–109–

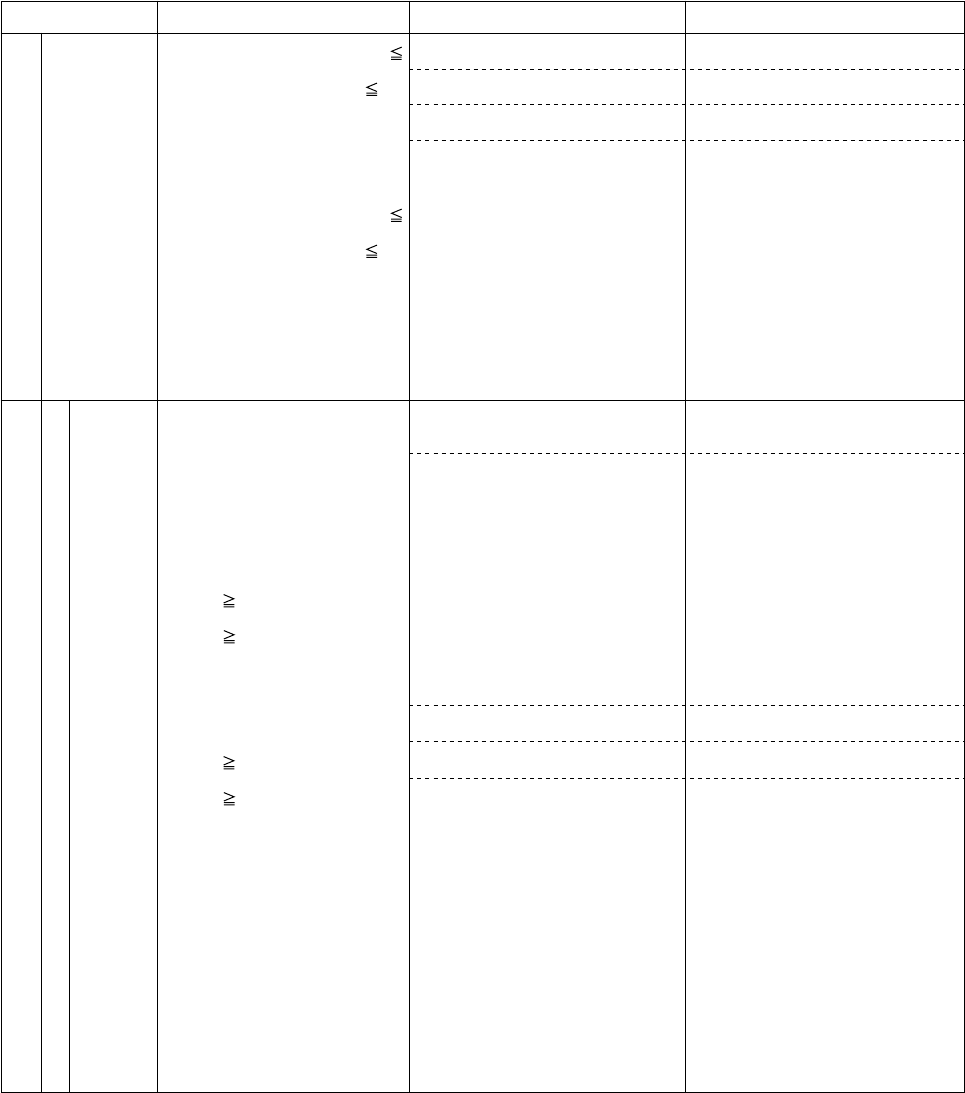

Checking code Meaning, detecting method Cause Checking method

1500

1501

Insufficient refrigerant abnormality

1.

When discharge superheart

10 deg is keeping for 10 minutes

or discharge superheat 20

deg for 15 minutes, outdoor unit

stops once, and after 3 minutes,

the unit restarts.

For 60 minutes after unit stopped

is intermittent fault check period.

2.

When discharge superheart

10 deg is keeping for 10 minutes

or discharge superheat 20

deg for 15 minutes again (sec-

ond time), the unit stops and er-

ror code 1500 is

displayed.

3.

In case of SW2-6 ON, the de-

tection for the second time is fol-

lowed by the first time.

1. When the unit condition is as

follows, the compressor is

stopped (1st detection) and af-

ter 3 minutes, the compressor

is restarted automatically.

PUHY-P200·250YMF-C

1 F<60Hz and TH10>85°C

continuously for 60 minutes.

2 F<60Hz and TH10>95°C

continuously for 15 minutes.

3 F 60Hz and TH10>100°C

continuously for 60 minutes.

4 F 60Hz and TH10>110°C

continuously for 15 minutes.

PURY-P200·250YMF-C

1 F<60Hz and TH10>85°C

continuously for 60 minutes.

2 F<60Hz and TH10>95°C

continuously for 15 minutes.

3 F 60Hz and TH10>100°C

continuously for 60 minutes.

4 F 60Hz and TH10>110°C

continuously for 15 minutes.

2.

If the temperature rises again as

above within 2 hours after the out-

door unit is stopped (2nd detection),

an error stop is performed, and the

check code 1501 is displayed.

3.

If the temperature rises again as

above within 2 hours after the out-

door unit is stopped, it becomes the

first detection again, and operation

is the same as in 1 above.

4.

The 2 hour period after the outdoor

unit stops is the abnormal delay pe-

riod, and LED display is carried out

during the abnormal stop delay.

Overcharged

refrigerant

abnormality

Lacked

refrigerant

abnormal-

ity

1) Excessive refrigerant charge.

2) Thermistor trouble (TH1).

3) Pressure sensor trouble (63HS).

4) Control circuit board trouble.

Check refrigerant amount.

Check resistance of thermistor.

See trouble shooting of pressure sensor.

Check temperature and pressure sen-

sor with LED monitor.

1) Gas leakage, insufficient gas.

2) Overload operation.

3) Indoor unit LEV operation is faulty.

4) Outdoor unit SLEV operation is

faulty.

5) Ball valve operation is faulty.

6) The thermistor is faulty.

7) The control board’s thermistor in-

put circuit is faulty.

Refer to the item on judging the refrig-

erant volume.

Check the indoor and outdoor unit op-

erating conditions.

Actually run the equipment in cooling

or heating mode and check the operat-

ing condition.

Cooling : Indoor unit LEV

SLEV

Heating : Indoor unit LEV

SLEV

Refer to the item concerning judging

LEV failure.

Check with the ball valve fully open.

Check the thermistor’s resistance.

Check the sensor’s temperature read-

ing by the LED monitor.