44

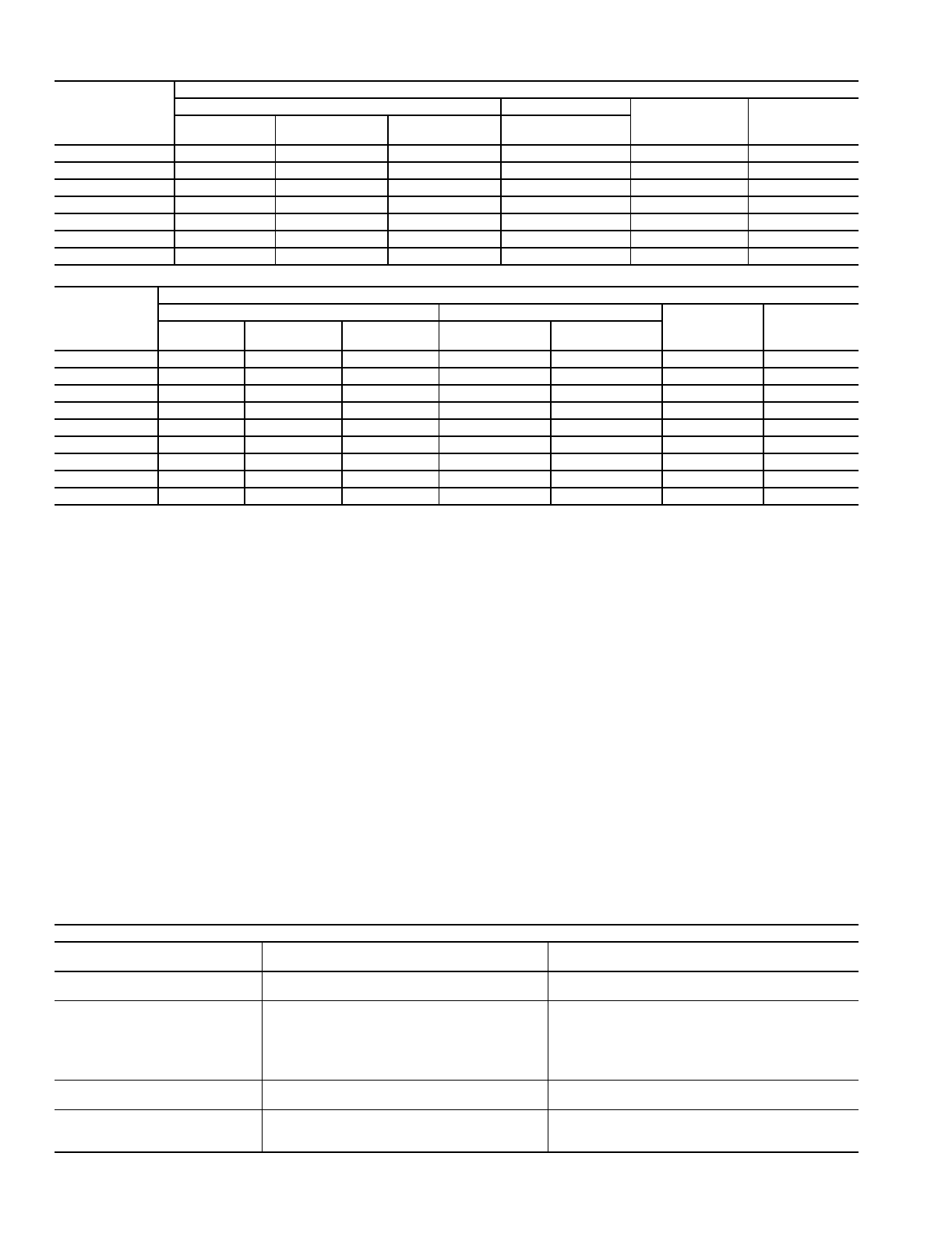

Table 20 — Compressor Loading and Unloading Sequences (cont)

TROUBLESHOOTING

By using the display module, actual operating conditions of

the unit are displayed while it is running. The Quick Test func-

tion allows proper operation of compressors, compressor un-

loaders, fans, and other components to be checked while unit is

stopped. If an operating fault is detected, an alarm is generated

and an alarm code(s) is displayed. For checking specific items,

see Table 21.

Checking Display Codes —

To view the digital dis-

play codes, press the button located to the right of the LED dis-

play/set point board in the control box. See Table 22 for Opera-

tional Status Codes. See Table 23 for Diagnostic Codes.

Complete Unit Stoppage —

If the unit is off, there are

several conditions that can cause this situation to occur:

• Remote ON/OFF circuit in Unoccupied mode.

• Unit ON/OFF switch moved to OFF position.

• Programmed schedule at the timeclock.

• General power failure.

• Blown fuse in the control power feed.

• Open control circuit fuse.

• Operation of the unit blocked by the demand limit

function.

• Unit supply-air temperature (T1) thermistor failure.

• Supply-air fan is not operating.

• High duct static pressure.

Single Circuit Stoppage —

If a single circuit stops,

there are several potential causes:

• Open contacts in the compressor high-pressure switch.

• Low refrigerant pressure.

• Thermistor failure.

• Unit supply-air temperature thermistor (T1) failure.

• Compressor circuit breaker trip.

• Operation of the circuit blocked by the demand limit

function.

Table 21 — Controls Troubleshooting

COOLING

STAGE

SIZE 088 UNITS

Lead Circuit Lag Circuit

Active

Cylinders

Percent

Capacity

Comp 1

Unloader

U1

Unloader

U2

Comp 2

0

OFF OFF OFF OFF 0 0

1

ON ON ON OFF 2 16

2

ON ON OFF OFF 4 33

3

ON OFF OFF OFF 6 50

4

ON ON ON ON 8 66

5

ON ON OFF ON 10 83

6

ON OFF OFF ON 12 100

COOLING

STAGE

SIZE 104 UNITS

Lead Circuit Lag Circuit

Active

Cylinders

Percent

Capacity

Comp 1

Unloader

U1

Comp 3 Comp 2 Comp 4

0

OFF OFF OFF OFF OFF 0 0

1

ON ON OFF OFF OFF 4 20

2

ON OFF OFF OFF OFF 6 30

3

ON ON OFF ON OFF 10 50

4

ON OFF OFF ON OFF 12 60

5

ON ON OFF ON ON 14 70

6

ON OFF OFF ON ON 16 80

7

ON ON ON ON ON 18 90

8

ON OFF ON ON ON 20 100

SYMPTOM(S) PROBABLE CAUSE(S) SOLUTION(S)

Controls do not seem

to be operating.

Remote on-off function may be

keeping controls off.

Check status.

Evaporator fan does not run.

1. Circuit breaker open.

2. Inverter overload (if equipped).

1. Find cause and reset circuit breaker.

2. Find cause and reset.

Compressor does not run.

1. Circuit breaker is open.

2. There is no demand for cooling.

3. The control is locking out cooling operation.

4. Demand Limit in effect.

1. Find cause and reset circuit breaker.

2. Correct operation.

3. Check rotating display for alarm codes. Resolve

alarm cause and reset control by changing to

standby and back to run mode.

4. Check Demand Limit Settings.

Condenser fans do not

turn on.

Circuit breaker is open. Find cause and reset circuit breaker

Cooling demand exists and

economizer modulates, but

compression is not operating.

Compression cannot be initiated

until economizer damper is 90% open.

Correct operation.