4. LUBRICATION

RH-981A

26

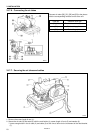

Oiling the looper, spreader and looper base

<Removing the work clamp plates>

1. Turn the upper shaft pulley (1) toward you until the mark on the pulley (A) is aligned with the notch in the pulley

cover (2).

2. Move the feed bracket (3) toward you.

3. Turn the left and right plate pressers (4) in the directions indicated by the arrows.

4. Lift up the clamp lever (6) and the notched section (7) of the right work clamp plate (5), remove the right work

clamp plate (5) from the pin (8), and then pull the right work clamp plate (5) toward you to remove it.

Note: If the lower thread trimmer has been installed, move presser plate U (9) to a position where it can be

removed without its touching the needle.

Raise presser plate U (9), pass the needle through the hole, and then remove presser plate U (9) from the

pin (8).

5. Remove the left work clamp plate (10) in the same way as the right work clamp plate (5) was removed.

6. Open the front cover.

7. Turn the looper base and add a few drops of oil to the spreader driving cam (11), and to the supports for the

looper link (12) and spreader link (13).

8. Add a few drops of oil to the shafts of the right spreader (14), left spreader (15) and LS-holder bracket (16).

9. Fill the felt tank (17) on the looper base with oil also.

10. Add 5 - 6 drops of oil to the felt (18) which is attached to the sliding surfaces of the looper base and the bed.

11. Close the front cover.

12. Install the work clamp plates by carrying out the steps 5., 4. and 3. in that order.

3031Q

3030Q

3032Q

0865Q 3033Q

3034Q

3035Q