NOTE: Do not count elbows or pipe sections in terminations or within furnace. See shaded areas in Fig. 40, 41, 42, 43, and 44.

EXAMPLE: An 042080 size furnace located in Indianapolis, elevation 650 ft above sea level, could be installed in an application requiring

3 elbows and 17 ft of vent pipe, along with 5 elbows and 16 ft of combustion-air pipe. Table 7 indicates this application would allow a

1-1/2-in. diameter vent pipe, but require a 2-in. diameter combustion air pipe (1-1/2-in. pipe is good for 20 ft with 3 elbows, but only 10

ft with 5 elbows). Therefore, 2-in. diameter pipe must be used for both vent and combustion-air pipes since larger required diameter must

always be used for both pipes. If same installation were in Albuquerque, elevation 5250 ft above sea level, installation would require 2-in.

vent pipe and combustion-air pipe. At 5001- to 6000-ft elevation, 1-1/2-in. pipe is not allowed with 5 elbows, but 2-in. pipe is good for

68 ft with 5 elbows.

COMBUSTION-AIR AND VENT PIPE ATTACHMENT

NOTE: All pipe joints must be watertight except attachment of combustion-air pipe to inlet housing connection, since it may be necessary to

remove pipe for servicing.

1. Attach combustion-air pipe to furnace as follows:

a. Determine location of combustion-air intake pipe connection to combustion-air intake housing as shown in Fig. 36 for application.

b. Reposition combustion-air intake housing plug fitting in appropriate unused intake housing connection.

c. If required, insert perforated disk assembly (factory-supplied in loose parts bag) in intake housing where combustion-air intake pipe will

be connected. If half disk set is required, install with shoulder of disk against stop in combustion-air inlet.

d. Install pipe support (factory-supplied in loose parts bag) into selected furnace casing combustion-air pipe hole. Pipe support should be

positioned at bottom of casing hole.

e. Insert 2-in. diameter pipe into intake housing.

f. Install casing hole filler cap (factory-supplied in loose parts bag) in unused combustion-air pipe casing hole.

