56

Step 4 — Fill the Chilled Water Loop.

The chilled water pump (if equipped) is rated for 150 psig

(1034 kPa) duty. The maximum cooler fluidside pressure is

300 psig (2068 kPa). Check the pressure rating for all of the

chilled water devices installed. Do not exceed the lowest pres-

sure rated device.

WATER SYSTEM CLEANING — Proper water system

cleaning is of vital importance. Excessive particulates in the

water system can cause excessive pump seal wear, reduce or

stop flow, and cause damage of other components.

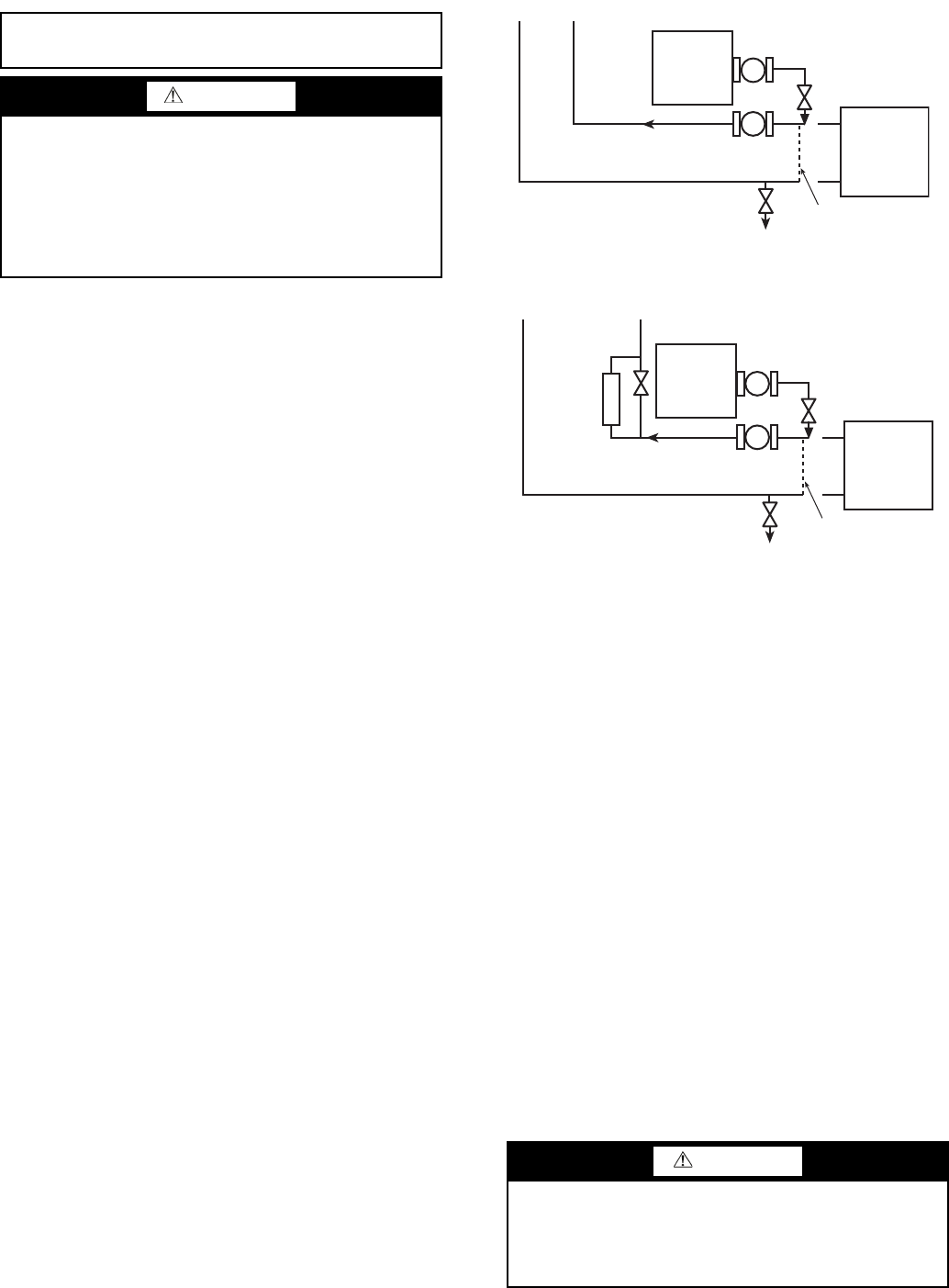

1. Install a temporary bypass around the chiller to avoid

circulating dirty water and particulates into the pump

package and chiller during the flush. Use a temporary

circulating pump during the cleaning process. Also, be

sure that there is capability to fully drain the system after

cleaning. See Fig. 31.

