7

Compressor Operation

CONTROL RELAY (CR) — This relay provides information

to the processor about compressor operation (one control relay

per compressor). The relay controls and protects the compres-

sor and also controls the crankcase heater.

A control signal to check the safety statuses and to start the

compressor is sent from the relay board. This signal travels

through all of the safeties: the high-pressure switch, and the in-

ternal protector (where used) and on to the control relay coil.

Once the control relay coil has been energized, the control re-

lay completes a feedback circuit for the processor, informs the

processor of the status of the compressor safeties, energizes the

compressor contactor coil, and deenergizes the crankcase heat-

ers. A fault will be detected by the processor if the control relay

opens during operation or startup. The processor will lock the

compressor or the circuit off by deenergizing the appropriate

relay(s) on the relay board and energizing an alarm signal.

Accessory Board —

The accessory board is standard

(factory supplied) in the VAV rooftop units. See Fig. 15. This

board is located in the control box of each unit. Each board has

a prewired connector supplied with it to connect directly to the

processor board. It has 3 potentiometers: P3, P5, and P6.

P3 — RESET LIMIT — The processor board is programmed

for occupied space temperature reset. In order for reset to

work, the accessory temperature reset board must be used.

Potentiometer P3 is the maximum set point temperature to

which the supply air can be reset.

P5 — ECONOMIZER MINIMUM POSITION — This

potentiometer controls the set point for the minimum position

of the economizer.

P6 — MORNING WARM-UP TEMPERATURE — This

potentiometer controls the morning warm-up temperature set

point.

Single-Step Demand Limit —

The single step de-

mand limit provides a means to limit the capacity of the VAV

unit using an external switch. Single step demand limit will

limit the compressor displacement based on the ratio of the

wiper arm to the full scale resistance. The exact percentage of

capacity reduction differs depending on the number of capacity

steps.

A 3-wire, 5 to 20 Kohm, field-supplied potentiometer (P4)

is required for this option. The potentiometer should be wired

to the processor J3 connections. In order to control the demand

limit, the wiper arm of the potentiometer should be switched

open and closed based on the demand limit requirement. The

control switch is also field-supplied and installed.

If the wiper arm wire is open, all capacity stages can be

used. When the wiper arm wire is closed, the capacity is re-

duced by the amount set on potentiometer P4.

Demand Limit Control Module (DLCM) —

The

DLCM provides a 2-step demand limit control using an exter-

nal switch. The first step is between 50% and 100% of the

maximum compressor displacement. See Fig. 16. The second

step is between 0% and 49% of the maximum compressor dis-

placement. The exact percentage differs depending on the

number of capacity steps.

Two adjustable potentiometers are used to set the 2 demand

limit points. Potentiometer P1 is used to set a demand limit

between 50% and 100% of the unit capacity. Potentiometer P2

is used to set a demand limit between 0% and 49% of unit

capacity.

If no power is supplied to the demand limit control module,

all capacity stages can be used. When power is supplied to ter-

minal IN1 only, the first step of the demand limit control is en-

ergized and the capacity is reduced by the amount set on poten-

tiometer P1. When power is supplied to terminal IN2 only, or

to both IN1 and IN2, the capacity is reduced by the amount set

on potentiometer P2.

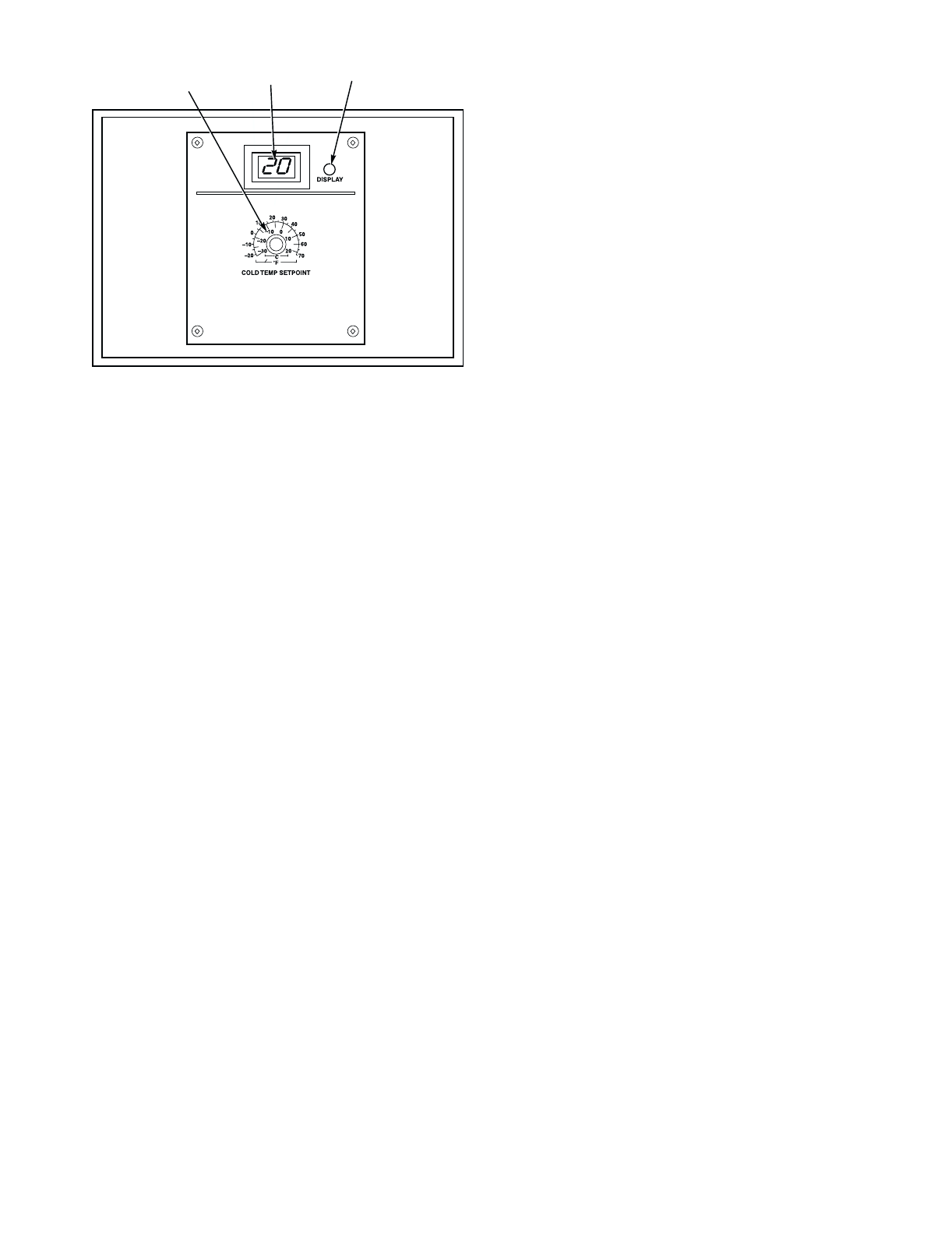

TWO-DIGIT

DISPLAY

DISPLAY

BUTTON

P1 SUPPLY AIR

SET POINT

POTENTIMETER

Fig. 6 — Display/Set Point Board