Theory of Operation Teledyne API – Model T300/T300M CO Analyzer

Teledyne Analytical Instruments 294

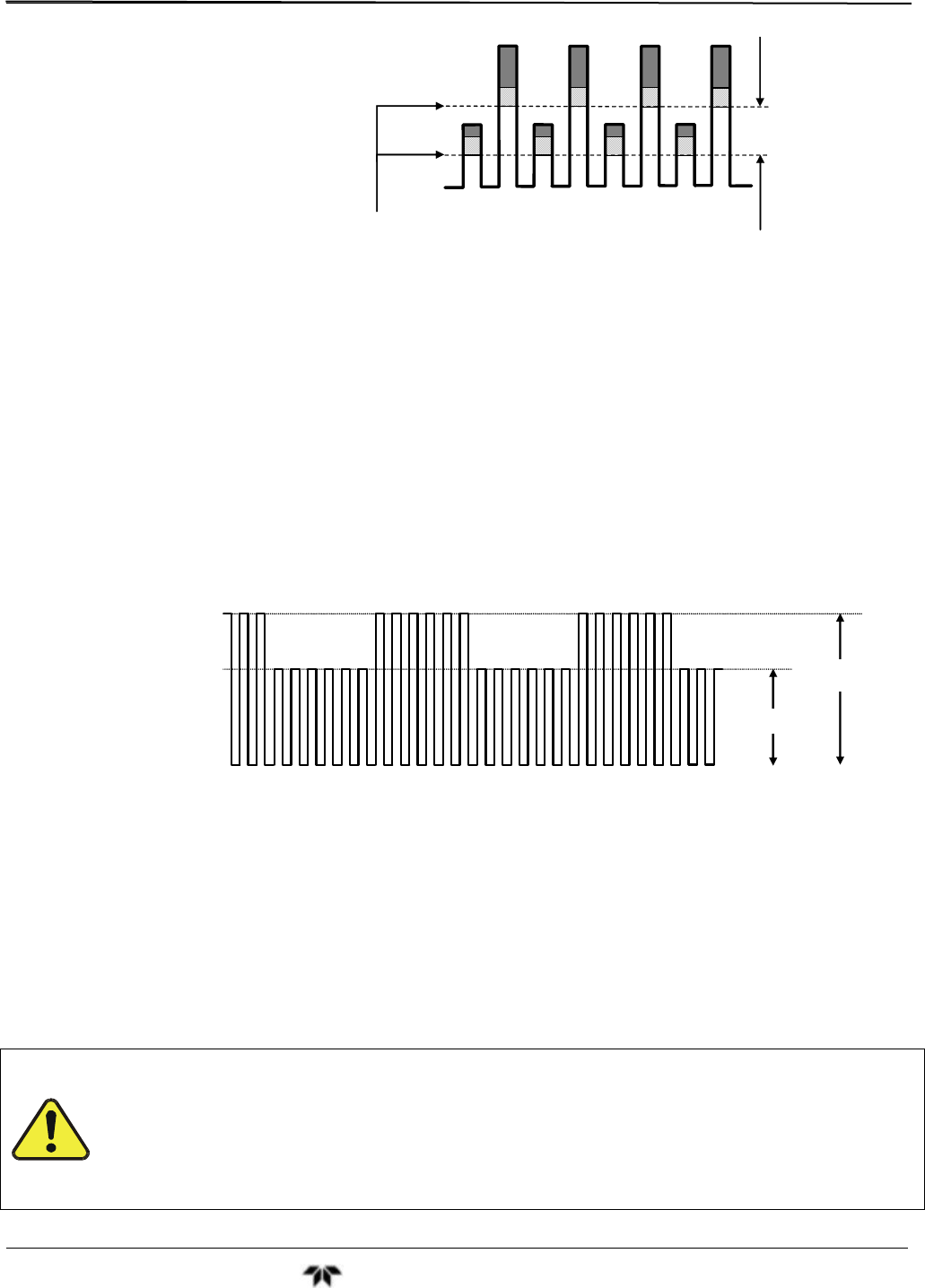

IR shining through both cells is

affected equally by interfering

gas in the Sample Chamber

M/R

is Shifted

Figure 13-5: Effects of Interfering Gas on CO MEAS & CO REF

Thus, the difference in the peak heights and the resulting M/R ratio is only due to CO

and not to interfering gases. In this case, GFC rejects the effects of interfering gases and

so that the analyzer responds only to the presence of CO.

To improve the signal-to-noise performance of the IR photo-detector, the GFC Wheel

also incorporates an optical mask that chops the IR beam into alternating pulses of light

and dark at six times the frequency of the measure/reference signal. This limits the

detection bandwidth helping to reject interfering signals from outside this bandwidth

improving the signal to noise ratio.

The IR Signal as the Photo-

Detector sees it after being

chopped by the GFC Wheel

S

CO REF

CO MEAS

Figure 13-6: Chopped IR Signal

13.2.1.3. SUMMARY INTERFERENCE REJECTION

The basic design of the GFC7001T/GFC7001TM rejects most of this interference at a

300:1 ratio. The two primary methods used to accomplish this are:

The 4.7μm band pass filter just before the IR sensor which allows the

instrument to only react to IR absorption in the wavelength affected by CO.

Comparison of the measure and reference signals and extraction of the ratio

between them.

Pneumatic Operation

CAUTION – GENERAL SAFETY HAZARD

It is important that the sample airflow system is both leak tight and not pressurized

over ambient pressure.

Regular leak checks should be performed on the analyzer as described in the

maintenance schedule, Table 11-1.

Procedures for correctly performing leak checks can be found in Section 11.3.2.