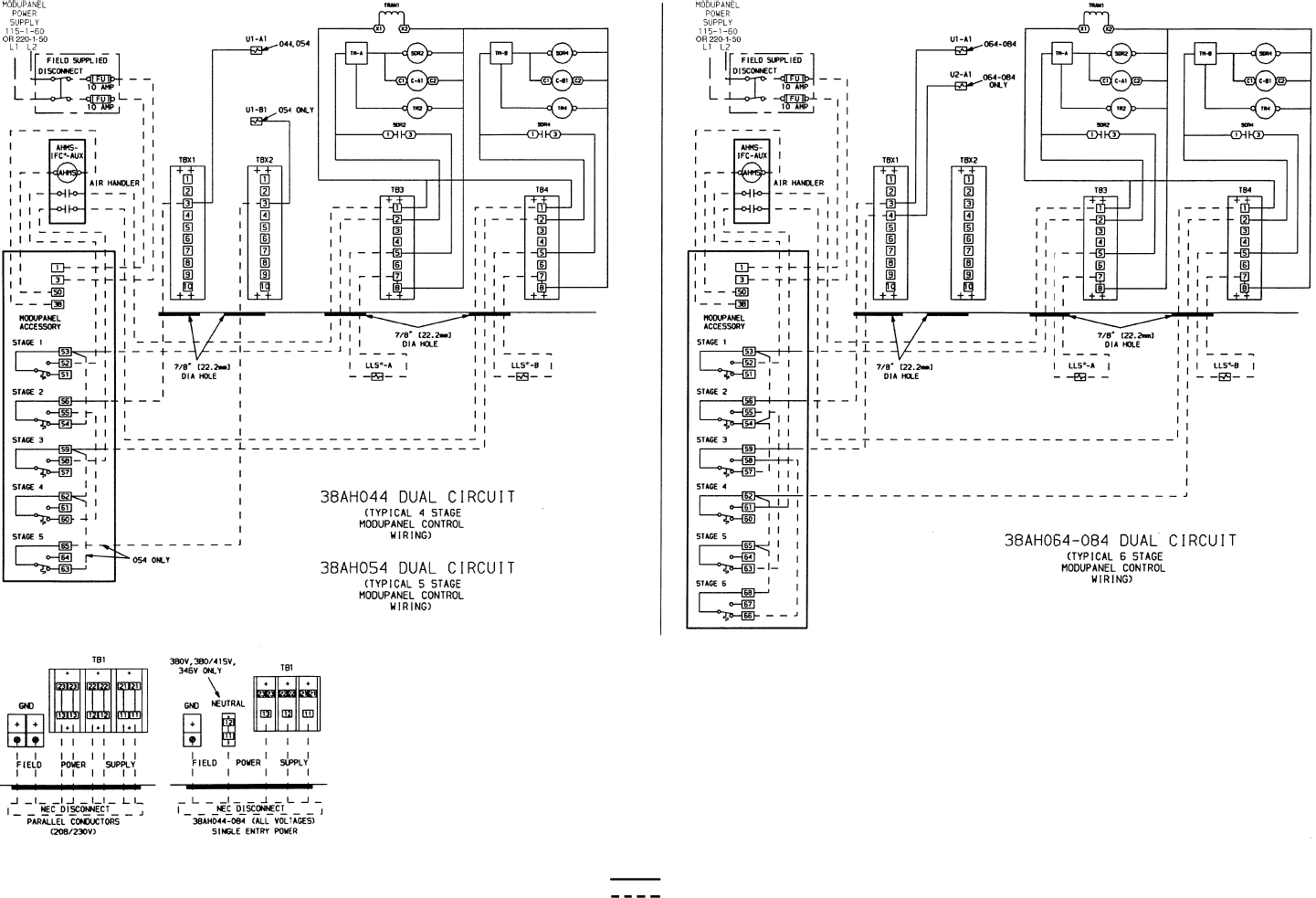

*Field-supplied.

NOTES:

1. Factory wiring is in accordance with NEC; field modifications or addi-

tions must be in compliance with all applicable codes.

2. Wiring for field power supply must be rated 75 C minimum. Use cop-

per, copper-clad aluminum, or aluminum conductors. Maximum

incoming wire size for each terminal block is 500 kcmil.

3. Terminal blocks TB3 and TB4 are for external field control connec-

tions. Control connections are to be Class 1 wiring.

4. Field-suppliedcomponents(IFC,LLS-A,andLLS-B) musthaveamaxi-

mum sealed coil rating of 30 va each (.25 amp at 120 vac, .13 amp at

230 vac). AHMS IFC-AUX must have a minimum pilot duty rating of

200 va (1.7 amps at 120 vac, 0.9 amps at 230 vac) each.

5. Replacement of factory wires must be with type 105 C wire or its

equivalent.

6. Field-suppliedliquidlinesolenoidvalves installedattheevaporator are

required on all units.

7. Units have 175 va of power available for field-installed accessories.

Fig. 24 — Field Wiring, Single ModuPanel™ Control, 38AH044-084 Dual-Circuit Units

LEGEND

AHMS — Air Handler Motor

Starter

AUX — Auxiliary

C—Compressor Contactor

FU — Fuse

GND — Equipment Ground

IFC — Indoor Fan Control

kcmil — Thousand Circular Mils

LLS — Liquid Line Solenoid

NEC — National Electrical Code

(U.S.A. Standard)

SDR — Solenoid Drop Relay

TB — Terminal Block

TBX — Terminal Block for Variable

Air Volume Units

TM — Timer Motor

TR — Timer Relay

TRAN — Transformer

U—Unloader Solenoid

Factory Wiring

Field Wiring

32