–30–

(3) Check points for test run when mounting options

(4) Attention for mounting drain water lifting-up mechanism

Built-in optional parts Content of test run Check point Result

Mounting of drain

water lifting-up

mechanism

Mounting of perme-

able film humidifier

Release connector of pump circuit,

check error detection by pouring water

into drain pan water inlet.

After that, connect connector of

circuit.

Check pump operations and drainage

status in cooling (test run) mode.

Check humidifier operations and

water supply status in heating (test

run) mode.

Local remote controller displays code No.

“2503”, and the mechanism stops.

No overflow from drain pan.

Drain water comes out by operations of

drain pump.

Sound of pump operations is heard, and

drain water comes out.

No water leak from connecting portions

of each water piping.

Water is supplied to water supply tank,

and float switch is operating.

Work Content of test run Check point Result

Disassembling and

assembling of drain

water lifting-up

mechanism

Mounting of float

switch

Electric wiring

Lead wire from control box not

damaged.

Rubber cap properly inserted to drain

water outlet of drain pan?

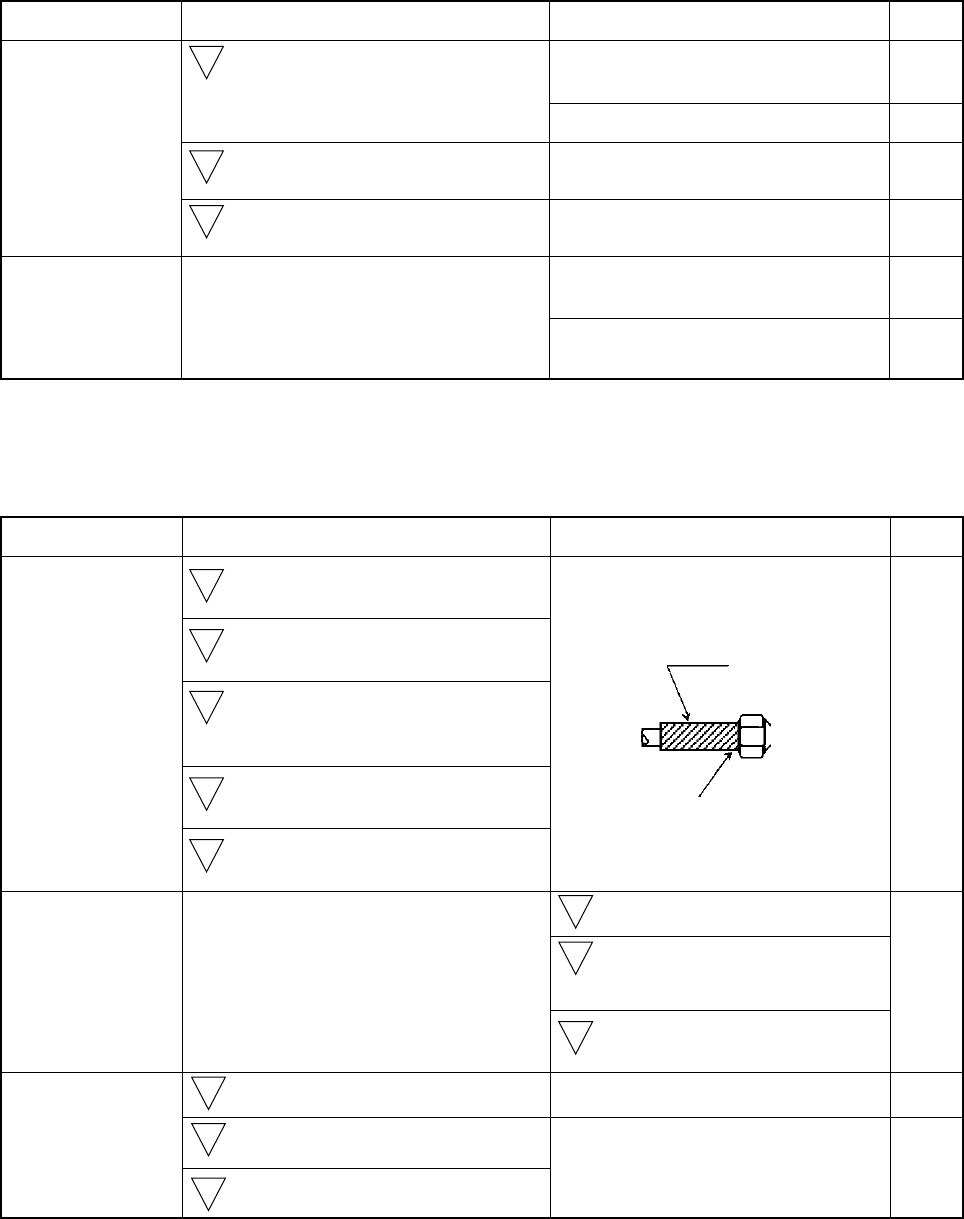

Insulation pipe of gas and liquid pipes

dealt with as shown in the right

figure?

Drain pan and piping cover mounted

without gap?

Drain pan hooked on cut projection of

the mechanism?

Float switch installed without contacting

with drain pan?

No mistakes in wiring?

Connectors connected securely and

tightly?

No tension on lead wire when sliding

control box?

Float switch moves smoothly.

Float switch is mounted on mount-

ing board straight without deforma-

tion.

Float switch does not contact with

copper pipe.

Wiring procedure is exactly followed.

Connector portion is tightly hooked.

1

2

3

1

2

3

4

5

1

2

3

1

2

3

No gap

Insulation pipe