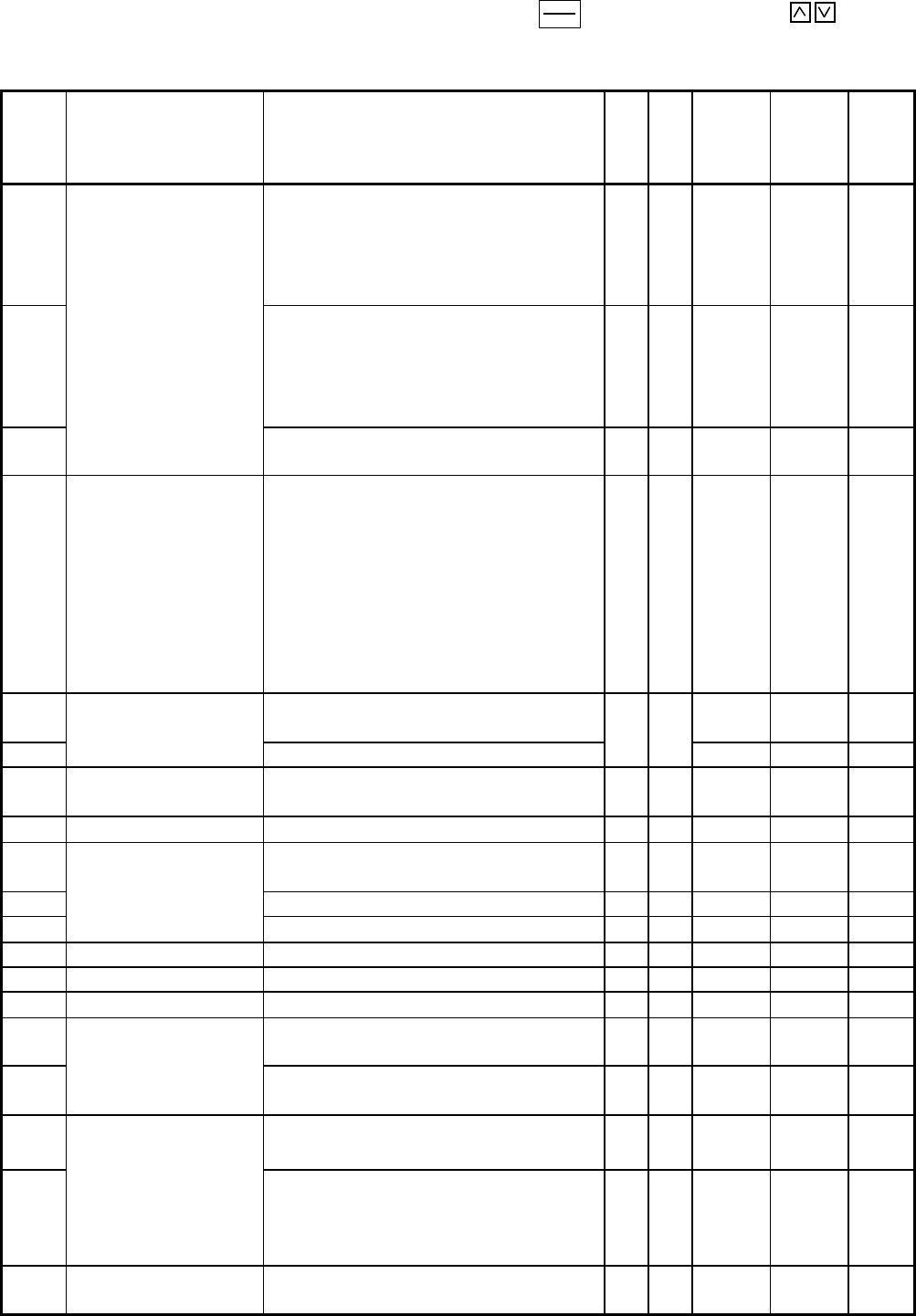

Change during operation: N = impossible, Y* = possible (enabled by using ),

Y

= possible (enabled by using

)

-

34

-

FUNC

DATA

Func-

tion

code

No.

Name Setting range

Unit

Min.

unit

Factory

setting

Change

during

operation

User

setting

F10

Electronic thermal

overload relay (Select)

0:Inactive

1:Active

(for 4-pole standard motor)

2:Active

(for 4-pole forced air motor)

-

-

1 Y*

F11

(Level) 20 to 135% of drive rated current

A 0.01

Typical

value of

GE 4-

pole

motor

Y*

F12

(Thermal time constant)

0.5 to 10.0min

min 0.1 5.0 Y*

F14

Restart after mo-

mentary power failure

0:Inactive (Trip and alarm when

power failure occurs)

1:Inactive (Trip and alarm when

power recovers)

2:Active (Momentarily stops and

restarts at setting frequency of

before power failure)

3:Active (Momentarily stops and

restarts at starting frequency)

-

-

0

N

F15

Frequency limiter

(High)

0 to 120Hz

70 Y

F16

(Low) 0 to 120Hz

Hz 1

0 Y

F17

Gain (for frequency

setting signal)

0: For 0 to +10Vdc,

1: For 0 to +5Vdc

-

-

0

N

F18

Bias frequency -120 to 120Hz

Hz 1 0 Y

F20

DC injection brake

(Starting freq.)

Fixed to 3Hz

Hz

-

3.0

-

F21

(Braking level) 0 to 100%

% 1 0 Y

F22

(Braking time) 0.0 s (Inactive), 0.1 to 30.0 s

s 0.1 0.0 Y

F23

Starting frequency 1 to 6Hz

Hz 1 1

N

F24

-

Data cannot be changed.

-

-

0.0

-

F25

Stop frequency 1 to 6Hz

Hz 1 1

N

F26

0 to 15kHz

0.75kHz is set when 0 is specified

kHz 1 2 Y

F27

Motor sound

(carrier freq.)

(sound tone )

0: Level 0 1: Level 1

2: Level 2 3: Level 3

-

-

0 Y

F30 FM terminal

(Voltage adjust)

0 to 200%

% 1 100

Y

F31

(Function) 0: Output frequency

1: Output current

2: PID feedback amount

3: DC link circuit voltage

-

-

0 Y*

F36

30Ry operation mode 0: Excited when tripped

1: Normally excited

-

-

0

N