57

POWER EXHAUST VFD OPERATION — When trouble-

shooting the power exhaust VFD, check first that all required

conditions for power exhaust VFD operation are satisfied.

For the power exhaust VFD to run, the following conditions

must be met at the power exhaust VFD:

1. Drive enable jumper is installed from terminals ST-CC

(factory supplied) (see Fig. 56).

2. Proper rotation jumper is installed at terminals R-CC (re-

verse rotation, factory supplied).

3. Emergency stop jumper is installed from terminals

S4-CC (factory supplied).

4. A 4 to 20 mA signal is applied across terminals IV-P24

(from pressure transducer, factory supplied).

5. DIP switch SW1 (located on the VFD’s printed circuit

control panel) must be set to “I” (indicating usage of a 4

to 20 mA input signal at terminals “IV”).

6. Speed Control (located on the VFD’s keypad/display) set

for “Remote” (press the “Speed Ctrl” button until LED

“Remote” is illuminated).

7. Programmed according to Carrier defaults.

8. Building Pressure set point established by user, or

use factory default (30 Hz indicating 0.0 in. wg) (see

Table 15).

POWER EXHAUST VFD OPERATIONAL STATUS —

The power exhaust VFDs contain extensive self-diagnostic

functions which are accessed through the power exhaust VFD

display panel (located on the front of the power exhaust VFD

or at a remote location when the accessory remote display

package has been installed.)

When power is first supplied to the power exhaust VFD, the

display automatically starts with the frequency monitor func-

tion of its standard monitor mode. In the frequency monitor

function, the output frequency is displayed. Push the S/P/M

(Setup/Program/Monitor) key to switch to the Mode Selec-

tion menu. Push the S/P/M

key again to toggle the display

back to the standard monitor mode.

From the Mode Selection menu, the service person can

view all of the monitored status variables, including up to four

user-selected variables and any trip history in the memory.

Refer to the separate VFD Operation Manual for detailed

instructions on accessing diagnostic information, initiating

troubleshooting, and clearing any trip history.

RESTORING FACTORY POWER EXHAUST VFD

DEFAULTS — The original factory configuration values are

saved in the memory of the power exhaust VFD and can be

restored by the service person if required. There are two types

of saved file data: Carrier-factory settings (factory pro-

grammed settings made to the power exhaust VFD which

apply specifically to the unit it is installed on) and standard

defaults for general Carrier unit use.

The Carrier-factory settings are maintained as user settings.

These can be restored by entering the Setup mode (in the

S/P/M menu) and setting parameter tYP = 6 on the keypad/dis-

play. This will recall the specific factory defaults for this unit.

Occasionally it may be necessary to restore the power ex-

haust VFD defaults to the general Carrier use values. These are

stored in an OPTION ROM (read-only memory chip). Howev-

er, some variables may need to be manually changed to match

the specific unit’s factory default settings. To recall the general

Carrier defaults, enter the Setup mode and set parameter

tYP = 3. Refer to Tables 34 and 35 for items requiring manual

adjustment.

