–61–

3) Check the refrigerant volume by LED monitor display using the LED.

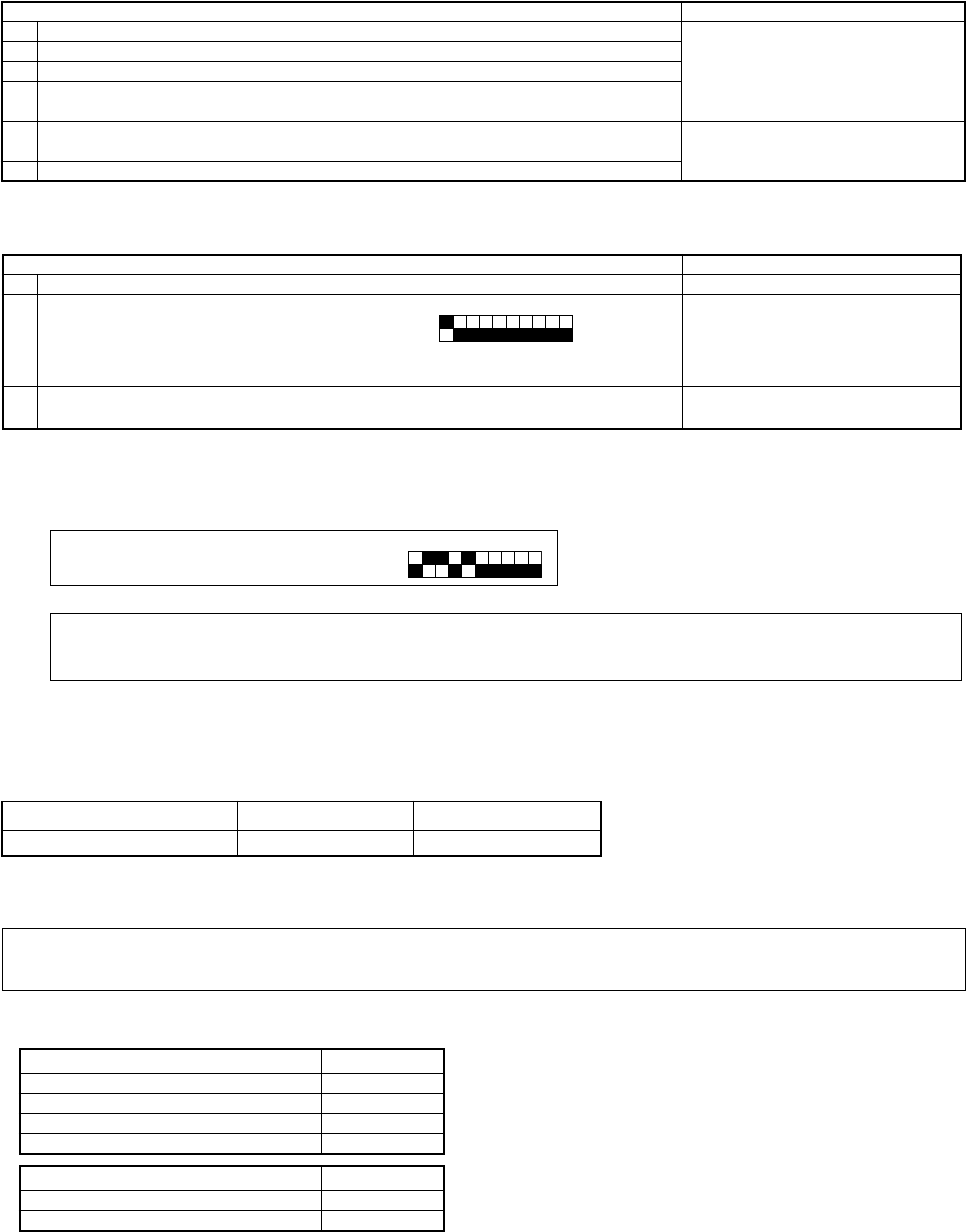

Set the LED monitor display switch (SW1) as shown below and check the past information (history) concerning the

refrigerant volume.

Set SW1 as shown in he figure at right.

If LD3 lights up, it indicates the refrigerant charge abnormal delay state just before emergency stop due to refriger-

ant overcharge (1500).

In the calculation results, round up fractions smaller than 0.01 kg. (Example: 18.54 kg → 18.6 kg)

L

1: Length of ø25.4 high press pipe (m)

L2: Length of ø12.7 liquid pipe (m)

L3: Length of ø9.52 liquid pipe (m)

L

4: Length of ø6.35 liquid pipe (m)

α1:refer to the calculation table.

Judgment

Refrigerant volume tends toward

insufficient.

Refrigerant volume tends toward

overcharge.

Check Items Judgment

12345678910

ON

Condition

1 Discharge temperature is high. (125°C or higher)

2 Low pressure saturation temperature is extremely low.

3 Inlet superheating is high (if normal, SH = 20 deg. or lower).

4 Shell bottom temperature is high (the difference with the low pressure saturation

temperature is 70 deg. or greater)

5 Shell temperature is low (the difference with the low pressure saturation temperature is

10 deg. or lower).

6 Liquid level AL = 2

Normal if the resistance is 2.8 kΩ ± 7 %.

Normal if AC 198 ~ 264 V is output

together with the LED lighting.

1 Liquid Heater Disconnection Check

2 Liquid Heater Output Check

Turn 1 ON on the LED monitor display switch (SW1)

12345678910

ON

, and output

the signal for the heater relay to LED 5, then check the voltage of the heater terminal (AC

198 ~ 264 V) (leave the heater connections as they are).

3 Use the LED monitor display to check if there is misalignment between the actual

temperature and the detected temperature of TH2 ~ TH4.

(2) Refrigerant Volume

1) Checking the Operating Condition

Operate all the indoor units in cooling or in heating, checking the discharge temperature, sub-cooling, low pressure

saturation temperature, inlet temperature, shell bottom temperature, fluid level, fluid step, etc. and rendering an overall

judgment.

Note:

Depending on the operating state, AL = 0 does not mean that there is insufficient refrigerant.

2) Cautions When Judging the Liquid Level

If you are judging the liquid level, be sure the liquid level sensor function (sensor and heater) are operating normally.

(α Calculation Table)

Total Capacity of Connected Indoor Units α1

161 ~ 330 2.0 kg

331 ~ 480 2.5 kg

481 ~ 630 3.0 kg

631 ~ 4.0 kg

(3) Additional Refrigerant Charge Volume

At the time of shipping from the factory, the outdoor unit is charged with the amount of refrigerant shown in the

following table, but since no extension piping is included, please carry out additional charging on-site.

Additional Refrigerant Volume (kg) = (0.31 × L1) + (0.12 × L2) + (0.06 × L3) + (0.024 × L4) + α1 + α2

(Note 1)

Calculation Formula

Calculate the additional refrigerant volume by calculating the size of the extension liquid piping and its length (units: m).

Outdoor Unit Model PURY-P400YMF-C PURY-P500YMF-C

Refrigerant Charge Volume 20 kg 22 kg

α2

BC controller (master) only 0 kg

BC controller (slave) connected 3.0 kg

(Note 1) : In case high press pipe size (L1) is

ø22.22, 0.25 × L1.