5

C07075

Fig. 6 -- Supply--Fan Pulley Adjustment

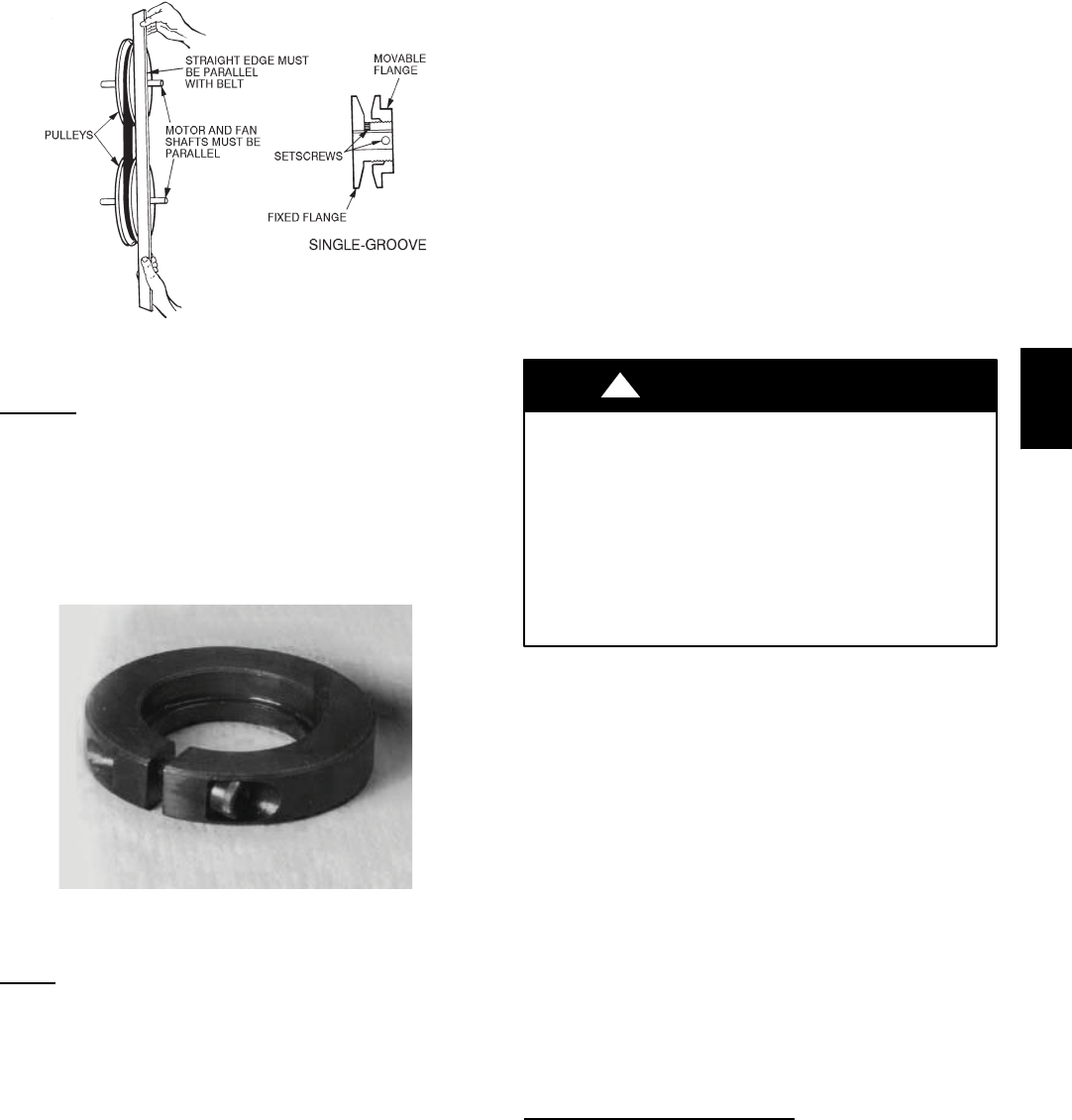

Beari ngs

This fan system uses bearings featuring concentric split

locking collars. The collars are tightened through a cap

screw bridging the split portion of the collar. The cap

screw has a Torx T25 socket head. To tighten the locking

collar: Hold the locking collar tightly against the inner

race of the bearing and torque the cap screw to 65--70

in--lb (7.4-- 7.9 Nm). See Fig. 7.

C08121

Fig. 7 -- Tightening Locking Collar

Motor

When replacing the motor, also replace the e xternal--tooth

lock washer (star washer) under the motor mounti ng base;

this is part of the motor grounding system. Ensure the

teeth on the lock washer are in contact with the motor’s

painted base. Tighten motor mounting bolts to 120 +/-- 12

in--lbs.

Changing fa n wheel speed by changing pulle ys: The

horsepower rating of the belt is primarily dictated by the

pitch diameter of the smaller pulley in the drive system

(typically the motor pulley in these units). Do not install a

replacement motor pulley with a smaller pitch diameter

than provided on the original factory pulley. Change fan

wheel speed by changing the fan pulley (larger pitch

diameter to reduce wheel speed, smaller pitch diameter to

increase wheel speed) or select a new system (both

pulleys and matching belt(s)).

Before changing pulleys to increase fan wheel speed,

check the fan performance at the target speed and airflow

rate to determine new motor loading (bhp). Use the fan

performance tables or use the Packaged Rooftop Builder

software program. Confirm that the motor in this unit is

capa ble of operating at the new operating conditi on. Fan

shaft loading increases dramatically as wheel speed is

increased.

To reduce vibration, replace the motor’s adjustable pitch

pulley with a fixed pitch pulley (after the final airflow

bala nce adjustment). This will reduce the amount of

vibration generated by the motor/belt--drive system.

COOLING

UNIT OPERATION AND SAFETY HAZARD

Failure to foll ow this warning could cause personal

injury, death and/or equipment damage.

This system uses PuronR refrigerant which has

higher pressures than R--22 and other refrigerant s. No

other refrigerant may be used in this system. Gauge

set, hoses, and recovery system must be designed to

handle Puron refrigerant. If unsure about equipment,

consult the equipment manufacturer.

!

WARNING

Condenser Coil

The condenser coil is fabricated with round tube copper

hairpins and plate fins of various material s and/or coatings

(see Model Number Format in the Appendix to identify

the materials provided in this unit). The coil may be

one--row or composite--type two--row. Composite two--row

coils are two single--row coils fabricated with a single

return bend end tubesheet.

Condenser Coil Maintenance and Cleaning

Recommendation

Routine cleaning of coil surfaces is essential to maintain

proper operation of the unit. Elimination of contamination

and removal of harmful residues will greatly increase the

life of the coil and extend the life of the unit. The

following maintenance and cleaning procedures are

recommended as part of the routine maintenance activities

to extend the life of the coil.

Remove Surface Loaded

Fibers

Surface loaded fibers or dirt should be removed with a

vacuum cleaner. If a vacuum cleaner is not available, a

soft non--metallic bristle brush may be used. In either

case, the tool should be applied in the direction of the fins.

Coil surfaces can be easily damaged (fin edges can be

easily bent over and damage to the coating of a protected

coil) if the tool is applied across the fins.

NOTE: Use of a water stream, such as a garden hose,

against a surface loaded coil will drive the fibers and dirt

into the coil. This will make cleaning efforts more

580J