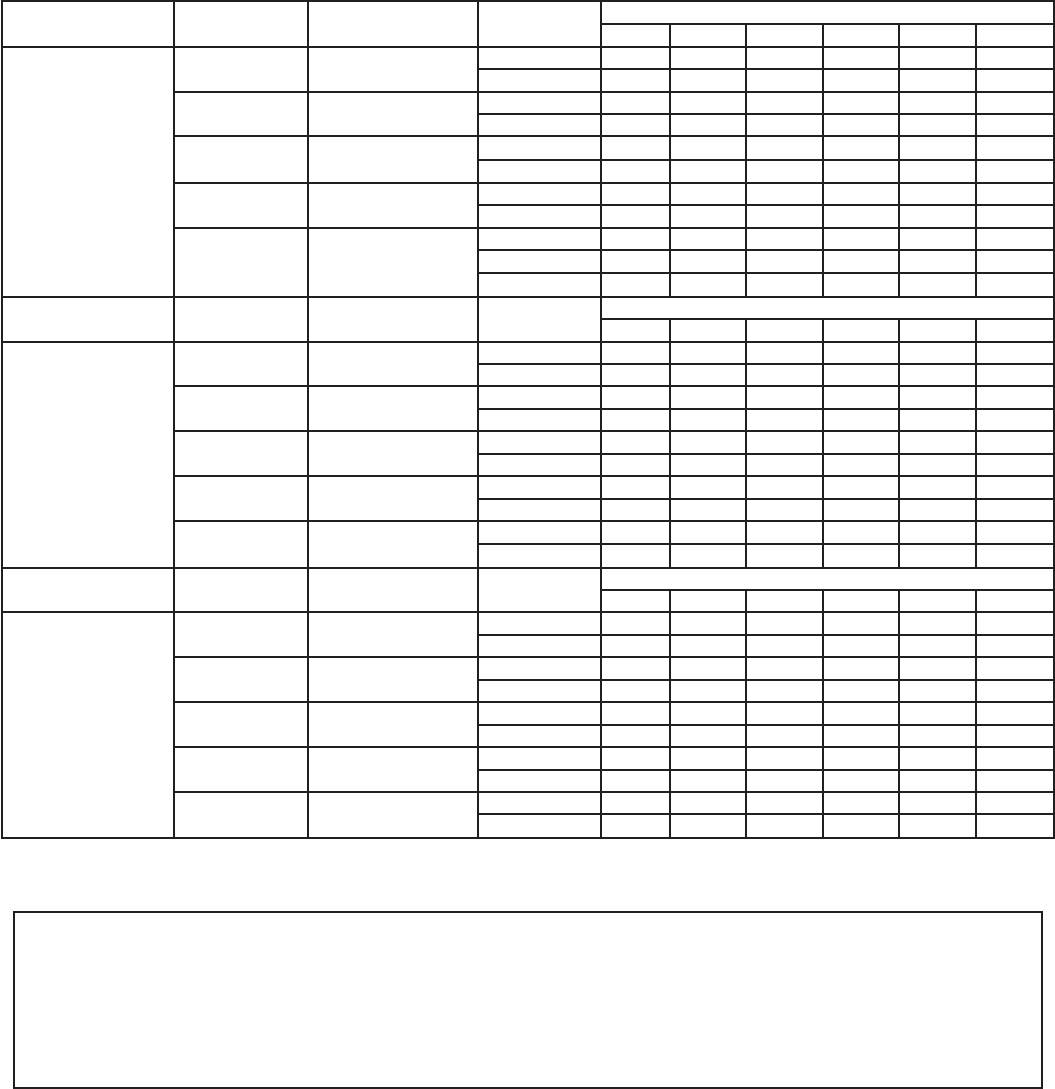

Table 7—Maximum Allowable Pipe Length (ft)

ALTITUDE (FT) UNIT SIZE

TERMINATION

TYPE

PIPE DIA

(IN.)*

NUMBER OF 90° ELBOWS

123456

0 to 2000

042040

2 Pipe or 2-in

Concentric

1-1/2 50 45 40 35 30 25

2 707070707070

042060

2 Pipe or 2-in

Concentric

1-1/2 50 45 40 35 30 25

2 707070707070

042080

060080

2 Pipe or 2-in

Concentric

1-1/2 30 25 20 15 10 5

2 707070707070

060100

2 Pipe or 2-in

Concentric

2 454035302520

2-1/2 70 70 70 70 70 70

060120

2 Pipe or 3-in.

Concentric

2-1/2 10 NA NA NA NA NA

3 3530 15NANANA

3† 70 70 70 70 70 70

ALTITUDE (FT) UNIT SIZE

TERMINATION

TYPE

PIPE DIA

(IN.)*

NUMBER OF 90° ELBOWS

123456

2001 to 3000

042040

2 Pipe or 2-in

Concentric

1–1/2 45 40 35 30 25 20

2 707070707070

042060

2 Pipe or 2-in

Concentric

1–1/2 45 40 35 30 25 20

2 707070707070

042080

060080

2 Pipe or 2-in

Concentric

1–1/2 26 21 16 11 6 NA

2 707070707070

060100

2 Pipe or 2-in

Concentric

2 403530252015

2–1/2 70 70 70 70 70 70

060120

2 Pipe or 3-in.

Concentric

3 3126 12NANANA

3† 63 62 62 61 61 61

ALTITUDE (FT) UNIT SIZE

TERMINATION

TYPE

PIPE DIA

(IN.)*

NUMBER OF 90° ELBOWS

123456

3001 to 4000

042040

2 Pipe or 2-in

Concentric

1-1/2 42 37 32 27 22 17

2 707070707070

042060

2 Pipe or 2-in

Concentric

1-1/2 42 37 32 27 22 17

2 707070707070

042080

060080

2 Pipe or 2-in

Concentric

1-1/2 25 20 15 10 5 NA

2 707070707070

060100

2 Pipe or 2-in

Concentric

2 383328231813

2-1/2 70 70 70 70 70 70

060120

2 Pipe or 3-in.

Concentric

3 2924 10NANANA

3† 59 59 58 57 57 56

See notes at end of table.

—34—