2. Be sure to use a cleaning agent that is compatible with

all system materials. Be especially careful if the system

contains any galvanized or aluminum components. Both

detergent-dispersant and alkaline-dispersant cleaning

agents are available.

3. It is recommended to fill the system through a water me-

ter. This provides a reference point for the future for loop

volume readings, and it also establishes the correct quan-

tity of cleaner needed in order to reach the required

concentration.

4. Use a feeder/transfer pump to mix the solution and fill the

system. Circulate the cleaning system for the length of

time recommended by the cleaning agent manufacturer.

a. After cleaning, drain the cleaning fluid and flush the

system with fresh water.

b. A slight amount of cleaning residue in the system can

help keep the desired, slightly alkaline, water pH of 8

to 9. Avoid a pH greater than 10, since this will

adversely affect pump seal components.

c. A side stream filter is recommended (see Fig. 32 dur-

ing the cleaning process). Filter side flow rate should

be enough to filter the entire water volume every 3 to

4 hours. Change filters as often as necessary during

the cleaning process.

d. Remove temporary bypass when cleaning is complete.

A suction guide with an internal strainer is standard on all

30XA units with factory-installed hydronic packages. This

strainer allows removal of particulates from the chilled

water loop. Using the combination valve and the field-installed

isolation valve at the inlet, the strainer can be isolated from the

chilled water loop to be cleaned.

The Carrier ComfortLink™ controls provided have a built-

in feature to remind building owners or operators to clean the

strainer at a pre-set time interval. Properly installed, cleaned

and maintained systems will rarely need the strainer cleaned

after the initial fill. This time interval is user-configurable.

Ideally, the chilled water loop will be cleaned before the unit

is connected. If the run-in screen is left in the suction guide/

strainer, it is recommended that the Service Maintenance be set

to alert the operator within 24 hours of start-up to be sure that

the run-in screen in the suction guide/strainer is removed after

24 hours of operation.

NOTE: The suction guide/strainer must be removed after the

first 24 hours of operation.

To set the time for the parameter, go to Time

Clock

MCFG

W.FIL in the handheld Navigator™ display.

To set the time for the parameter with the Touch Pilot™ dis-

play, go to Main Menu

Service

MAINTCFG

wfilter_c.

Values for this item are input in days.

WATER TREATMENT — Fill the fluid loop with water (or

brine) and a corrosion-resistant inhibitor suitable for the water

of the area. Consult the local water treatment specialist for

characteristics of system water and a recommended inhibitor

for the cooler fluid loop.

Untreated or improperly treated water may result in corro-

sion, scaling, erosion, or algae. The services of a qualified wa-

ter treatment specialist should be obtained to develop and mon-

itor a treatment program.

IMPORTANT: Before starting unit, be sure all of the

air has been purged from the system.

WARNING

In low ambient (below 32 F [0° C]) and/or low leaving

fluid temperature applications (below 40 F [4.4° C]), a suit-

able antifreeze solution of the proper concentration for the

specific operating conditions must be used as the fluid cir-

culated through the cooler to prevent freezing and damage

to the system. Failure to operate the system with an anti-

freeze solution of the proper concentration will void the

warranty should damage result from freezing.

CAUTION

Water must be within design flow limits, clean, and treated

to ensure proper chiller performance and reduce the poten-

tial of tube damage due to corrosion, scaling, erosion, and

algae. Carrier assumes no responsibility for chiller damage

resulting from untreated or improperly treated water.

x

x

DILUTED

CLEANING

AGENT

SYSTEM

POT FEEDER AND

TRANSFER PUMP

30XA UNIT

TEMPORARY

BYPASS

TEMPORARY

PUMP

TO DRAIN

Fig. 31 — Typical Set Up for Cleaning Process

a30-4411

x

x

DILUTED

CLEANING

AGENT

SYSTEM

SIDE

STREAM

FILTER

POT FEEDER AND

TRANSFER PUMP

30XA UNIT

TEMPORARY

PUMP

TEMPORARY

BYPASS

TO DRAIN

Fig. 32 — Cleaning Using a Side Stream Filter

a30-4412