Maintain a 1-in. clearance from combustible materials to supply air ductwork for a distance of 36 in. horizontally from the furnace. See NFPA

90B or local code for further requirements.

B. Ductwork Acoustical Treatment

Metal duct systems that do not have a 90 degree elbow and 10 ft of main duct to the first branch take-off may require internal acoustical lining.

As an alternative, fibrous ductwork may be used if constructed and installed in accordance with the latest edition of SMACNA construction

standard on fibrous glass ducts. Both acoustical lining and fibrous ductwork shall comply with NFPA 90B as tested by UL Standard 181 for Class

1 Rigid air ducts.

C. Supply Air Connections

UPFLOW FURNACES

Connect supply-air duct to 3/4-in. flange on furnace supply-air outlet. The supply-air duct attachment must ONLY be connected to furnace

supply-/outlet-air duct flanges or air conditioning coil casing (when used). DO NOT cut main furnace casing to attach supply side air duct,

humidifier, or other accessories. All accessories MUST be connected external to furnace main casing.

DOWNFLOW FURNACES

Connect supply-air duct to supply-air opening on furnace. The supply-air duct attachment must ONLY be connected to furnace supply/outlet or

air conditioning coil casing (when used), when installed on non-combustible material. When installed on combustible material, supply-air duct

attachment must ONLY be connected to an accessory subbase or factory approved air conditioning coil casing. DO NOT cut main furnace casing

to attach supply side air duct, humidifier, or other accessories. All accessories MUST be connected external to furnace main casing.

HORIZONTAL FURNACES

Connect supply-air duct to supply air opening on furnace. The supply-air duct attachment must ONLY be connected to furnace supply/outlet or

air conditioning coil casing (when used). DO NOT cut main furnace casing to attach supply side air duct, humidifier, or other accessories. All

accessories MUST be connected external to furnace main casing.

D. Return Air Connections

UPFLOW FURNACES

The return-air duct must be connected to bottom, sides (left or right), or a combination of bottom and side(s) of main furnace casing. Bypass

humidifier may be attached into unused side return air portion of the furnace casing. DO NOT connect any portion of return-air duct to back of

furnace casing.

DOWNFLOW AND HORIZONTAL FURNACES

The return-air duct must be connected to return-air opening provided. DO NOT cut into casing sides or back to attach any portion of return-air

duct. Bypass humidifier connections should be made at ductwork or coil casing sides exterior to furnace.

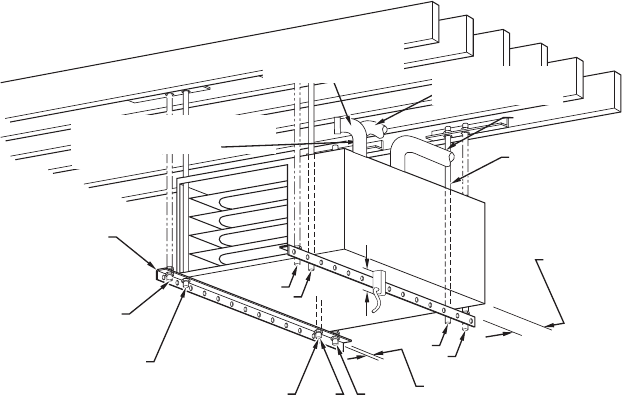

Fig. 22—Crawlspace Horizontal Application

A93304

NOTES:

ANGLE

IRON OR

EQUIVALENT

(B)

(A) ROD LOCATION

USING DIMPLE

LOCATORS

(SEE DIMENSIONAL

DWG FOR

LOCATIONS)

13

/16-IN. (21mm) MAX

ALTERNATE SUPPORT

LOCATION FROM BACK

ALTERNATE SUPPORT

LOCATION 4-IN. (102mm) MIN

8-IN. (203mm) MAX

3/8

-IN. (10mm) ROD

(A)

(B)

(A)

(B)

(B)

(A)

1. A 1 In. (25mm) clearance minimum between

top of furnace and combustible material.

2. The entire length of furnace must be

supported when furnace is used in horizontal

position to ensure proper drainage.

3. For non-direct vent/1-pipe application,

bottom side combustion-air entry cannot be

used when furnace is installed with hangers

as shown.

(A) PREFERRED ROD LOCATION

(B) ALTERNATE ROD LOCATION

DRAIN

5

3

/4

″ (146mm)

3

/8-IN. HEX NUT

& WASHER (4)

REQD PER ROD

VENT

COMBUSTION-AIR PIPE

(DIRECT VENT/2-PIPE

APPLICATION,ALL SIZES)

COMBUSTION-AIR INTAKE

(NON-DIRECT VENT/1-PIPE

APPLICATION)

3-IN. MINIMUM CLEARANCE TO

COMBUSTION-AIR INTAKE IS REQUIRED

(NON-DIRECT VENT/1-PIPE

APPLICATION,)

—21—