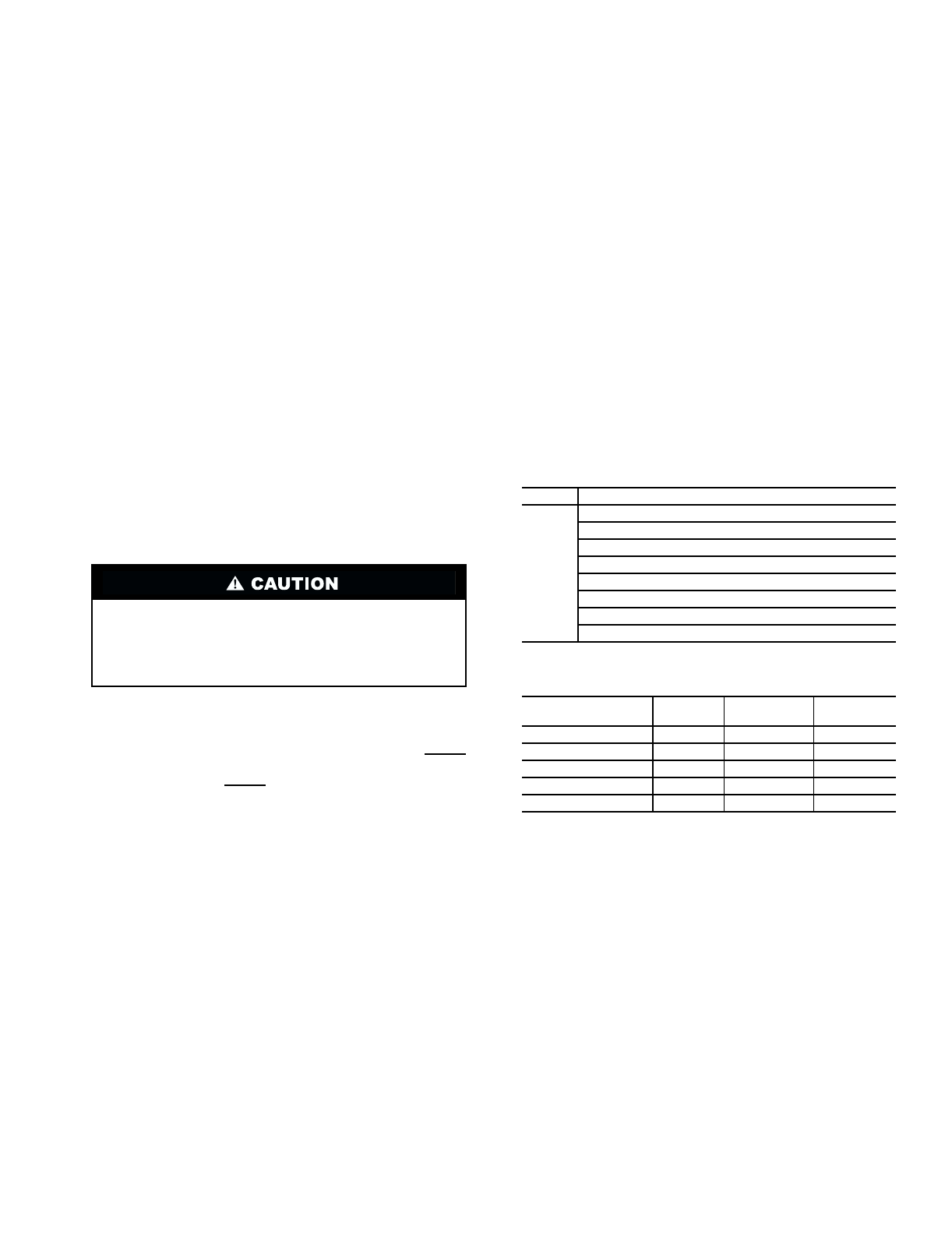

Table 34 — Power Exhaust VFD Required

User Adjusted Defaults

Table 35 — Power Exhaust Motor

Overload Settings

Unit Wiring —

A typical wiring schematic is shown in

Fig. 57.

If using the VFD display panel, disconnect all power to

the unit and the VFD before entering unit, or use the

accessory remote display module. Disable supply fan and

motor operation before accessing VFD-mounted display

module.

UNIT ITEM

ALL

Motor Overload Settings (See Table 35)

Gr.St/Ot1 = 4

Gr.St/Ot2 = 2

Gr.St/Ot2d = 5

Gr.St/Ot2H = 100

Gr.St/LF = 15

SEtP/UL = 59.8

SEtP/P4 = 98

MODEL NUMBER

POSITION 16

TOTAL

HP

MOTOR HP

(ea)

tHr1

SETTING

H, T

20 10 97.3

J, V

30 15 100.0

K, W

40 20 100.0

L, X

50 25 93.5

M, Y

60 30 92.3