Instruction Manual

IM-106-5500, Original Issue

August 2005

CCO 5500

2-10

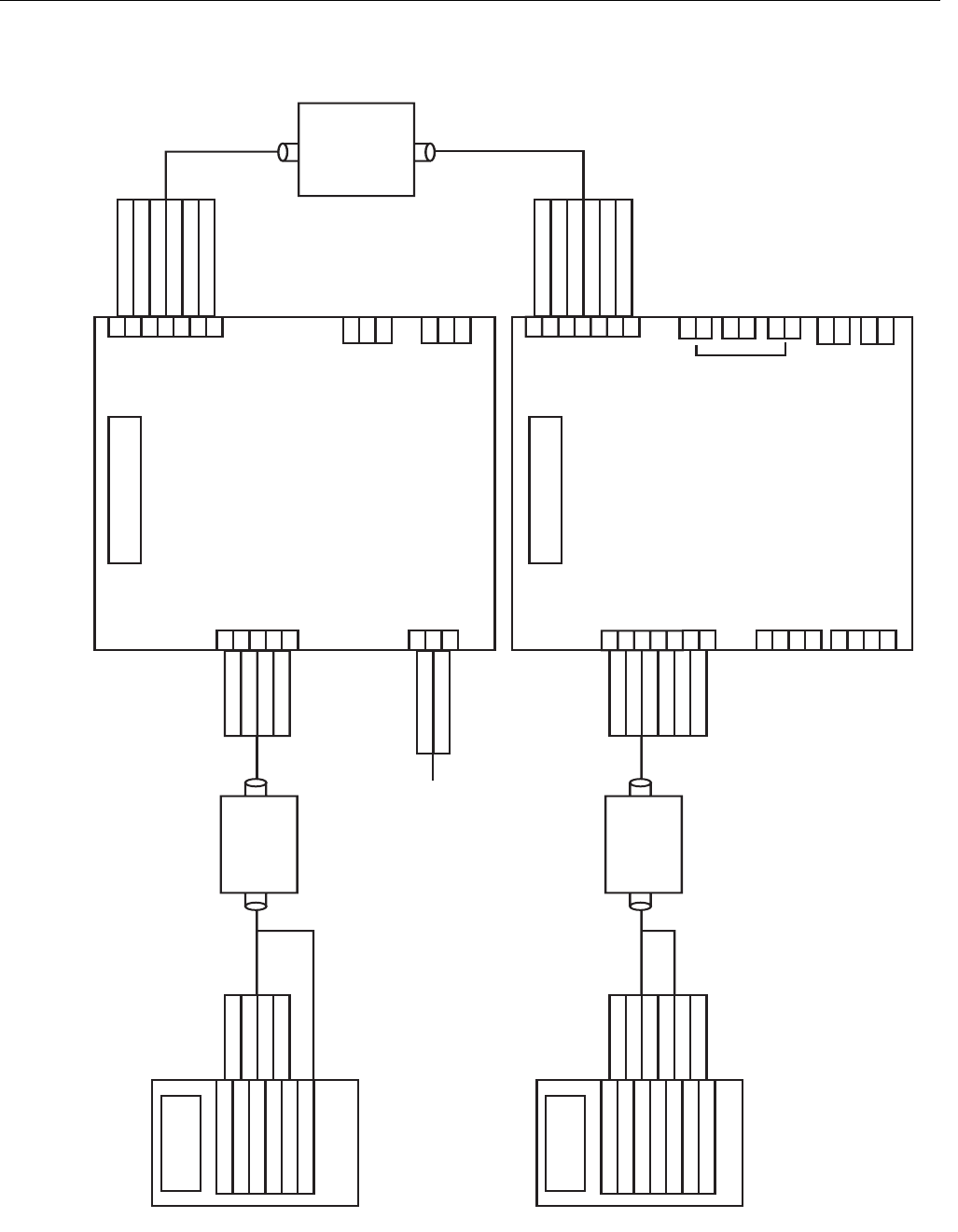

Figure 2-5. System Cable

Connections

MOTOR DIRECTION

MOTOR DRIVE

REFERENCE WAVE

0V TO SOURCE

12V TO SOURCE

SCREEN

YELLOW

PURPLE

BLACK/WHITE

RED/BROWN

TRANSMITTER

PVC COPPER

BRAID SCREEN

0.5 mm

8 CORE

2

YELLOW

PURPLE

BLACK/WHITE

RED/BROWN

8

9

10

11

12

BLUE

GREEN/YELLOW

BROWN

110V/220V

50-60Hz

SCREEN NOT TO BE GROUNDED

AT POWER SUPPLY

POWER SUPPLY

1

2

3

4

5

MOTOR DIRECTION

MOTOR DRIVE

REFERENCE WAVE

0V

+12V

6

7

ALARM CONTACT

DATA VALID CONTACT

COMMON

N/O

N/C

ALARM CONTACT

COMMON

N/O

N/C

PVC COPPER

BRAID SCREEN

0.5 mm

8 CORE

INTERCONNECT

CABLE

2

1

2

3

4

5

MOTOR DIRECTION

MOTOR DRIVE

REFERENCE WAVE

0V

DATA VALID

6

7

+12V SUPPLY

SIGNAL PROCESSOR

ALARM SIGNAL

TO POWER

SUPPLY

OXYGEN

4-20 mA (IN)

0V

TEMPERATURE

4-20 mA (IN)

0V

PRESSURE

4-20 mA (IN)

0V

NORMALIZING

INPUTS

8

9

10

11

12

13

PS2

+mA

0mA

PLANT STATUS

INPUT

ANALOG

OUTPUT

0V

+12V SUPPLY

D1 SIGNAL

SIGNAL 0V

TEMP INPUT

SOLENOID DRIVE

BLACK

WHITE

BLUE

GREEN

RECEIVER

PVC COPPER

BRAID SCREEN

0.5 mm

8 CORE

2

16

17

18

19

20

D2 SIGNAL

RED

YELLOW

PURPLE

SCREEN

BLACK

WHITE

BLUE

GREEN

RED

YELLOW

PURPLE

21

22

23

24

25

26

27

28

29

30

SERIAL DATA

SERIAL DATA

BLUE

BLUE

L

N

E

TX+

TX-

RX+

RX-

RX-

RX+

TX-

TX+

PS1

W1

O1

C1

W2

O2

C2

DATA VALID

TO SIGNAL

PROCESSOR

SCREEN NOT TO BE GROUNDED

AT SIGNAL PROCESSOR