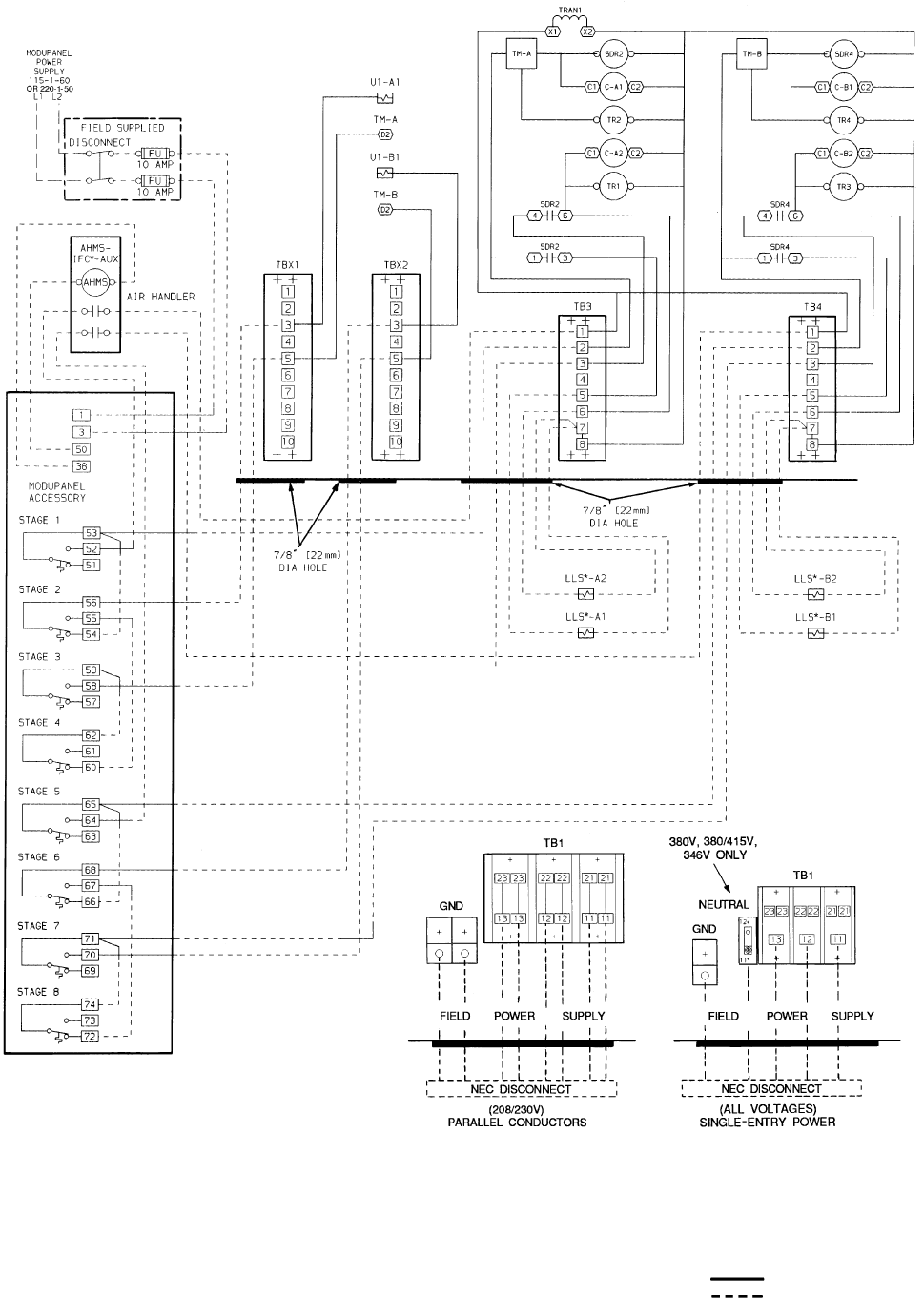

*Field-supplied.

NOTES:

1. Factory wiring is in accordance with NEC. Field modifications or

additions must be in compliance with all applicable codes.

2. Wiring for field power supply must be rated 75 C minimum. Use

copper, copper-clad aluminum, or aluminum conductors. Maxi-

mum incoming wire size for each terminal block is 500 kcmil.

3. Terminal blocks TB3, TB4, TBX1, and TBX2 are for external field

control connections. Control connections are to be Class 1 wiring.

4. Field-supplied components (IFC, LLS-A1, A2, B1, and B2) must

have a maximum sealed coil rating of 30 va each (0.25 amp at

120vac, 0.13amp at230 vac).AHMSIFC-AUX contactmusthave

minimum pilot duty rating of 375 va each (3.1 amps at 120 vac,

1.6 amps at 230 vac).

5. Replacement of factory wires must be with type 105 C wire or its

equivalent.

6. Field-supplied liquid line solenoid valves installed at the evapora-

tor are required on all units.

7. Controlhas35va ofpoweravailablefor field-installedaccessories.

LEGEND

AHMS — Air Handler Motor Starter

AUX — Auxiliary

C—Compressor Contactor

FU — Fuse

GND — Equipment Ground

IFC — Indoor Fan Control

kcmil — Thousand Circular Mils

LLS — Liquid Line Solenoid

NEC — National Electrical Code

(U.S.A. Standard)

SDR — Solenoid Drop Relay

TB — Terminal Block

TBX — Terminal Block for

Variable Air Volume

Units

TM — Timer Motor

TR — Timer Relay

TRAN — Transformer

U—Unloader Solenoid

Factory Wiring

Field Wiring

Fig. 27 — Field Wiring, Single ModuPanel™ Control, Unit 38AH104

35