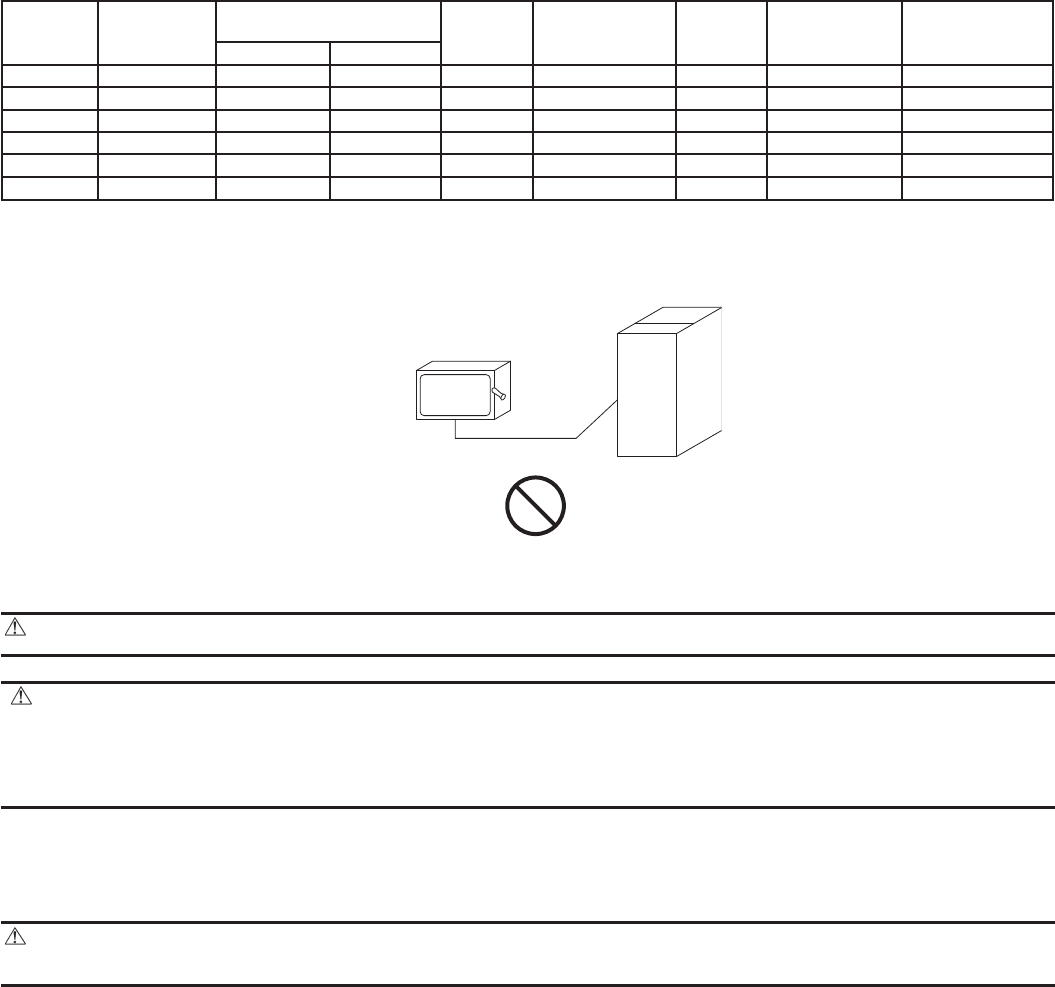

CAUTION: Do not connect aluminum wire between disconnect switch and furnace. Use only copper wire. (See Fig. 28.)

WARNING: The furnace casing MUST have an uninterrupted or unbroken ground according to NEC ANSI/NFPA

70-2002 and Canadian Electrical Code CSA C22.1 or local codes to minimize personal injury if an electrical fault should occur.

This may consist of electrical wire or conduit approved for electrical ground when installed in accordance with existing

electrical codes. Do not use gas piping as an electrical ground. Failure to follow this warning could result in electrical shock,

fire, or death.

J-BOX RELOCATION

1. Remove 2 screws holding auxiliary J-box. (See Fig. 29.)

2. Rotate J-box 180° and attach box to left side, using holes provided.

CAUTION: If manual disconnect switch is to be mounted on furnace, select a location where a drill or fastener will not

contact electrical or gas components.

B. 24-V Wiring

Make field 24-v thermostat connections at 24-v terminal block on control center. Y wire from thermostat MUST be connected to Y terminal on

control center, as shown in Fig. 27, for proper cooling operation. The 24-v terminal board is marked for easy connection of field wiring. (See Fig.

30.) The 24-v circuit contains a 3-amp, automotive-type fuse located on control center. (See Fig. 31.) Any electrical shorts of 24-v wiring during

installation, service, or maintenance may cause fuse to blow. If fuse replacement is required, use only a fuse of identical size (3 amp).

NOTE: Use AWG No. 18 color-coded copper thermostat wire for lengths up to 100 ft. For wire lengths over 100 ft, use AWG No. 16 wire.

NOTE: For 2-speed applications, refer to Sequence of Operation section.

C. Accessories

1. Electronic Air Cleaner (EAC)

The control center EAC terminals are energized with 115v (1.5-amp maximum) during blower operation.

a. Two extension leads are connected to the control center EAC terminals to assist field installation of an EAC. (See Fig. 31.) To use these

leads, proceed with the following:

(1.) Strip EAC power lead insulation approximately 1/4 in.

(2.) Insert stripped end into factory-supplied black lead’s butt connector and crimp to secure.

(3.) Strip EAC neutral lead insulation approximately 1/4 in.

(4.) Insert stripped end into factory-supplied white leads’s butt connector and crimp to secure.

Table 4—Electrical Data

UNIT

SIZE

VOLTS—

HERTZ—

PHASE

OPERATING

VOLTAGE RANGE

MAX

UNIT

AMPS

UNIT

AMPACITY†

MIN

WIRE

SIZE

MAX WIRE

LENGTH

(FT)‡

MAX FUSE

OR CKT BKR

AMPS**

Max* Min*

042040 115-60-1 127 104 8.9 12.0 14 31 15

042060 115-60-1 127 104 8.9 12.0 14 31 15

042080 115-60-1 127 104 8.9 12.0 14 31 15

060080 115-60-1 127 104 13.8 17.9 12 32 20

060100 115-60-1 127 104 13.8 18.1 12 32 20

060120 115-60-1 127 104 11.6 15.3 12 37 20

* Permissible limits of voltage range at which unit will operate satisfactorily.

† Unit ampacity = 125 percent of largest operating component’s full load amps plus 100 percent of all other potential operating components’ (EAC, humidifier, etc.) full load

amps.

‡ Length shown is a measured 1 way along wire path between unit and service panel for maximum 2 percent voltage drop.

** Time-delay type is recommended.

Fig. 28—Disconnect Switch and Furnace

A93033

COPPER

WIRE ONLY

ELECTRIC

DISCONNECT

SWITCH

ALUMINUM

WIRE

—26—