CAUTION: The entire length of furnace MUST be supported when furnace is used in a horizontal position to ensure

proper draining. When suspended, bottom brace supports sides and center blower shelf. When unit is supported from the

ground, blocks or pad should support sides and center blower shelf area.

PROCEDURE 4—AIR DUCTS

A. General Requirements

The duct system should be designed and sized according to accepted national standards such as those published by: Air Conditioning Contractors

Association (ACCA), Sheet Metal and Air Conditioning Contractors National Association (SMACNA) or American Society of Heating,

Refrigerating and Air Conditioning Engineers (ASHRAE), or consult The Air Systems Design Guidelines reference tables available from your

local distributor. The duct system should be sized to handle the required system design CFM at the design static pressure.

When a furnace is installed so that the supply ducts carry air to areas outside the space containing the furnace, the return air must also be handled

by a duct(s) sealed to the furnace casing and terminating outside the space containing the furnace.

Secure ductwork with proper fasteners for type of ductwork used. Seal supply- and return-duct connections to furnace with code approved tape

or duct sealer.

Flexible connections should be used between ductwork and furnace to prevent transmission of vibration. Ductwork passing through unconditioned

space should be insulated to enhance system performance. When air conditioning is used, a vapor barrier is recommended.

Fig. 20—Furnace, Plenum, and Coil Assembly or

Coil Box Installed on a Combustible Floor

A96284

CD5 OR CK5

COIL ASSEMBLY

OR KCAKC

COIL BOX

FURNACE

SHEET METAL

PLENUM

FLOOR

OPENING

COMBUSTIBLE

FLOORING

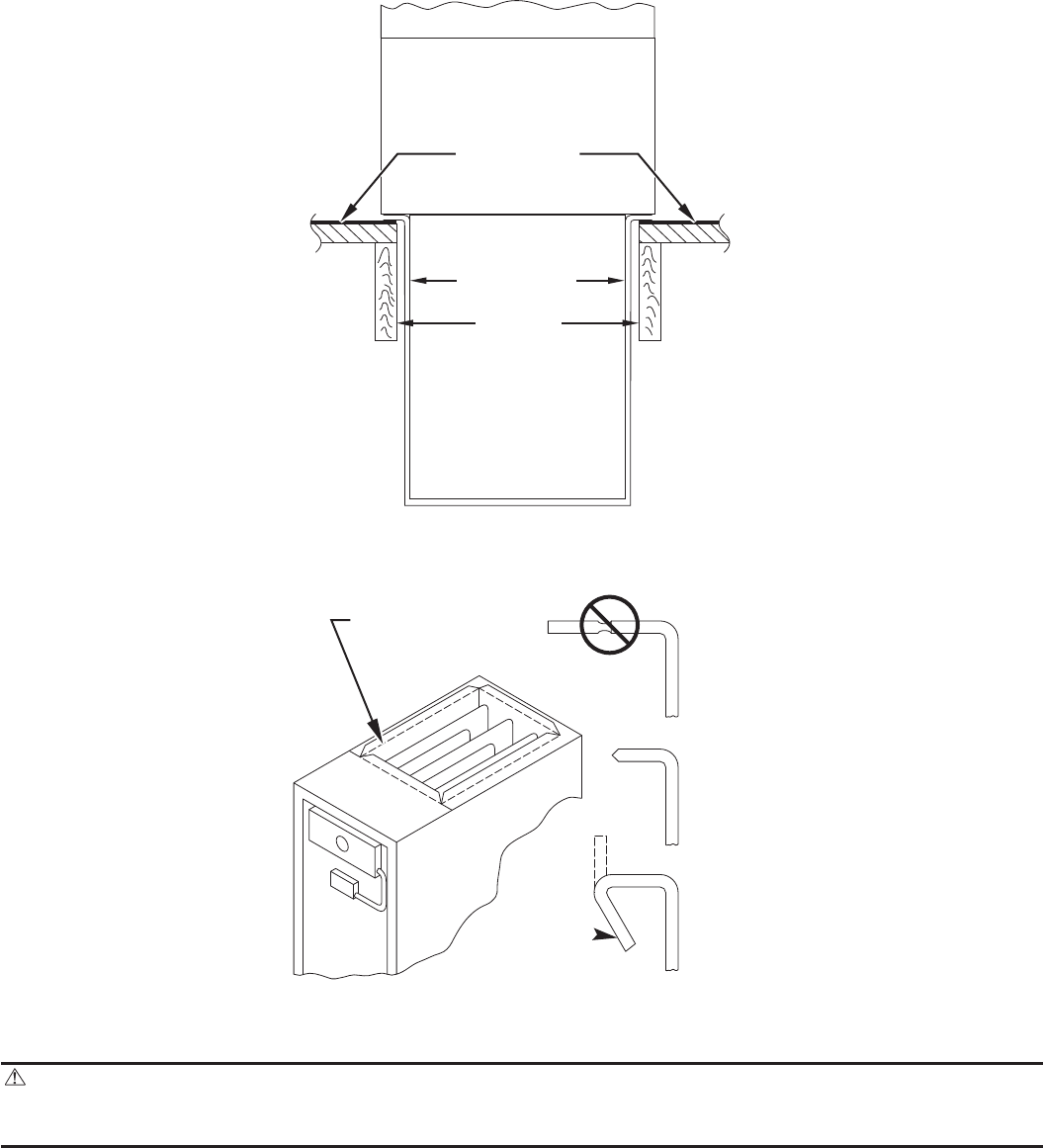

Fig. 21—Duct Flanges

A93029

NO

YES

YES

PERFORATED

DISCHARGE DUCT

FLANGE

210 DEG.

MIN

—20—