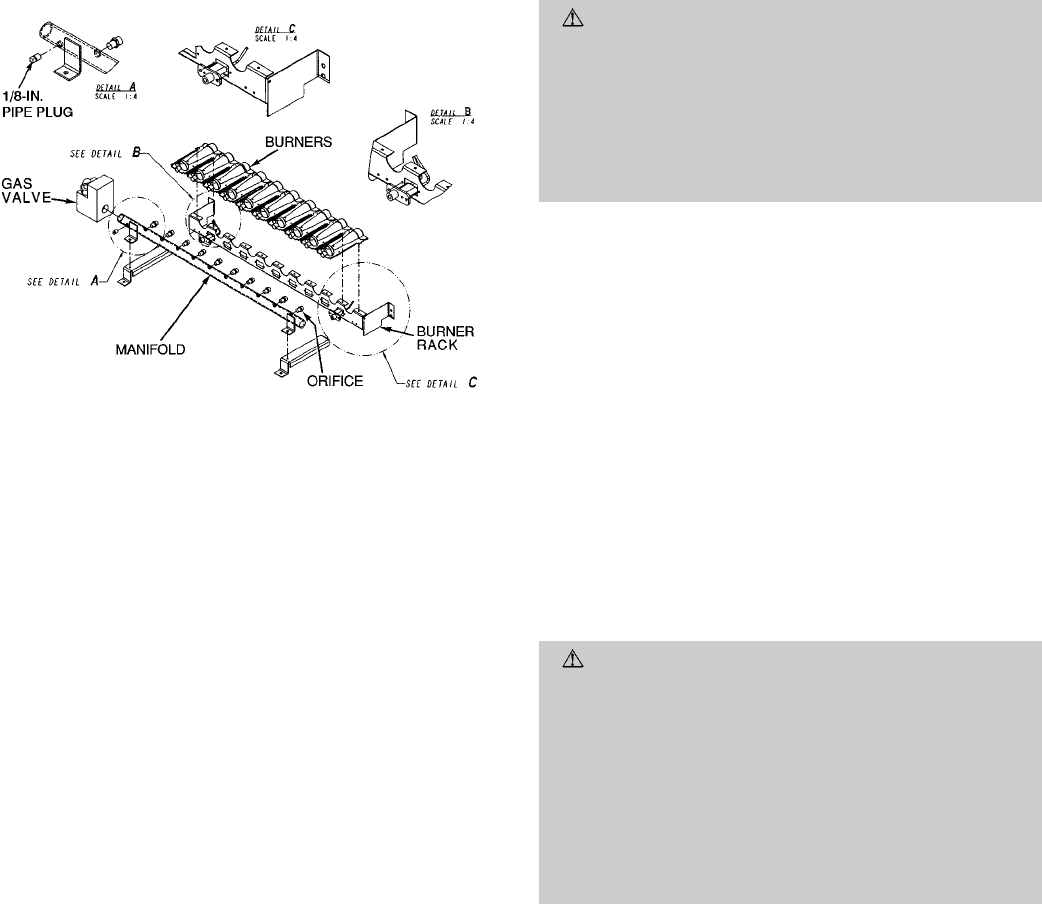

VI. MAIN BURNERS

For all applications, main burners are factory set and should

require no adjustment.

A. Main Burner Removal (Fig. 38)

1. Shut off (field-supplied) manual main gas valve.

2. Shut off power to unit.

3. Remove heating access panel.

4. Disconnect gas piping from gas valve inlet.

5. Remove wires from gas valve.

6. Remove wires from rollout switch.

7. Remove sensor wire and ignitor cable from IGC board.

8. Remove 2 screws securing manifold bracket to basepan.

9. Remove 4 screws that hold the burner support plate

flange to the vestibule plate.

10. Lift burner assembly out of unit.

VII. POWER EXHAUST OPERATION

The power exhaust packages are factory- or field-installed with

vertical units and optionally installed in the return air duct-

work for horizontal applications. The standard and the modu-

lating power exhaust are the two packages offered. The

modulating power exhaust package is equipped with a field-

adjustable static pressure controller to stage up to 4 power

exhausts stages which will maintain a building static pres-

sure. The blue sequencer located in the control box below the

control board can be adjusted, by removing the covers and

adjusting the set point dial to the desired building pressure.

The standard power exhaust package controls up to 2 stages

of power exhaust to maintain building pressure. These power

exhaust stages are staged according to a percentage of the

economizer dampers position.

VIII. HEAD PRESSURE CONTROL

Each unit has a fan cycling, outdoor thermostat to shut off

the outdoor-fan motor at 55 F. The head pressure control per-

mits unit to operate with correct condensing temperatures

down to 35 F outdoor-air temperature.

IX. LOW AMBIENT KIT

Low Ambient Kit is a fan speed control device actuated by

a temperature sensor. The field-installed accessory is specifi-

cally designed for use on this equipment and controls the

condenser-fan motor speed in response to the saturated

condensing temperature. For outdoor temperatures down to

−20 F, it maintains condensing temperature at 100 F.

CARE AND MAINTENANCE

To ensure continuing high performance, and to minimize the

possibility of premature equipment failure, periodic mainte-

nance must be performed on this equipment. This combina-

tion heating/cooling unit should be inspected at least once each

year by a qualified service person.

NOTE TO EQUIPMENT OWNER: Consult your local dealer

about the availability of a maintenance contract.

WARNING:

The ability to properly perform mainte-

nance on this equipment requires certain expertise,

mechanical skills, tools, and equipment. If you do not

possess these, do not attempt to perform any mainte-

nance on this equipment other than those procedures

recommended in the User’s Manual. FAILURE TO HEED

THIS WARNING COULD RESULT IN SERIOUS PER-

SONAL INJURY AND POSSIBLE DAMAGE TO THIS

EQUIPMENT.

The minimum maintenance requirements for this equipment

are as follows:

1. Inspect air filters each month. Clean or replace when

necessary.

2. Inspect cooling coil, drain pan, and condensate drain each

cooling season for cleanliness. Clean when necessary.

3. Inspect blower motor and wheel each heating and

cooling season. Clean and lubricate (if required) when

necessary.

4. Lubricate bearings every 6 months if fan runs continu-

ously or annually if fan runs intermittently.

5. Check electrical connections for tightness and controls

for proper operation each heating and cooling season.

Service when necessary.

6. Check and inspect heating section before each heating

season.

7. Check and clean vent screen if needed.

WARNING:

Failure to follow these warnings could re-

sult in serious personal injury:

1. Turn off electrical power to the unit before perform-

ing any maintenance or service on the unit.

2. Use extreme caution when removingpanels and parts.

As with any mechanical equipment, personal injury

can result from sharp edges, etc.

3. Never place anything combustible either on, or in con-

tact with, the unit.

4. Should overheating occur, shut off the electrical

supply.

Fig. 38 — Main Burner Removal

—28—