AZI Customer Service 800-528-7411 or 602-470-1414 Page 68 of 92

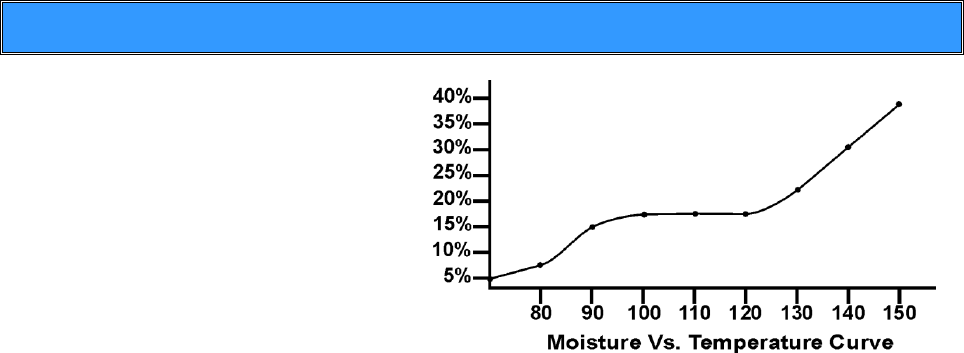

7.2. Determining Proper Test Temperature

If the moisture of the sample material

is known, as determined by a

reference method, the MAX 5000XL's

temperature can be adjusted until test

results correlate with the established

moisture concentration. If the

moisture is not known, prepare a

moisture versus temperature curve to

decide the proper test temperature for

a particular sample.

An appropriate curve can be prepared by testing sample material at increasing

temperatures of five-degree increments.

The starting temperature is usually the standard or reference method temperature for that

particular sample. Results for each increasing temperature will usually rise to a plateau

where several temperature increases do not change the results significantly. Beyond this

plateau, results can rise dramatically. Examination of a sample, tested at these increased

temperatures, may show burning or charring.

Results along the plateau usually correlate well with the standard or reference method

results. Repeated testing should be done at temperatures in this range. Several tests are

performed using the same sample size and test parameters. Results from these repeated

tests are tabulated to calculate the mean, or average, and the standard deviation (S.D.).

Analysis of the mean and standard deviation, and their comparison with reference

method results, determines if the proper test temperature has been used. If mean values

do not compare well, or if the standard deviation is too large, test at another temperature

along the plateau.