Step 3 — Make Refrigerant Piping

Connections

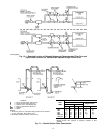

The field-supplied liquid line solenoid valve must be

installed at the evaporator to avoid possible compressor

damage during unit operation. See Fig. 11 (for 38AH044-

084 dual-circuit and 38AH094-134 units), or Fig. 12 (for

38AH044-084 optional single-circuit units).

The units have large suction lines to minimize friction losses.

The units also have the ability to operate at low capacity.

Because of these capabilities, use special care with suction

piping and suction risers to ensure proper compressor oil

return under all operating conditions. Maximum allowable

vertical separation between the condensing unit and the evapo-

rator is shown in Table 5. Size suction lines in accordance

with Tables 6A or 6B through 9A or 9B and Fig. 13. Mount

liquid line solenoid valve just ahead of the TXVs (thermo-

static expansion valves) which will be mounted at the

evaporator. See Fig. 11 (for 38AH044-084 dual-circuit and

38AH094-134 units) or Fig. 12 (for 38AH044-084 optional

single-circuit units).

To achieve good mixing of the refrigerant leaving the evapo-

rator suction header for proper sensing by the TXV bulb:

1. Install a minimum of two 90-degree elbows upstream of

the TXV bulb location. See Fig. 14 (for 38AH044-084

dual-circuit and 38AH094-134 units) or Fig. 15 (for

38AH044-084 optional single-circuit units).

2. Locate the TXV bulb on a vertical riser, where possible.

If a horizontal location is necessary, secure the bulb at

approximately the 4 o’clock position.

3. Size the suction line from the evaporator to the common

suction line to achieve high refrigerant velocity. See

Tables 6A or 6B through 9A or 9B and Fig. 13.

If an oil return connection at the bottom of the suction

header is supplied with an evaporator, tee-in this connection

ahead of first mixing elbow. See Fig. 14 (for 38AH044-084

dual-circuit and 38AH094-134 units) or Fig. 15 (for 38AH044-

084 optional single-circuit units). When the compressor is

below the evaporator, the riser at the evaporator should ex-

tend to the top of the evaporator section. After the riser is

installed, the suction line can elbow down immediately.

Install a field-supplied filter drier and sight glasses in each

refrigerant system. Select the filter drier for maximum unit

capacity and minimum pressure drop.Figure 11(for 38AH044-

084 dual-circuit and 38AH094-134 units) or Fig. 12 (for

38AH044-084 optional single-circuit units) shows required

location of solenoid valves and recommended locations for

the filter driers and sight glasses. Complete the refrigerant

piping from the evaporator to the condenser before opening

the liquid and suction lines at the condenser.

Table 5 — Liquid Lift

UNIT

38AH

MAXIMUM LIQUID LIFT

60 Hz 50 Hz

FtMFtM

044 69 21.0 57.5 17.5

054 75 23.0 75.0 23.0

064 75 23.0 65.0 19.8

074 45 13.7 37.5 11.4

084 75 23.0 75.0 23.0

094 55 16.7 46.0 14.0

104 50 15.2 42.0 12.8

124 75 23.0 65.0 19.8

134 45 13.7 37.5 11.4

UNITS 38AH044-084 — Relieve the pressure caused by the

holding charge into a refrigerant recovery system. Uncap

the suction line and cut the run-around tube at the liquid line

as close to the loop elbow as possible. This will leave

approximately 2 in. (50 mm) of straight tube for liquid line

connection.

IMPORTANT: Protect the liquid valves from the heat

of brazing.

Leak test the entire system by using soap bubbles and

nitrogen or R-22 with an electronic leak detector.

Purge nitrogen or reclaim R-22 from system after com-

pletion of leak-checking procedure. Repair leak if one is

found. When finished, evacuate and dehydrate system using

the methods described in Carrier GTAC II (General Training

Air Conditioning II), Module 4, System Dehydration.

UNITS 38AH094-134 — Relieve the R-22 holding charge

of each circuit into a refrigerant recovery system. Remove

the liquid line to factory-installed suction line loop by cut-

ting the loop at the liquid valve. (See Fig. 9A and 9B.) Cut

as close to the 90-degree bend in the loop as possible. The

remaining tube piece in the valve will be used for brazing

the liquid line. Unbraze and remove the cap from the liquid

line. For 38AH094 and 104 units, sweat-connect the liquid

and suction lines from the evaporator. For 38AH124 and 134

units, see Piping Kit Connections on page 21.

LEGEND

LLS — Liquid Line Solenoid

TXV — Thermostatic Expansion Valve

*Field-Supplied.

Fig. 11 — Required Location of Solenoid Valves and Recommended Filter Drier and

Sight Glass Locations for 38AH044-084 Dual-Circuit and 38AH094-134 Units

14