AZI Customer Service 800-528-7411 or 602-470-1414 Page 67 of 92

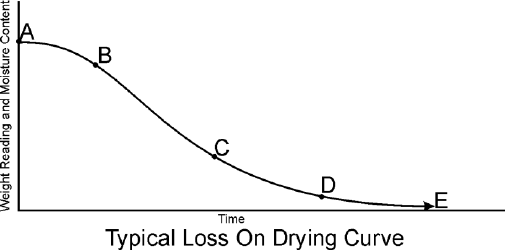

A typical drying curve is shown at the

right.

Section (A-B) represents the sample's

weight loss as it heats from room to

testing temperature.

Section (B-C) is linear, representing

moisture loss from the interior of each

particle of the tested sample.

Section (C-D) is exponential in nature

and represents the final evolution of moisture from within the particle. The point at which

no additional weight loss occurs represents the complete evolution of water from the

original sample (E).

Section (D-E) is the longest and most time-consuming portion of the entire testing

process. The time for a sample to reach zero residual moisture in an oven can take from

one to possibly 24 hours depending upon the sample, sample preparation, and testing

temperature. The MAX 5000XL loss-on-drying system calculates the sample's moisture

concentration through mathematical extrapolation from the exponential (C-D) portion of

the curve.

An aluminum pan sits on a pan support coupled to a sensitive electronic force balance.

The force balance registers the initial weight of the sample before testing and relays the

sample's decreasing weight to the microprocessor for evaluation. Balance readings are

averaged to eliminate signal interference or erroneous data.

Within each memory start, test temperatures can be programmed between normal room

temperature (25º

C) and 600º

C in either a one-step or multi-step temperature contour.

A heater is located on the underside of the test chamber's lid. An RTD monitors the

temperature of the test chamber and sends that information back to the microprocessor.

Under the microprocessor's control, the heater element is cycled on and off to bring the

test chamber to the programmed level.

During the entire testing process, the microprocessor monitors the sample's weight loss.

The sample's decreasing weight is compared to the initial sample weight and the

calculated moisture concentration will appear on the display. Simultaneously, the

microprocessor is predicting a final moisture concentration based upon the sample's rate

of weight loss compared to the exponential portion of a standard drying curve. Testing

will continue until the predicted moisture concentration agrees within a certain percentage

of the actual moisture concentration appearing on the display. The percent agreement

between the predicted and the actual moisture concentrations will vary depending upon

the system's programming and the moisture level of the sample.

The MAX 5000XL is an extremely flexible instrument. This flexibility means that some

time is required to determine the best set of parameters for a particular application. The

determination of the proper parameters requires a series of tests, and good laboratory

procedure. Call your AZI technical sales representative at 800-528-7411 or

602-470-1414 for assistance.