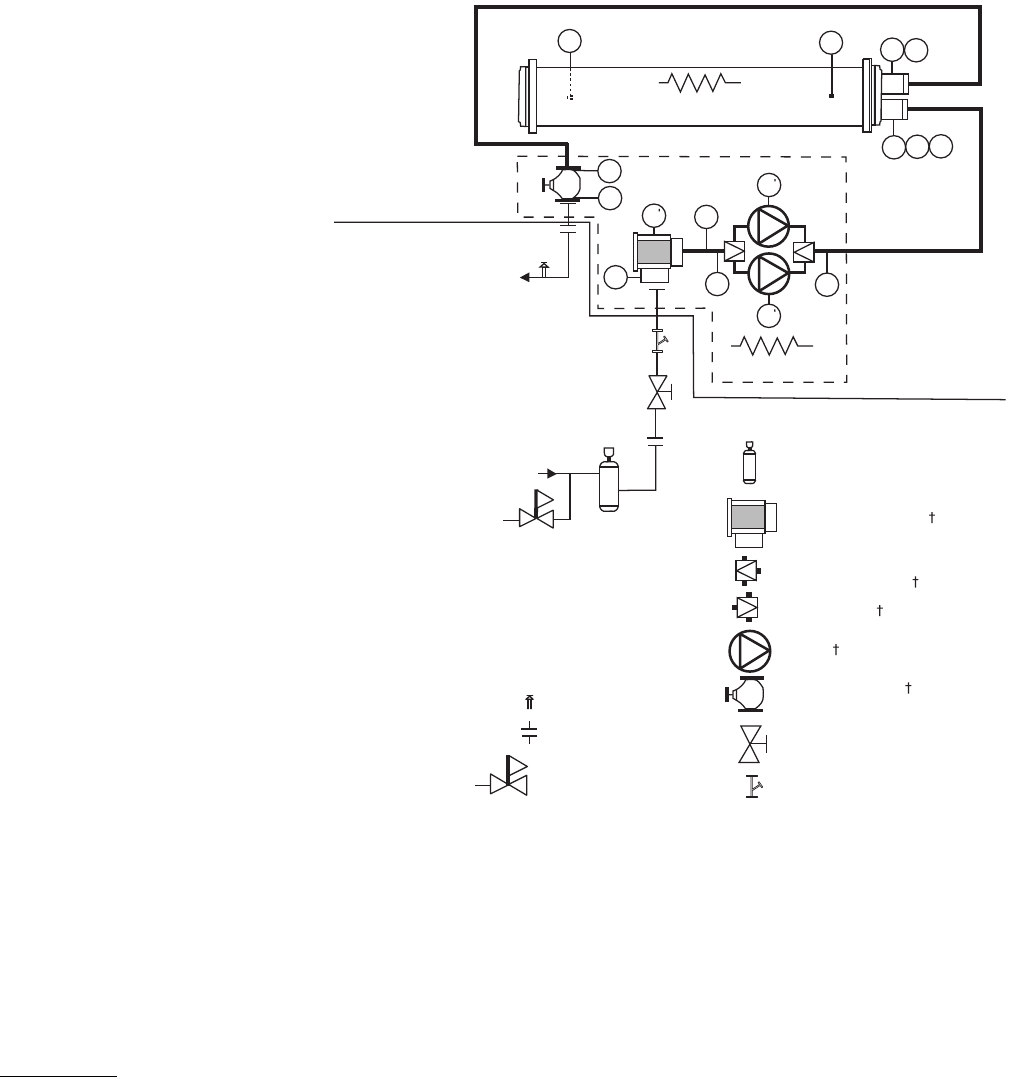

NOTE: It is recommended for units with the hydronic package

that an inlet isolation (shut-off) valve be placed exterior to the

unit to allow removal and service of the entire pump assembly,

if necessary. The hydronic package is supplied from the factory

with a combination valve for isolation of leaving water. Also,

if the unit is isolated with valves, a properly sized pressure

relief valve is recommended and should be installed in the pip-

ing between the unit and the valves, following all applicable

local codes.

Air Separation

— For proper system operation, it is essential

that water loops be installed with proper means to manage air

in the system. Free air in the system can cause noise, reduce

terminal output, stop flow, or even cause pump failure due to

pump cavitation. For closed systems, equipment should be

provided to eliminate all air from the system.

The amount of air that water can hold in solution depends

on the pressure and temperature of the water/air mixture. Air is

less soluble at higher temperatures and at lower pressures.

Therefore, separation can best be done at the point of highest

water temperature and lowest pressure. Typically, this point

would be on the suction side of the pump as the water is return-

ing from the system or terminals. This is generally the optimal

place to install an air separator, if possible.

1. Install automatic air vents at all high points in the system.

(If the 30XA unit is located at the high point of the sys-

tem, a vent can be installed on the piping leaving the heat

exchanger on the

1

/

4

in. NPT female port.)

2. Install an air separator in the water loop, at the place

where the water is at higher temperatures and lower pres-

sures — usually in the chilled water return piping. On a

primary-secondary system, the highest temperature water

is normally in the secondary loop, close to the decoupler.

Preference should be given to that point on the system

(see Fig. 27). In-line or centrifugal air separators are read-

ily available in the field.

It may not be possible to install air separators at the place of

the highest temperature and lowest pressure. In such cases,

preference should be given to the points of highest temperature.

It is important that the pipe be sized correctly so that free air

can be moved to the point of separation. Generally, a water

velocity of at least 2 feet per second (0.6 m per second) will

keep free air entrained and prevent it from forming air pockets.

Automatic vents should be installed at all physically elevated

points in the system so that air can be eliminated during system

operation. Provisions should also be made for manual venting

during the water loop fill.

UNITS WITH HYDRONIC PUMP PACKAGE — The

30XA090-160 units can be equipped with a factory-installed

hydronic pump package consisting of a suction guide/strainer,

pump, combination valve, internal piping and wiring con-

nected at the factory.

PT

PT

T1

PP

PP

D

D

V

D

PT

PT

Chilled

Water Out

Heater

Heater

E

D

PT

Air Separator with Vent*

Strainer/Suction Guide

Reverse Flow Check

Valve/Service Valve

Pump

Service Valve

Combination Valve

Isolation Valve*

Pressure Reducing

Fill Valve*

Flexible Connections*

Pressure Relief*

Chilled

Water In

HYDRONIC PUMP PACKAGE

INSIDE

UNIT

OUTSIDE

UNIT

20 Mesh Stainer**

T2

FS

LEGEND

*Field-supplied and installed.

†Factory-installed option.

**Required for open loop systems.

D—Drain,

3

/

4

-in. NPT

D — Drain,

1

/

4

-in. NPT

E—Expansion Tank Connection,

3

/

4

-in. NPT

FS — Flow Switch

PP — Pipe Plug,

1

/

4

-in. NPT

PT — Pressure/Temperature Tap

T1 — Leaving Water Thermistor

T2 — Entering Water Thermistor

V—Vent,

1

/

4

-in. NPT

Fig. 26 — Typical Piping Diagram on 30XA Units with Hydronic Package — Dual Pumps

a30-4415